- Chintamani Stainless Inc, 132, T.P. Streets, 6th Kumbharwada Lane, Mumbai- 400004, India

- Trophy Winning

- Ceritified ( ISO 9005-2010 )

Duplex Pipes & Tube

Chintamani Stainless Inc is ISO 9001:2008 certified manufacturer, supplier and exporter of Duplex Pipes & Tubes in India and worldwide .Duplex 2205 pipe has multiple uses, including oil and gas exploration and transportation,

power generation, and offshore oil drilling companies. Duplex 2205 Stainless Pipe &

Condensers Tube, Petrochemicals, Gas Processing, Heat exchangers, Pipe for Sea Water

Equipment,Pharmaceutical Equipment, Cooling pipe,Structural and mechanical components,

Chemical Equipment. Duplex 2205 tubes are used in boilers and heat exchangers, as well

as oil tubes, fluid tubes, and gas tubes.

As the 2205 duplex stainless tubing component is subjected to temperatures over 572°F,

particularly though the exposure is brief, the duplex 2205 seamless tube becomes

embrittled. As a result, 2205 duplex pipe can not be used at temperatures above 572°F.

Due to higher chromium, molybdenum, and nitrogen contents, 2205 duplex stainless steel

tubes exhibit superior corrosion resistance properties in most settings as compared to

the more commonly used austenitic stainless steel grades 316 and 316L.

The corrosion-resistant duplex stainless steel S31803 is used to make Sa789 S31803

Coiled Tubings. Control phase, chemical injection line, electrical line, multi-line flat

pack, hydraulic line, tube encapsulated conductor, intelligent well completions, and

capillary tubing are several of the applications. Sa789 S32205 boiler tubes are those

with the ability to withstand extreme pressure and temperature.

Alloy 2205 is a second-generation, nitrogen-alloyed duplex stainless steel (ferritic-austenitic). It

offers an excellent combination of both strength and corrosion resistance over a wide range of

applications. The approximate 50/50 ferrite-austenite structure provides excellent chloride pitting and

stress corrosion cracking resistance, with roughly twice the yield strength of the standard austenitic

stainless grades.

The high chromium and molybdenum content, coupled with the nitrogen addition in 2205, provides general

corrosion, pitting, and crevice corrosion resistance superior to 316L and 317L.

The UNS S31803 grade stainless steel has undergone a number of modifications resulting in UNS S32205,

and was endorsed in the year 1996. This grade offers higher resistance to corrosion.

2205 demonstrates superior erosion-corrosion resistance when compared to 316 stainless steel. It is not

subject to intergranular corrosion in the as-welded condition. 2205 may be successfully machined by

conventional methods.

The (UNS S32205) grade is a restricted-chemistry version which maintains chromium, molybdenum and

nitrogen at higher levels than the (UNS S31803) composition.

Product Range

Specifications: ASTM A/ASME SA213/A249/A269/A312/A358 CL. I to V ASTM A789/A790

Sizes (Seamless): 1/2" NB - 24" NB

Sizes (ERW): 1/2" NB - 24" NB

Sizes (EFW): 6" NB - 100" NB

Wall Thickness available:

Schedule 5S - Schedule XXS (heavier on request)

Other Materials Testing:

NACE MR0175, H2 SERVICE, OXYGEN SERVICE, CRYO SERVICE, etc.

Dimensions:

All Pipes is manufactured and inspected/tested to the relevant standards including ASTM, ASME and API

etc.

| Trade Name | UNS | Duplex Stainless Steel Industry Specifications | Chemical Composition | Min.Tensile (KSI) |

Min.Yield (KSI) |

Elongation % |

| SAF 2205® 22Cr |

UNS S31803 |

ASME SA-182 (F51), SA-240, SA-798, SA-790, SA-815 ASTM A182 (F51),A240, A276, A479, A789, A790, A815, A928, A988 SAE J405 |

C 0.30 max Cr 21.0-23.0 Mn 2.00 max Mo 2.50-3.50 N 0.08-0.20 Ni 4.50-6.50 P 0.030 max S 0.020 max Si 1.00 max |

90 | 65 | 25 |

| SAF 2205® 22Cr |

UNS S32205 | ASME SA-182 (F60), SA-240, SA-798, SA-790, SA-815 ASTM A182 (F60), A240, A276, A479, A480, A798, A790, A815, A928, A988 SAE J405 |

C 0.30 max Cr 22.0-23.0 Mn 2.00 max Mo 3.00-3.50 N 0.14-0.20 Ni 4.50-6.50 P 0.030 max S 0.020 max Si 1.00 max |

95 | 65 | 25 |

2205 is the most widely used duplex (ferritic/austenitic) stainless steel grade. It finds applications

due to both excellent corrosion resistance and high strength. The standard duplex S31803 composition has

over the years been refined by many steel suppliers, and the resulting restricted composition range was

endorsed as UNS S32205 in 1996. Duplex S32205 gives better guaranteed corrosion resistance, but for much

of the Duplex S31803 currently produced also complies with Duplex S32205. 2205 is not generally suitable

for use at temperatures above 300ºC as it suffers from precipitation of brittle micro-constituents, nor

below -50ºC because of its ductile-to-brittle-transition.

"Duplex” is a stainless steel family that is neither fully austenitic, such as 304 stainless, nor

ferritic such as 430 stainless steel. The 2205 duplex stainless steel structure consists of austenite

pools surrounded by a continuous ferrite phase. In the annealed condition, 2205 has approximately 40-50%

ferrite. The 2205 Duplex is mostly referred to as the work horse grade and is the most widely used grade

in the duplex family of stainless steels.

The benefit of a duplex structure is that the favorable qualities of a ferritic alloy are combined with

those of an austenitic alloy that features corrosion resistance and ease of fabrication. Usage of 2205

Duplex stainless steel should be limited to temperatures below 600° F. Extended elevated temperature

exposure can embrittle 2205 stainless.

Grade Specification Comparison of UNS S32205 Duplex Stainless Steel Pipe

Table 4 provides the grade comparison for 2205 stainless steels. The values are a comparison of

functionally similar materials. Exact equivalents may be obtained from the original specifications.

Table 4 - Grade specification comparisons for 2205 grade stainless steels

| Grade | UNS No |

Old British | Euronorm | SwedishSS | JapaneseJIS | ||

| BS | En | No | Name | ||||

| 2205 | S31803 / S32205 | 318S13 | - | 1.4462 | X2CrNiMoN22-5-3 | 2377 | SUS 329J3L |

Possible Alternative Grades of UNS S32750 Duplex Stainless Steel Pipe

Given below is a list of possible alternative grades, which may be chosen in place of 2205.

Table 5 - Grade specification comparisons for 2205 grade stainless steels

| Grade | Reasons for choosing the grade |

| 904L | Better formability is needed, with similar corrosion resistance and lower strength. |

| UR52N+ | High resistance to corrosion is required, e.g. resistance to higher temperature seawater. |

| 6%Mo | Higher corrosion resistance is required, but with lower strength and better formability. |

| 316L | The high corrosion resistance and strength of 2205 are not needed. 316L is lower cost. |

Duplex Applications of UNS S3205 Duplex Stainless Steel Pipe

Chemical processing, transport and storage

Oil and Gas exploration and processing equipment,

Marine and other high chloride environments,

Pulp and paper digesters, liquor tanks and paper machines.

Duplex corrosion Resistance of UNS S32205 Duplex Stainless Steel Pipe

Excellent general corrosion resistance; superior to Grade 316 in most environments. Excellent resistance

to localized corrosion including intergranular, pitting and crevice corrosion; the CPT of 2205 is

generally at least 35ºC. The grade is also resistant to chloride stress corrosion cracking (SCC) at

temperatures of up to about 150ºC. Grade 2205 will often perform well in environments which cause

premature failure of austenitic grades. It has better resistance to sea water then Grade 316.

Duplex Heat Resistance of UNS S32205 Duplex Stainless Steel Pipe

Although 2205 has good high temperature oxidation resistance, this grade - like other duplex stainless

steels - suffers from embrittlement if held for even short times at temperatures above 300ºC. If

embrittled, this can only be rectified by a full solution annealing treatment. Duplex stainless steels

are almost never used above 300ºC.

Duplex Heat Treatment of UNS S32205 Duplex Stainless Steel Pipe Solution treatment (annealing) - heat to

1020ºC-1100ºC and cool rapidly. This grade cannot be hardened by thermal treatment, but does work

harden.

UNS S32205 Duplex Stainless Steel Pipe and Tube Packing

UNS S32205 Duplex Stainless Steel Pipes and Tubes is sleeved into plastic bag

individually, pieces wrapped with water-proof material, bundled with nylon rope. Clear labels are tagged

on the outside of the package for easy identification of the quantity and product I.D. Great care is

taken during operation and transportation. UNS S322205 Duplex Stainless Steel Pipe packing will be

according to international standard in bundles strapped by strips then into containers to avoid any

damage.

Specification

| ASTM Specification |

astm a790 duplex 2205, SA 789 alloy 2205, a790 gr 2205 |

|---|---|

| Standard | JIS, TOCT, GB, AMS, EN, ASTM, AISI, SAE, ASME, DS, NF, DTD, DIN |

|

International Specifications |

ISO 6207, BS3 3074NA15, VdTüV 412 & 434, DIN 17459 |

| UNS S32205 Welded Pipe Size | 5.0 - 1219.2 mm |

| Alloy 2205 Seamless Pipe Size | 4 to 219mm W. T.: 0.5 to 20mm |

| Duplex 2205 EFW Pipe size | 5.0 - 1219.2 mm |

| 2205 duplex stainless steel Pipe Schedule | SCH5, SCH140, SCH80, XS, SCH10, SCH10S, SCH80, XXS, SCH120, SCH60, SCH30, STD, SCH20, SCH40S, SCH160, SCH40 |

| Duplex 2205 Pipe & Tube Outer Diameter | Sizes up to 12” NB, 6.00 mm OD up to 250 mm OD |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| 2205 duplex stainless steel tubing wall thickness | 0.020" –0.220" (special wall thicknesses available) |

| Alloy 2205 Seamless Tube Size | 3.35 mm OD To 101.6 mm OD, 15 NB to 150 NB IN |

| Duplex 2205 Welded Tube Size | 6.35 mm OD To 152 mm OD |

| Finish | BA (Bright & Annealed), Polished, AP (Annealed & Pickled), NO.1, MF, 2B, NO.4, HL, BA, Mirror finish, 8K etc |

| Length | Single Random, Standard & Cut length , Double Random Pipe |

| Form | Duplex 2205 Pipe are available in form of Square, Round, Rectangular, Hollow, Coiled, Hydraulic, Straight Pipes, Pan Cake Coils, “U” Shape etc. |

| End of WERKSTOFF NR. 1.4462 Pipe | Beveled End, Plain End, Screwed ends, Treaded Pipe |

| Type of UNS S32205 Pipe | Duplex 2205 ERW/ Seamless / Welded / EFW / CDW / Fabricated /CEW/ DOM Pipe |

| Application of Duplex 2205 Pipe | Oil Tube, Boiler and Heatexchanger, Gas Tube, Fluid Tube |

| Marking on ASTM A790 Duplex 2205 Pipe | All ASTM A790 Duplex 2205 Pipes are marked as follows: Grade, Standard, Thickness, OD, Heat No. (Or according to the customer’s request.), Length |

| Specialize in |

|

| Value Added Service | Polish (Electro & Commercial) Annealed & Pickled Bending, Draw & Expansion as per required Size & Length, Machining Etc. |

| manufacturing Technique of Duplex 2205 Pipe | hot drawn, Cold drawn, solid solution, bright annealed, hot extruding |

| Test Certificate of Alloy 2205 Pipe and tube |

|

| Our stockyard of UNS S31803 Pipe | Pimpri-Chinchwad, Abu Dhabi, Port-of-Spain, New Delhi, Gimhae-si, Courbevoie, Riyadh, Calgary, Ahmedabad, Ernakulam, Bangalore, Sydney, Muscat, Lagos, Santiago, Karachi, Caracas, India, Montreal, Nagpur,Indore, Kolkata, Mumbai, Noida, Kanpur, Tau, Gurgaon, Ankara, Perth, Bogota, Ludhiana, Tehran, Mexico, Janeiro, Kuwait, Jamshedpur, Gujarat, Vadodara, Melbourne, Chennai, Rajkot, Coimbatore, Ranchi, Hyderabad, Bengaluru, Baroda, London, Ahvaz, Howrah, Dammam, Khobar, Surat, Manama, Thiruvananthapuram, Istanbul, |

| Material Test Certificates (MTC) |

|

| Duplex 2205 Pipe Dimension ANSI/ ASME B36.10, B36.19, B2.1 We can also thread, cut and groove UNS S32205 Pipe to meet your specifications. | |

Equivalent of ASTM A815 DSS Pipe Elbow

|

PIPE STANDARD

|

WERKSTOFF NR.

|

UNS

|

|

Duplex 2205 Pipe

|

1.4462 / 1.4462

|

S31803 / S32205

|

CHEMICAL COMPOSITION

| C | N | P | Si | Mn | Mo | Fe | Cr | S | Ni |

| 1.0 | 0.03 | 0.02 | 2.0 | 3.0 - 3.5 | 22.0 - 23.0 | 0.03 | 4.5 - 6.5 | 0.14 - 0.2 | Bal |

MECHANICAL PROPERTIES

| Pipe Density | Pipe Melting Point | Yield Strength (0.2%Offset) | 2205 Duplex SS Pipe Tensile Strength | Elongation |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi - 80000 , MPa - 550 | Psi - 116000 , MPa - 800 | 15 % |

UNS S32205 Seamless Pipes are supplied according to ANSI/ ASME B36.19.

OD = Duplex 2205 Pipe outside diameter

WT = Duplex 2205 Pipe wall thickness

|

ASTM A790 Duplex 2205 Pipe OD

mm |

Pipe WT

mm |

in.

|

Sch

|

Kg/m

|

|---|---|---|---|---|

|

13.72

|

1.65

|

1/4

|

10S

|

0.50

|

|

13.72

|

2.24

|

1/4

|

40S

|

0.64

|

|

13.72

|

3.02

|

1/4

|

80S

|

0.81

|

|

17.15

|

1.65

|

3/8

|

10S

|

0.64

|

|

17.15

|

2.31

|

3/8

|

40S

|

0.86

|

|

17.15

|

3.20

|

3/8

|

80S

|

1.12

|

|

21.34

|

2.11

|

1/2

|

10S

|

1.02

|

|

21.34

|

2.77

|

1/2

|

40S

|

1.29

|

|

21.34

|

3.73

|

1/2

|

80S

|

1.65

|

|

26.67

|

2.11

|

3/4

|

10S

|

1.30

|

|

26.67

|

2.87

|

3/4

|

40S

|

1.71

|

|

26.67

|

3.91

|

3/4

|

80S

|

2.23

|

|

33.40

|

2.77

|

1

|

10S

|

2.13

|

|

33.40

|

3.38

|

1

|

40S

|

2.54

|

|

33.40

|

4.55

|

1

|

80S

|

3.29

|

|

33.40

|

6.352)

|

1

|

160

|

4.30

|

|

42.16

|

2.77

|

1¼

|

10S

|

2.73

|

|

42.16

|

3.56

|

1¼

|

40S

|

3.44

|

|

42.16

|

4.85

|

1¼

|

80S

|

4.53

|

|

42.16

|

6.352)

|

1¼

|

160

|

5.69

|

|

48.26

|

2.77

|

1½

|

10S

|

3.16

|

|

48.26

|

3.68

|

1½

|

40S

|

4.11

|

|

48.26

|

5.08

|

1½

|

80S

|

5.49

|

|

60.33

|

2.77

|

2

|

10S

|

3.99

|

|

60.33

|

3.91

|

2

|

40S

|

5.52

|

|

60.33

|

5.54

|

2

|

80S

|

7.60

|

|

60.33

|

8.742)

|

2

|

160

|

11.29

|

|

73.03

|

3.05

|

2½

|

10S

|

5.35

|

|

73.03

|

5.16

|

2½

|

40S

|

8.77

|

|

73.03

|

7.01

|

2½

|

80S

|

11.59

|

|

88.90

|

3.05

|

3

|

10S

|

6.56

|

|

88.90

|

5.49

|

3

|

40S

|

11.47

|

|

88.90

|

7.62

|

3

|

80S

|

15.51

|

|

88.90

|

11.132)

|

3

|

160

|

21.67

|

|

101.60

|

3.05

|

3½

|

10S

|

7.53

|

|

101.60

|

5.74

|

3½

|

40S

|

13.78

|

|

101.60

|

8.08

|

3½

|

80S

|

18.92

|

|

114.30

|

3.05

|

4

|

10S

|

8.50

|

|

114.30

|

6.02

|

4

|

40S

|

16.32

|

|

114.30

|

8.56

|

4

|

80S

|

22.67

|

|

114.30

|

13.492)

|

4

|

160

|

34.05

|

|

141.30

|

6.55

|

5

|

40S

|

22.10

|

|

141.30

|

9.53

|

5

|

80S

|

31.44

|

|

141.30

|

15.882)

|

5

|

160

|

49.87

|

|

168.28

|

3.4

|

6

|

10S

|

14.04

|

|

168.28

|

7.11

|

6

|

40S

|

28.69

|

|

168.28

|

10.97

|

6

|

80S

|

43.21

|

|

168.28

|

14.27

|

6

|

120

|

54.75

|

|

168.28

|

18.262)

|

6

|

160

|

68.59

|

|

219.08

|

8.18

|

8

|

40S

|

43.20

|

|

219.08

|

12.7

|

8

|

80S

|

65.63

|

|

219.08

|

18.23

|

8

|

120

|

91.30

|

|

219.08

|

23.012)

|

8

|

160

|

112.97

|

General characteristics

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2205 | 1.4462 | 2205 | S32205 | 35 | 20 | 500 | D | 0.02 | 22.4 | 5.7 | 3.1 | 0.17 |

| 2507 | 1.4410 | 2507 | S32750 | 43 | 20 | 550 | D | 0.02 | 25.0 | 7.0 | 4.0 | 0.27 |

| 2205 stainless steel grades | Industry Specifications | UNS |

Duplex 2205 2205 (EN 1.4462/UNS S32205 & S31803) |

• Cargo tanks in chemical tankers • Pulp and paper industry applications such as digesters and process tanks • Oil and gas industry, typically tubular products, flanges, fittings and valves • Structural components in bridges |

• Cold rolled coil and sheet • Hot rolled coil and sheet • Quarto plate • Bar • Wire rod • Semi-finished (bloom, billet, ingot & slab) |

| Duplex 2507 2507 (EN 1.4410/UNS S32750) A super duplex product with higher corrosion resistance and mechanical strength than Forta DX 2205. Often used in extremely corrosive environments. |

• Desalination plants • Industrial piping • Scrubbers • Oil and gas industry, typically tubular products, flanges,fittings and valves • Deep-sea pipelines |

• Cold rolled coil and sheet • Hot rolled coil and sheet • Quarto plate • Bar • Wire rod • Semi-finished (bloom, billet, ingot & slab) |

| Duplex 32760 100 (EN 1.4501/UNS S32760) A super duplex product with higher corrosion resistance and mechanical strength than Forta DX 2205. Often used in extremely corrosive environments. |

• Desalination plants • Industrial piping • Scrubbers • Oil and gas industry, typically tubular products, flanges, fittings and valves • Deep-sea pipelines |

• Cold rolled coil and sheet • Hot rolled coil and sheet • Quarto plate • Bar • Wire rod • Semi-finished (bloom, billet, ingot & slab) |

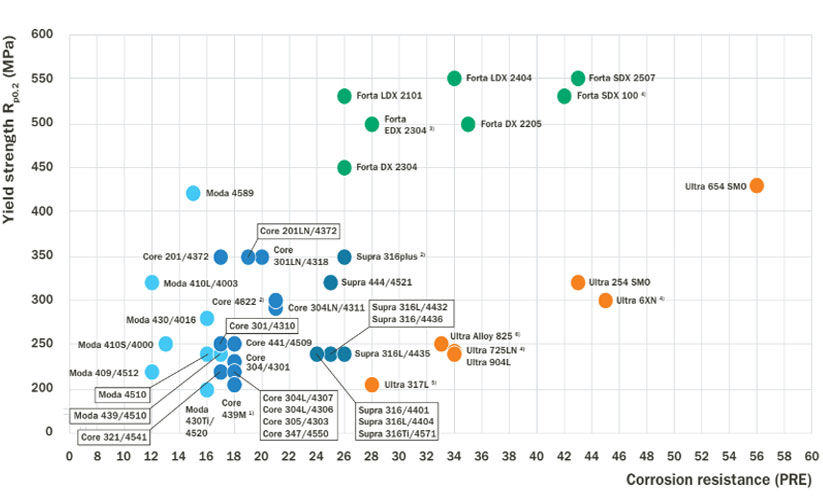

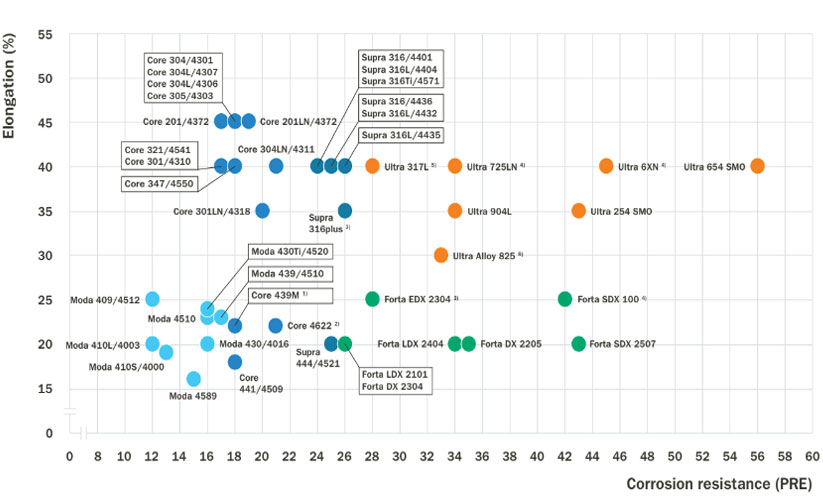

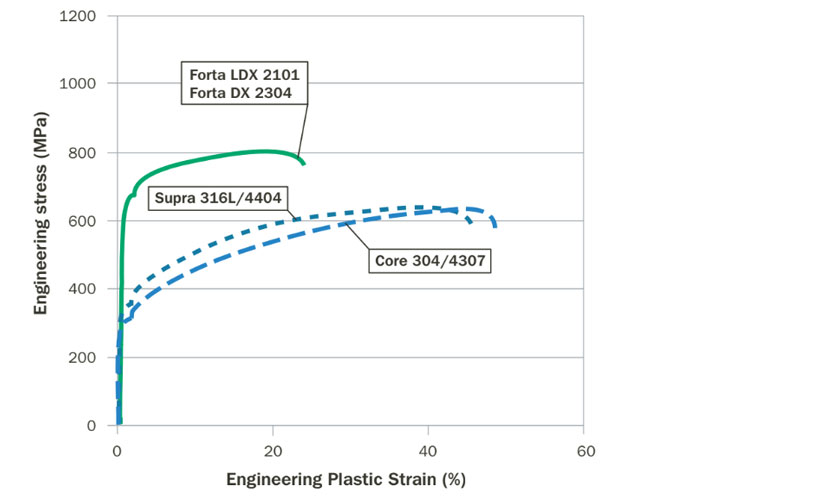

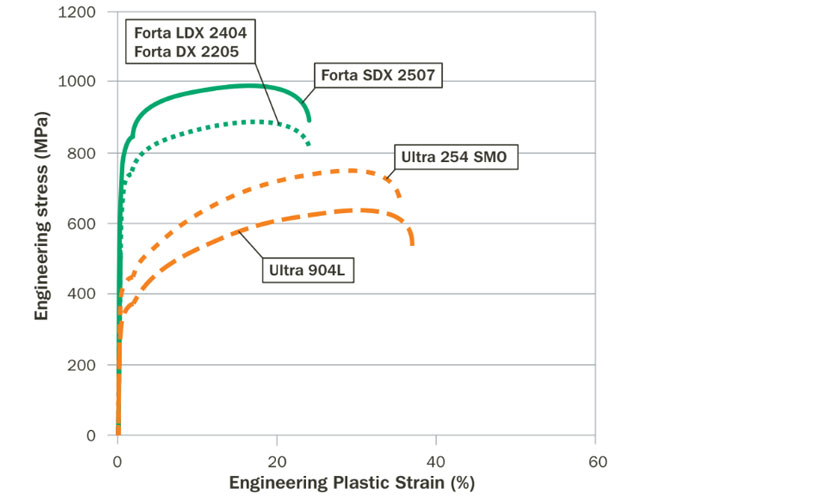

Performance

Elongation vs. corrosion resistance.

Elongation vs. Corrosion resistance

Strength vs. Corrosion resistance

Elongation vs. Corrosion resistance

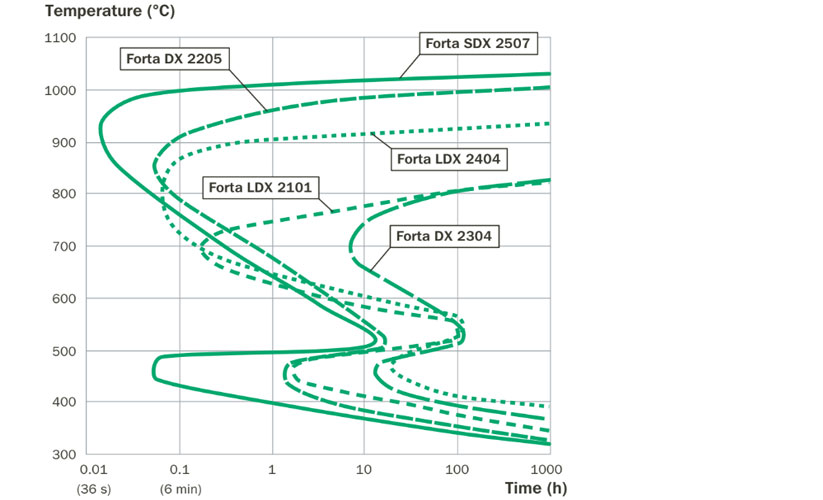

Duplex stainless steels, known for their high chromium content, provide excellent corrosion resistance, particularly in uniform corrosion environments with rates below 0.1 mm/year. Forta DX 2205 shows superior resistance to chloride-contaminated sulfuric acid compared to traditional stainless steels like Supra 316L/4404, approaching the performance of Ultra 904L. In dilute hydrochloric acid, Forta SDX 2507 and similar high-alloyed duplex steels are suitable, though localized corrosion risks exist around crevices even within safe usage limits.

PRE values for Forta Duplex grades and some austenitic grades

Steel designations |

PRE |

|||

| name | EN | ASTM Type |

UNS | |

| 2205 | 1.4462 | 2205 | S32205 | 35 |

| 2507 | 1.4410 | 2507 | S32750 | 43 |

Results from stress corrosion cracking immersion tests in chloride solutions

| name | ASTM G123 | ASTM G36 | ||

| 25% NaCl, pH 1.5, 106°C (b.p.), 1,000 h | 40% CaCl2, 100°C, 500 h | 45% MgCl2, 155°C (b.p.), 24 h | ||

| U-bend samples | 4-PB samples (90% of Rp0.2) | U-bend samples | ||

| 2205 | No SCC | No SCC | SCC | |

| 2507 | No SCC | No SCC | SCC | |

Mechanical properties according to EN 10088 and EN 10028

| EN | ASTM | Product form | Yield strength | Tensile | Elongation | Elongation | |

| name | UNS | Rp0.2[MPa] | strength | A[%] | A80[%] | ||

| Rm[MPa] | |||||||

| 2205 | 1.4462 | S32205 | Cold rolled coil (C) | 500 | 700–950 | 20 | 20 |

| Hot rolled coil (H) | 460 | 700–950 | 25 | 25 | |||

| Quarto plate (P) | 460 | 640–840 | 25 | 25 | |||

| Wire rod 1) | 510 | 750 | 35 | – | |||

| Bar | 450 | 650–880 | 25 | – | |||

| 2507 | 1.4410 | S32750 | Cold rolled coil (C) | 550 | 750–1000 | 20 | 20 |

| Hot rolled coil (H) | 530 | 750–1000 | 20 | 20 | |||

| Quarto plate (P) | 530 | 730–930 | 20 | 20 | |||

| Bar | 530 | 730–930 | 25 | – | |||

| 1.4510 | S32760 | Cold rolled coil (C) | 550 | 750–1000 | 20 | 20 | |

| Hot rolled coil (H) | 530 | 750–1000 | 25 | 25 | |||

| Quarto plate (P) | 530 | 730–930 | 25 | 25 |

Mechanical properties according to ASTM A240

| EN | ASTM | Product form | Yield | Yield | Tensile | Tensile | Elongation | |

| name | UNS | strength | strength | strength | strength | A50[%] | ||

| Rp0.2[MPa] | Rp0.2 [ksi] | Rm [MPa] | Rm [ksi] | |||||

| 2205 | 1.4462 | S32205 | Plate, sheet and strip | 450 | 65 | 655 | 95 | 25 |

| Wire rod 1) | 510 | 74 | 752 | 109 | – | |||

| 2507 | 1.4410 | S32750 | Plate, sheet and strip | 550 | 80 | 795 | 116 | 15 |

| 100 | 1.4501 | S32760 | Plate, sheet and strip | 550 | 80 | 750 | 108 | 25 |

Mechanical properties at elevated temperatures, minimum yield strength according to EN 10028-7

| name | Strength | 100°C | 150°C | 200°C | 250°C | |

| 2205 | Yield strength | Rp0.2 [MPa] | 360 | 335 | 315 | 300 |

| Tensile strength | Rm [MPa] | 590 | 570 | 550 | 540 | |

| 2507 | Tensile strength | Rm [MPa] | 680 | 660 | 640 | 630 |

Physical properties

Metric values according to EN 10088-1

| name | EN | ASTM Type | UNS | Density [kg/dm3] | Modulus of elasticity at 20°C [GPa] | Coefficient of thermal expansion 20–100°C [10-6/K] | Thermal conductivity at 20°C [W/(m x K)] | Thermal capacity at 20°C [J/(kg x K)] | Electrical resistivity at 20°C [Ω x mm2/m] |

| 2205 | 1.4462 | 2205 | S32205 | 7.8 | 200 | 13.0 | 15 | 500 | 0.8 |

| 2507 | 1.4410 | 2507 | S32750 | 7.8 | 200 | 13.0 | 15 | 500 | 0.8 |

| 100 | 1.4410 | - | S32760 | 7.8 | 200 | 13.0 | 15 | 500 | 0.8 |

Imperial values converted from Table 10

| name | Density [lbm/in3] | Modulus of elasticity [psi] | Coefficient of thermal expansion 68–212°F [μin / (in x °F)] | Thermal conductivity [Btu/(hr x ft x °F)] | Thermal capacity [Btu/(lbm x °F)] | Electrical resistivity [μΩ x in] |

| 2205 | 0.282 | 29 x 106 | 7.2 | 8.7 | 0.119 | 31.50 |

| 2507 | 0.282 | 29 x 106 | 7.2 | 8.7 | 0.119 | 31.50 |

Fabrication

Duplex stainless steel is suitable for all forming processes used for stainless steel. The high yield strength compared to austenitic and ferritic stainless steel can however give differences in forming behavior. Depending on the chosen forming technique there could be consequences, such as increased springback. This point is particularly relevant to the forming of any high strength steel. Moreover, an excellent interplay between high yield strength, work hardening rate and elongation promote the duplex grades for light weight and cost-efficient applications with complex shapes. The impact of the high strength varies for different forming techniques. Common for all is that the estimated forming forces will be higher than for the corresponding austenitic and ferritic stainless steel grades. This effect will usually be lower than expected from just the increase in strength since the choice of duplex stainless steel is often associated with gauge reduction. It is important to consider that duplex stainless steel may also be more demanding on the tools and on the lubricant. This should also be noted when looking to down gauge.

Welding consumables

| name | EN | ASTM Type | UNS | Consumable ISO designation |

| 2507 | 1.4462 | 2205 | S32205 | 22 9 3 NL |

| 2507 | 1.4410 | 2507 | S32750 | 25 9 4 NL |

Product

Quick contact

Get Solution

Organically grow the holistic world view of disruptive innovation via workplace diversity

Contact Us