- Chintamani Stainless Inc, 132, T.P. Streets, 6th Kumbharwada Lane, Mumbai- 400004, India

- Trophy Winning

- Ceritified ( ISO 9005-2010 )

Duplex Fastener

Chintamani Stainless Inc is ISO 9001:2008 certified manufacturer, supplier and exporter of Duplex fasteners in India and worldwide.The Duplex 2205 Fasteners are made up of 2205 stainless steel, which is the mostly commonly used duplex

grade. This is a nitrogen enhanced alloy of stainless steel, which comes with good corrosion resistance

properties. They show good resistance to different types of corrosion even in welded conditions.

The Duplex Stainless Steel Fasteners possess high strength, which is why they are useful in many

applications. But due to their increased hardenability, they have lower machinability. The strength of

the Duplex Bolts material also makes it difficult to bend or form them, they require a larger capacity

equipment than what is required for austenitic steel products.

The Duplex Hex Bolt material has good content of elements like chromium, molybdenum, and nickel in its

chemical composition, which is why they show good pitting resistance. In fact the Pitting Resistance

Equivalent (PERN) of the Duplex Threaded Rod is 35.8, which is quite high and exceeds that of 316 and

316L stainless steel grades. On heating, the microstructure of the Duplex Stud Bolts becomes such that

it is a perfect mixture of the austenite and ferrite phases.

The microstructure of the Duplex 2205 Hex Bolt is also responsible for its high corrosion resistance

capabilities in different types of environments. In fact, the Duplex 2205 Threaded Rod possesses

superior corrosion resistivity than other stainless steel grades like 316 or 317.

Bolts, ASTM A182 F51 UNS S31803 The material that makes up nuts is duplex grade. High-stress

applications like heat exchangers, pressure vessels, and chemical processing applications require these

bolts and nuts. These ASTM A182 f51 bolts and nuts come in a variety of sorts and dimensions, and Chintamani Stainless Inc is a top maker of them. Carbon, manganese, silicon, phosphorus, sulphur, 22% chromium, 3%

molybdenum, 4.5% nickel, nitrogen, and iron make up the substance.

With a minimum yield strength of 550 MPa, a minimum tensile strength of 800 MPa, a 15% elongation rate,

and a density of 7.8 grammes per centimetre cube, the uns s31803 bolt exhibits great strength. The ASTM

A182 and A479 requirements, which address high pressure and high temperature applications, apply to the

uns s31803 fasteners.

The dual crystallinity of a duplex grade stainless steel's microstructure accounts for its improved

qualities. In an annealed state, 50% of the microstructure of DIN 1.4462 Studs is composed of austenite

and ferrite. Therefore, the alloy of a Duplex steel UNS S32205 Fasteners astm a276/a479 UNS S32205 Bolts

has the characteristics of both crystalline metals concurrently. Because of the hardness of the ferrite

crystals and the flexibility of its austenite crystalline region, the alloy is easier to form into Astm

A479 Duplex Steel UNS S32205 Hex Bolts while maintaining its shape.

Specification

Specifications |

ASTM A 182 / ASME SA 182 |

Grade |

ASTM A182 GR.F51 |

Standard |

IN931, DIN933, ISO4014, ISO4017, ASTM, BS and all International Standards |

Length |

3 mm to 200 mm |

Nuts Size |

M3 – M56 | 3/6″ to 2″ | Custom Sizes |

Bolts / Screw Size |

M3 – M56 | 3/6″ to 2″ | Custom Sizes |

Standard |

DIN, UNI, ISO, JIS, GB, IS, BS, ASME, ANSI, ASTM and all International Standards |

Bolts, Studs Threads: |

METRIC, BSW, BSF, UNC, UNF or as required |

In Form of |

Hex, Square, Round, Threading as per Gauge Etc. |

Head drive |

Phillips, Slotted, Phillips/Slot, Six-Lobe, etc |

Bolts Size |

M2, M2.5, M3, M4, M5, M6, M8, M10, M12, M14, M16, M20, M24, M30, M36 to M160 |

Machine Screws Size |

M1.6 – M12 |

Washers Size |

M3 – M56 | 3/6″ to 2″ | Custom Sizes |

DIN 931 – Hexagon head bolts with shank |

Current norm: DIN EN ISO 4014 Equivalent norms: ISO 4014; CSN 021101; PN 82101; UNI 5737; EU 24014; |

DIN 933 – Hexagon head bolts with thread up to head. |

Current norm: DIN EN 24017. Equivalent norms: ISO 4017; CSN 021103; PN 82105; UNI 5739; EU 24017 |

Test Certificate: |

Manufacturer Test Certificate as per EN 10204 / 3.1 |

Source of raw materials |

Tata Steel, JSPL, RINL, Usha Martin, Dhamm Steel, Mukund Steel etc. |

Scope Of Manufacture |

|

Duplex Steel Grades |

Duplex Steel UNS S32205 |

Packing |

IN BULK: canton, pallet, Small Boxs / carton / pallet, or customer request |

Production process |

M2-M24: Cold Froging, hot forging M24-M100, machining and CNC for Customized connecting element |

Duplex S31803 Fasteners Standard: |

ANSI – American National Standards Institute

DIN: DIN 931, DIN 933, DIN 934, DIN 970 UTS – Unified Thread Standard : UNC, UNF, UNEF, UNS, NPT, NPTF ISO – International Organization for Standardization : ISO 4032, ISO 4033, JIS standards |

Fasteners Type |

Cap Screw, Machine Screw, Wing Screw, Spring Washers, Washers, Studs, Marine Anchors, Anchors, Hexagon Nut,U- Bolts, Anchor Bolt, Mushroom Head Square Neck Bolts, J Bolts,Eye Bolt,Structural Bolts, Bolts, Nuts, Sockets, Screws, Allen Cap screw,Nut, Hex Coupling Nut, Hex Nut, Square Nut, Hex Domed Cap Nuts, Hex Head Bolts, Stud Bolts, Socket Hexagon Head Screw, Pan Head Screw, Socket Head Cap Screw, Wing Screw, T-Head Bolts, Foundation Bolts,Screw, Studs, Socket Screw, Hex Set Screw |

ASTM A182 GR.F51 Fasteners Property Class

| For Bolts & Screws | A2-70, A2-80, A4-70, A4-80, F593C, F593D, F593G, F593H |

| For Nuts | A2-70, A2-80, A4-70, A4-80, F594C, F594D, F594G, F594H, A2-035, A4-040 |

| For SHCS | F837B, F837C, F837E, F837 |

| For Threaded Rods | A2-70, A2-80, A4-70, A4-80, F593C, F593D, F593G, F593H, B8, B8M CL1 & CL2 |

| Hexagon Bolts / Set Screws | Stud Bolts | Hexagon Nuts | Socket Cap Screws |

|---|---|---|---|

| DIN 931 | BS4882 | DIN 934 | DIN 912 |

| DIN 933 | DIN 976 | BS 1768 | DIN 6912 |

| BS 1768 | BS 1769 | DIN 7984 | |

| UNI 5731 | BS 1083 | ANSI B18.3 | |

| UNI 5739 | BS 3692 | ISO 4762 | |

| ISO 4014 | ISO 4032 | UNI 5931 | |

| ISO 4017 | ISO 4033 | BS 2470 | |

| BS 1769 | ANSI B18.2.2 | BS 4168 | |

| BS 3692 | |||

| ANSI B18.2.1 |

| Socket & Slotted Set Screws | Socket & Slotted Countersunk Screws | Studs | Washers |

|---|---|---|---|

| DIN 913 | DIN 963 | DIN 938 | DIN 125 |

| DIN 914 | DIN 7991 | DIN 939 | DIN 9021 |

| DIN 915 | BS 4168 | DIN 2510 | BS 4320 |

| DIN 916 | BS 1981 | BS 4439 | BS 3410 |

| DIN 551 | BS 483 | BS 2693 | |

| DIN 553 | BS 2470 | Spring Washers | |

| DIN 438 | DIN 127 | ||

| BS 4168 | BS 4464 | ||

| BS 1802 |

Standard Dimensions Of ASTM A1082 UNS S31803 Hex Nuts

| Thread Diameter Of Nominal Size Nut | Diameter Of (F) | Diameter Of (G) | Diameter Of (H) | ||||||

| Hex Nut Width Across Flats |

Hex Nut Width Across Corners |

Wall Thickness | |||||||

| Basic | Maximum | Minimum | Maximum | Minimum | Basic | Maximum | Minimum | ||

| 1/4 | .2500 | 7/16 | .438 | .428 | .505 | .488 | 7/32 | .226 | .212 |

| 5/16 | .3125 | 1/2 | .500 | .489 | .577 | .557 | 17/64 | .273 | .258 |

| 3/8 | .3750 | 9/16 | .562 | .551 | .650 | .628 | 21/64 | .337 | .479 |

| 7/16 | .4375 | 11/16 | .688 | .675 | .794 | .768 | 3/8 | .385 | .365 |

| 1/2 | .5000 | 3/4 | .750 | .736 | .866 | .840 | 7/16 | .448 | .427 |

| 9/16 | .5625 | 7/8 | .875 | .861 | 1.010 | .982 | 31/64 | .496 | .473 |

| 5/8 | .6250 | 15/16 | .938 | .922 | 1.083 | 1.051 | 35/64 | .559 | .535 |

| 3/4 | .7500 | 1-1/8 | 1.125 | 1.088 | 1.299 | 1.240 | 41/64 | .665 | .617 |

| 7/8 | .8750 | 1-5/16 | 1.312 | 1.269 | 1.516 | 1.447 | 3/4 | .776 | .724 |

| 1 | 1.0000 | 1-1/2 | 1.500 | 1.450 | 1.732 | 1.653 | 55/64 | .887 | .831 |

| 1-1/8 | 1.1250 | 1-11/16 | 1.688 | 1.631 | 1.949 | 1.859 | 31/32 | .999 | .939 |

| 1-3/8 | 1.3750 | 2-1/16 | 2.062 | 1.994 | 2.382 | 2.273 | 1-11/64 | 1.206 | 1.138 |

| 1-1/2 | 1.500 | 2-1/4 | 2.250 | 2.175 | 2.598 | 2.480 | 1-9/32 | 1.ASTM A194 GR. 8 | 1.245 |

| 1-5/8 | 1.6250 | 2-7/16 | 2.438 | 2.356 | 2.815 | 2.686 | 1-25/64 | 1.429 | 1.353 |

| 1-3/4 | 1.7500 | 2-5/8 | 2.625 | 2.538 | 3.031 | 2.893 | 1-1/2 | 1.540 | 1.460 |

| 2 | 2.0000 | 3 | 3.000 | 2.900 | 3.464 | 3.306 | 1-23/32 | 1.763 | 1.675 |

| 2-1/4 | 2.2500 | 3-3/8 | 3.375 | 3.263 | 3.897 | 3.719 | 1-15/16 | 1.986 | 1.890 |

| 2-1/2 | 2.5000 | 3-3/4 | 3.750 | 3.625 | 4.330 | 4.133 | 2-5/32 | 2.209 | 2.105 |

| 2-3/4 | 2.7500 | 4-1/8 | 4.125 | 3.988 | 4.763 | 4.546 | 2-3/8 | 2.431 | 2.319 |

| Nominal Size Of (D) | Body Diameter Of Bolts | Thickness Of Head | UNS S32760 Bolts Across The Flats | UNS S32760 Bolts Across Corners | ||||

|---|---|---|---|---|---|---|---|---|

| MAXIMUM (D) | MINIMUM (D) | MAXIMUM (H) | MINIMUM (H) | MAXIMUM (F) | MINIMUM (F) | MAXIMUM (C) | MINIMUM (C) | |

| Metric 10 | 10.00 | 9.78 | 6.63 | 6.17 | 17.00 | 15.73 | 18.48 | 17.77 |

| Metric 12 | 12.00 | 11.73 | 7.76 | 4.24 | 19.00 | 17.73 | 20.78 | 20.03 |

| Metric 14 | 14.00 | 13.73 | 9.09 | 8.51 | 22.00 | 20.67 | 24.25 | 23.35 |

| Metric 16 | 16.00 | 15.73 | 10.32 | 9.68 | 24.00 | 23.67 | 27.71 | 26.75 |

| Metric 20 | 20.00 | 19.67 | 12.88 | 12.12 | 30.00 | 29.16 | 34.64 | 32.95 |

| Metric 24 | 24.00 | 23.67 | 15.44 | 14.56 | 36.00 | 35.00 | 41.57 | 39.55 |

| Metric 30 | 30.00 | 29.67 | 19.48 | 17.92 | 46.00 | 45.00 | 53.12 | 50.85 |

| Metric 36 | 36.00 | 35.61 | 23.38 | 21.63 | 55.00 | 53.80 | 63.51 | 60.79 |

| Metric 42 | 42.00 | 41.38 | 26.97 | 25.03 | 65.00 | 62.90 | 75.06 | 71.71 |

| Metric 48 | 48.00 | 47.38 | 31.07 | 28.93 | 75.00 | 72.60 | 86.60 | 82.76 |

| Metric 56 | 56.00 | 55.26 | 36.2 | 33.80 | 85.00 | 82.20 | 98.15 | 93.71 |

| Metric 64 | 64.00 | 63.26 | 41.32 | 38.68 | 95.00 | 91.80 | 109.70 | 104.65 |

| Metric 72 | 72.00 | 71.26 | 46.45 | 43.55 | 105.00 | 101.40 | 121.24 | 115.60 |

| Metric 80 | 80.00 | 79.26 | 51.58 | 48.42 | 115.00 | 111.00 | 132.72 | 126.54 |

| Metric 90 | 90.00 | 89.13 | 57.74 | 54.26 | 130.00 | 125.50 | 150.11 | 143.07 |

| Metric 100 | 90.00 | 99.13 | 63.9 | 60.10 | 145.00 | 140.00 | 167.43 | 159.60 |

Size Of S31803 Flat Washer |

USS |

SAE |

||||

|---|---|---|---|---|---|---|

I.D. (Inside Diameter) Of (A) |

O.D. (Outside Diameter) Of (B) |

Wall Thickness Of (C) |

I.D. Of (A) |

O.D. Of (B) |

Wall Thickness Of (C) |

|

#2 |

- |

- |

- |

3/32" |

1/4" |

0.020" |

#4 |

- |

- |

- |

1/8" |

5/16" |

0.032" |

#6 |

- |

- |

- |

5/32" |

3/8" |

0.049" |

#8 |

- |

- |

- |

3/16" |

7/16" |

0.049" |

Duplex 2205 Shoulder Bolts Equivalent

| grade | Common Name | Related Specifications | ||

|---|---|---|---|---|

| UNS | European DIN | ASTM/ASME | ||

| 2205 Duplex Stainless Steel Bolts | SAF 2205® | S31803/S32205 | 1.4462 | F51/F60 |

CHEMICAL COMPOSITION

| Grade | Fe | Mn | C | Si | S | P | Cr | Ni | Mo | N |

| S31803 | 63.72 min | 2.00 max | 0.030 max | 1.00 max | 0.020 max | 0.030 max | 22.0 – 23.0 | 4.50 – 6.50 | 3.0 – 3.5 | 0.14 – 0.20 |

| S32205 | 63.54 min | 2.00 max | 0.030 max | 1.00 max | 0.020 max | 0.030 max | 21.0 – 23.0 | 4.50 – 6.50 | 2.50 - 3.50 | 0.8 – 0.20 |

MECHANICAL PROPERTIES

| Duplex Bolts & Nuts | Tensile Strength | Melting Point | Density | Yield Strength (0.2%Offset) | Elongation |

| Psi – 116000 , MPa – 800 | 1350 °C (2460 °F) | 7.8 g/cm3 | Psi – 80000 , MPa – 550 | 15 % |

Duplex Stud Bolts Application

- Petrochemicals

- Aircraft Exhaust Manifolds

- Off-Shore Oil Drilling Companies

- Sea Water Equipment

- Pharmaceuticals

- Power Generation

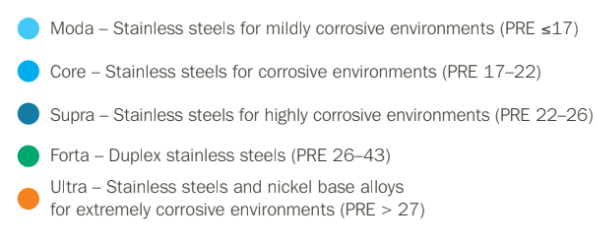

General characteristics

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2205 | 1.4462 | 2205 | S32205 | 35 | 20 | 500 | D | 0.02 | 22.4 | 5.7 | 3.1 | 0.17 |

| 2205 stainless steel grades | Industry Specifications | UNS |

Duplex 2205 2205 (EN 1.4462/UNS S32205 & S31803) |

• Cargo tanks in chemical tankers • Pulp and paper industry applications such as digesters and process tanks • Oil and gas industry, typically tubular products, flanges, fittings and valves • Structural components in bridges |

• Cold rolled coil and sheet • Hot rolled coil and sheet • Quarto plate • Bar • Wire rod • Semi-finished (bloom, billet, ingot & slab) |

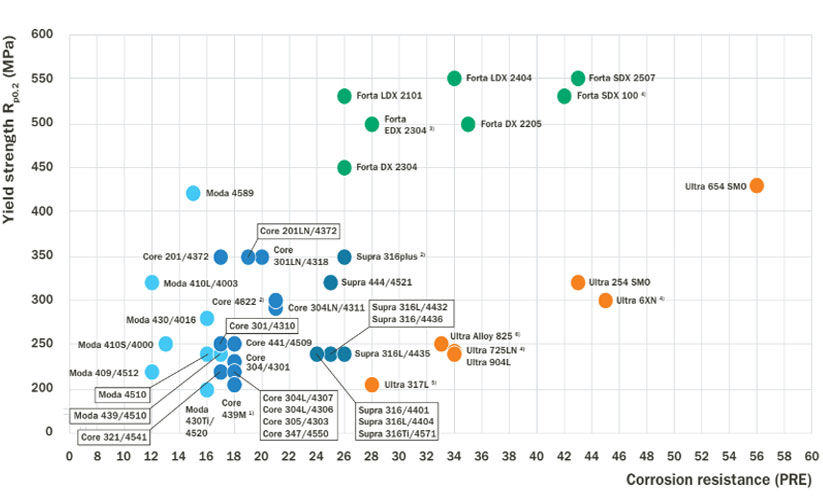

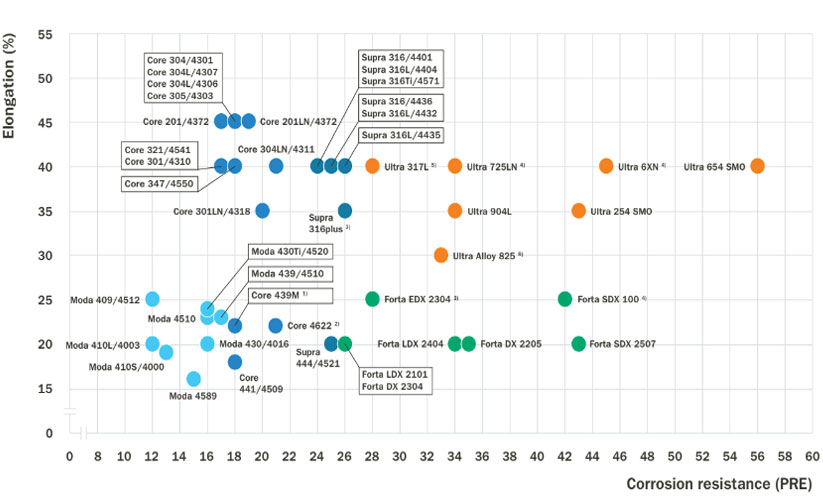

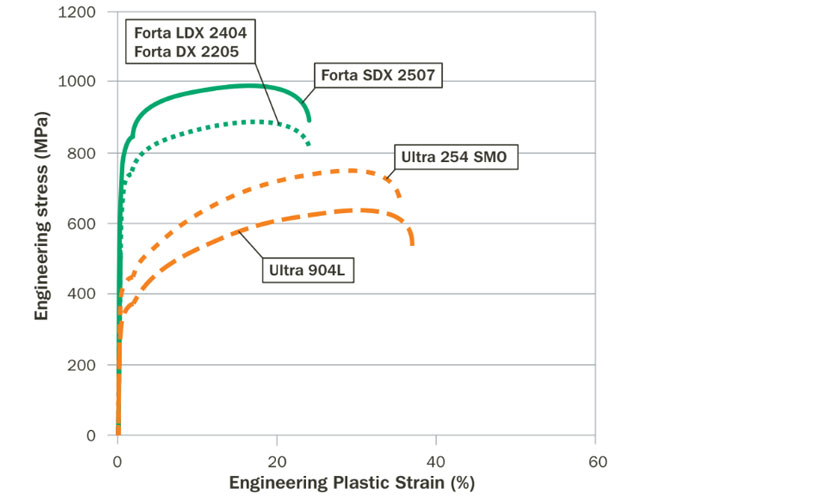

Performance

Elongation vs. corrosion resistance.

Elongation vs. Corrosion resistance

Strength vs. Corrosion resistance

Elongation vs. Corrosion resistance

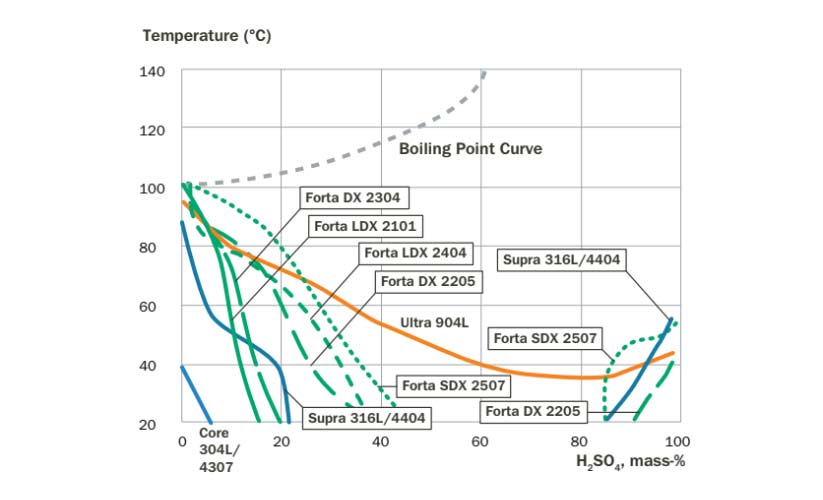

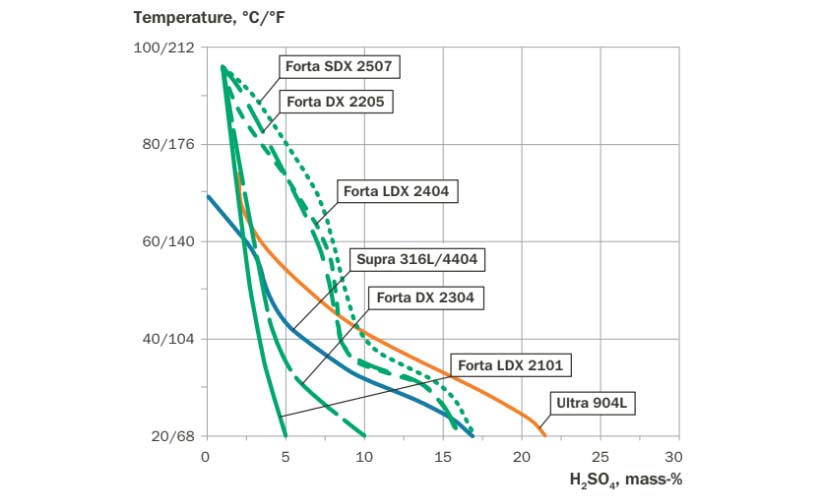

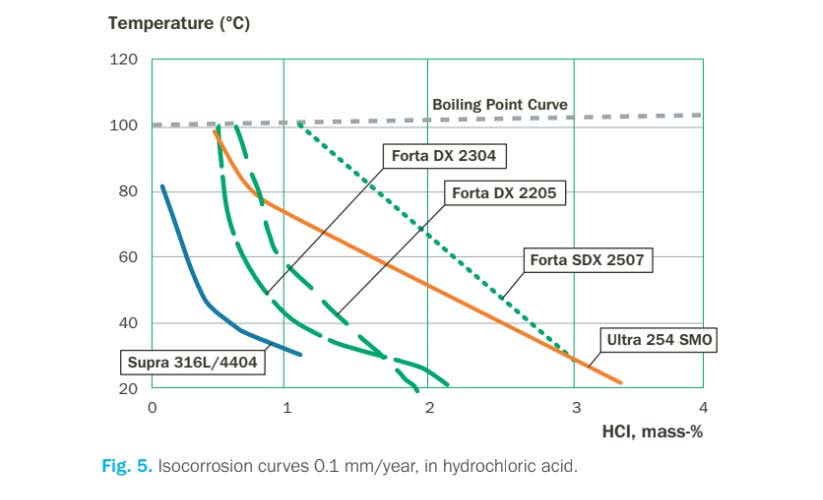

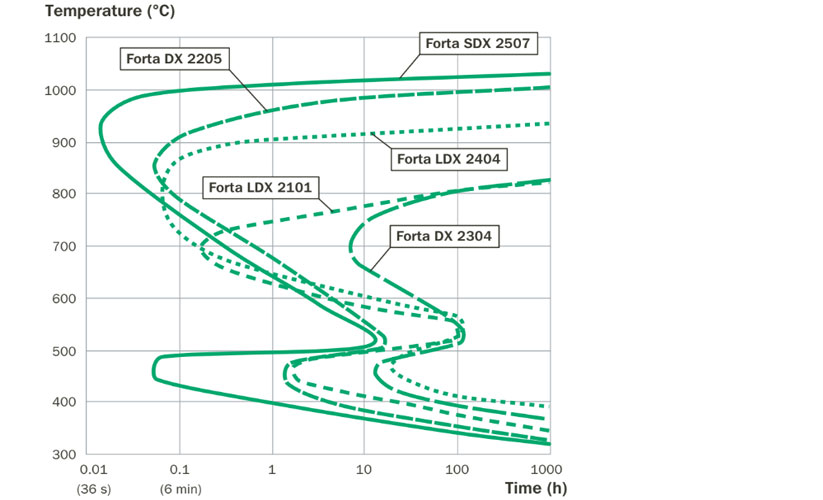

Duplex stainless steels, known for their high chromium content, provide excellent corrosion resistance, particularly in uniform corrosion environments with rates below 0.1 mm/year. Forta DX 2205 shows superior resistance to chloride-contaminated sulfuric acid compared to traditional stainless steels like Supra 316L/4404, approaching the performance of Ultra 904L. In dilute hydrochloric acid, Forta SDX 2507 and similar high-alloyed duplex steels are suitable, though localized corrosion risks exist around crevices even within safe usage limits.

Corrosion resistance

- Uniform Corrosion: Due to high chromium content, these steels resist uniform corrosion well, typically less than 0.1 mm/year.

- Sulfuric Acid: DX 2205 shows superior resistance in sulfuric acid contaminated by chloride ions compared to Supra 316L/4404.

- Hydrochloric Acid: SDX 2507 and DX 2205 can be used in dilute hydrochloric acid, with potential risks of localized corrosion in crevices.

- Nitric Acid: LDX 2101 and DX 2304, with their high chromium content and low molybdenum, are suitable for environments where resistance to strongly oxidizing nitric acid is needed.

PRE values for Forta Duplex grades and some austenitic grades

Steel designations |

PRE |

|||

| name | EN | ASTM Type |

UNS | |

| 2205 | 1.4462 | 2205 | S32205 | 35 |

Results from stress corrosion cracking immersion tests in chloride solutions

| name | ASTM G123 | ASTM G36 | ||

| 25% NaCl, pH 1.5, 106°C (b.p.), 1,000 h | 40% CaCl2, 100°C, 500 h | 45% MgCl2, 155°C (b.p.), 24 h | ||

| U-bend samples | 4-PB samples (90% of Rp0.2) | U-bend samples | ||

| 2205 | No SCC | No SCC | SCC | |

Mechanical properties according to EN 10088 and EN 10028

| EN | ASTM | Product form | Yield strength | Tensile | Elongation | Elongation | |

| name | UNS | Rp0.2[MPa] | strength | A[%] | A80[%] | ||

| Rm[MPa] | |||||||

| 2205 | 1.4462 | S32205 | Cold rolled coil (C) | 500 | 700–950 | 20 | 20 |

| Hot rolled coil (H) | 460 | 700–950 | 25 | 25 | |||

| Quarto plate (P) | 460 | 640–840 | 25 | 25 | |||

| Wire rod 1) | 510 | 750 | 35 | – | |||

| Bar | 450 | 650–880 | 25 | – |

Mechanical properties according to ASTM A240

| EN | ASTM | Product form | Yield | Yield | Tensile | Tensile | Elongation | |

| name | UNS | strength | strength | strength | strength | A50[%] | ||

| Rp0.2[MPa] | Rp0.2 [ksi] | Rm [MPa] | Rm [ksi] | |||||

| 2205 | 1.4462 | S32205 | Plate, sheet and strip | 450 | 65 | 655 | 95 | 25 |

| Wire rod 1) | 510 | 74 | 752 | 109 | – |

Mechanical properties at elevated temperatures, minimum yield strength according to EN 10028-7

| name | Strength | 100°C | 150°C | 200°C | 250°C | |

| 2205 | Yield strength | Rp0.2 [MPa] | 360 | 335 | 315 | 300 |

| Tensile strength | Rm [MPa] | 590 | 570 | 550 | 540 | |

Physical properties

Metric values according to EN 10088-1

| name | EN | ASTM Type | UNS | Density [kg/dm3] | Modulus of elasticity at 20°C [GPa] | Coefficient of thermal expansion 20–100°C [10-6/K] | Thermal conductivity at 20°C [W/(m x K)] | Thermal capacity at 20°C [J/(kg x K)] | Electrical resistivity at 20°C [Ω x mm2/m] |

| 2205 | 1.4462 | 2205 | S32205 | 7.8 | 200 | 13.0 | 15 | 500 | 0.8 |

Imperial values converted from Table 10

| name | Density [lbm/in3] | Modulus of elasticity [psi] | Coefficient of thermal expansion 68–212°F [μin / (in x °F)] | Thermal conductivity [Btu/(hr x ft x °F)] | Thermal capacity [Btu/(lbm x °F)] | Electrical resistivity [μΩ x in] |

| 2205 | 0.282 | 29 x 106 | 7.2 | 8.7 | 0.119 | 31.50 |

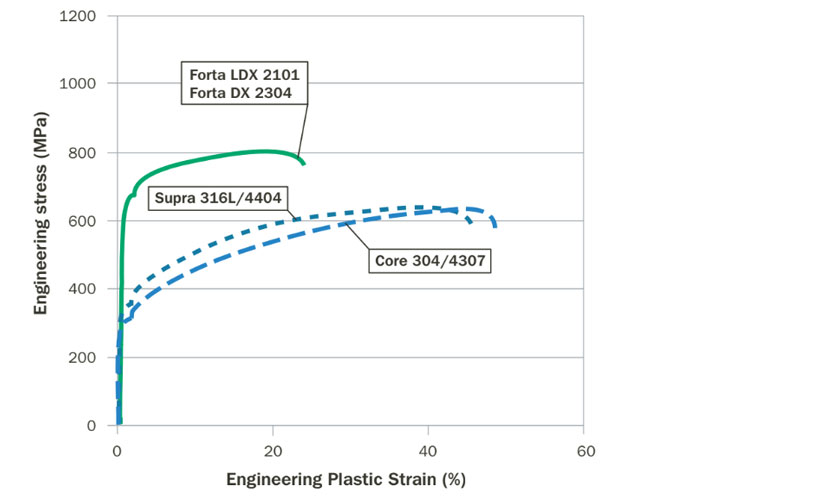

Fabrication

Duplex stainless steel is suitable for all forming processes used for stainless steel. The high yield strength compared to austenitic and ferritic stainless steel can however give differences in forming behavior. Depending on the chosen forming technique there could be consequences, such as increased springback. This point is particularly relevant to the forming of any high strength steel. Moreover, an excellent interplay between high yield strength, work hardening rate and elongation promote the duplex grades for light weight and cost-efficient applications with complex shapes. The impact of the high strength varies for different forming techniques. Common for all is that the estimated forming forces will be higher than for the corresponding austenitic and ferritic stainless steel grades. This effect will usually be lower than expected from just the increase in strength since the choice of duplex stainless steel is often associated with gauge reduction. It is important to consider that duplex stainless steel may also be more demanding on the tools and on the lubricant. This should also be noted when looking to down gauge.

Welding consumables

| name | EN | ASTM Type | UNS | Consumable ISO designation |

| 2205 | 1.4462 | 2205 | S32205 | 22 9 3 NL |

General characteristics

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2205 | 1.4462 | 2205 | S32205 | 35 | 20 | 500 | D | 0.02 | 22.4 | 5.7 | 3.1 | 0.17 |

Product

Quick contact

Get Solution

Organically grow the holistic world view of disruptive innovation via workplace diversity

Contact Us