- Chintamani Stainless Inc, 132, T.P. Streets, 6th Kumbharwada Lane, Mumbai- 400004, India

- Trophy Winning

- Ceritified ( ISO 9005-2010 )

Super Duplex Fastener

Chintamani Stainless Inc is a well-established venture that is manufacturing, exporting and supplying Super Duplex Steel Fasteners from the last many years. Providing the best and innovative product to the customer is our first priority. We offer our product to both national and international customers. To design a global standard product we acquire the finest quality of raw material for the manufacturing and also equipped the most advanced technology and tools to bring out accuracy and end finish in the product. To keep in mind customer’s requirement and needs we cater our product in custom made shapes, size, length, and thickness at quite a reasonable rate.

Super Duplex Steel Fasteners are mixed microstructure of ferrite and austenite that are used in those applications where exceptional corrosion resistance and strength is required. These include molybdenum, nitrogen and chromium content that provides great resistance to crevice corrosion and chloride pitting attacks. These are generally used in aggressive environments such as warm chlorinated water, chloride containing media. These grade of fastener ensure good resistance to erosion and abrasion. Furthermore, they offer superior resistance to uniform and local corrosion at soaring temperatures. These fasteners offer superior services in severe atmospheric conditions such as marine and offshore applications. These range of fasteners features low thermal expansion and fatigue resistance in high energy absorption. In addition to it has good mechanical strength and ensures good weldability.

Super duplex 2507 bolts offer a variety of valuable features and applications. These super-strong bolts are designed to withstand high pressure and temperature, making them ideal for environments where these factors are a concern. They also have higher corrosion resistance, making them perfect for operations where contact with seawater or other corrosive substances is likely. Furthermore, super duplex 2507 bolts can be used in the most challenging environments due to their superior strength, making them perfect candidates for offshore and oilfield operations. All in all, super duplex 2507 bolts provide an excellent combination of strength, durability and corrosion resistance, perfect for any function that demands a dependably robust fastener.

Super duplex 1.4410 fasteners are becoming increasingly popular as a fastening solution due to their enormous strength and excellent corrosion resistance. These fasteners are available in various shapes and sizes, including screws, bolts, nuts, washers, rivets and anchors. They have high fatigue strength and superb hot corrosion resistance properties. Furthermore, super duplex 1.4410 fasteners have super-austenitic stainless steel characteristics, making them an ideal choice when exposed to hostile environments. As a result of their increased popularity, they are widely used in various industries such as mining and oil & gas exploration and production.

Specification

| Specifications of Super Duplex 2507 Fasteners | ASTM / ASME F53, A479 / SA479 |

| Standard of Super Duplex 2507 Fasteners | DIN, ASTM, BS and all International Standards |

| Length of Super Duplex 2507 Fasteners | 3 mm to 200 mm |

| Super Duplex 2507 Nuts Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Super Duplex 2507 Bolt / Screw Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Super Duplex 2507 Machine Screws Size | M1.6 - M12 |

| Super Duplex 2507 Washers Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Super Duplex Steel Grades | Super Duplex Steel UNS S32750 |

| Super Duplex 2507 Fasteners Type | Socket Head Cap Screw, Wing Screw, T-Head Bolts, Foundation Bolts,Screw, Studs, Socket Screw, Hex Set Screw, Cap Screw, Machine Screw, Wing Screw, Spring Washers, Eye Bolt,Structural Bolts, Bolts, Nuts, Sockets, Screws, Allen Cap screw, Washers, Studs, Marine Anchors, Anchors, Hexagon Nut,U- Bolts, Anchor Bolt, Nut, Hex Coupling Nut, Hex Nut, Square Nut, Hex Domed Cap Nuts, Hex Head Bolts, Stud Bolts, Socket Hexagon Head Screw, Pan Head Screw, Mushroom Head Square Neck Bolts, J Bolts |

CHEMICAL COMPOSITION

|

Element

|

Content (%)

|

|---|---|

|

Chromium, Cr

|

24 – 26

|

|

Nickel, Ni

|

6 – 8

|

|

Molybdenum, Mo

|

3 – 5

|

|

Manganese, Mn

|

1.20 max

|

|

Silicon, Si

|

0.80 max

|

|

Copper, Cu

|

0.50 max

|

|

Nitrogen, N

|

0.24 – 0.32

|

|

Phosphorous, P

|

0.035 max

|

|

Carbon, C

|

0.030 max

|

|

Sulfur, S

|

0.020 max

|

|

Iron, Fe

|

Balance

|

MECHANICAL PROPERTIES

|

Grade

|

Tensile Strength

(MPa) min |

Yield Strength

0.2% Proof (MPa) min |

Elongation

(% in 50mm) |

Hardness

Rockwell C (HR C) |

|---|---|---|---|---|

|

UNS-S 32750

|

795

|

550

|

15

|

32max

|

ASTM F53 Super Duplex Steel 2507 Fasteners Equivalent Grade

|

Alloy

|

Common Name

|

Related Specification

|

||

|---|---|---|---|---|

|

European

|

UNS

|

ASTM/ASME

|

||

|

Alloy 2507

|

SAF 2507 ®

|

1.4410

|

UNS S32750

|

A479 / SA479 / F53

|

Super Duplex Stud Bolts Application

- Petrochemicals

- Aircraft Exhaust Manifolds

- Off-Shore Oil Drilling Companies

- Sea Water Equipment

- Pharmaceuticals

- Power Generation

General characteristics

|

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

|

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2507 | 1.4410 | 2507 | S32750 | 43 | 20 | 550 | D | 0.02 | 25.0 | 7.0 | 4.0 | 0.27 |

| 2205 stainless steel grades | Industry Specifications | UNS |

| Duplex 2507 2507 (EN 1.4410/UNS S32750) A super duplex product with higher corrosion resistance and mechanical strength than Forta DX 2205. Often used in extremely corrosive environments. |

• Desalination plants • Industrial piping • Scrubbers • Oil and gas industry, typically tubular products, flanges,fittings and valves • Deep-sea pipelines |

• Cold rolled coil and sheet • Hot rolled coil and sheet • Quarto plate • Bar • Wire rod • Semi-finished (bloom, billet, ingot & slab) |

| Duplex 32760 100 (EN 1.4501/UNS S32760) A super duplex product with higher corrosion resistance and mechanical strength than Forta DX 2205. Often used in extremely corrosive environments. |

• Desalination plants • Industrial piping • Scrubbers • Oil and gas industry, typically tubular products, flanges, fittings and valves • Deep-sea pipelines |

• Cold rolled coil and sheet • Hot rolled coil and sheet • Quarto plate • Bar • Wire rod • Semi-finished (bloom, billet, ingot & slab) |

Performance

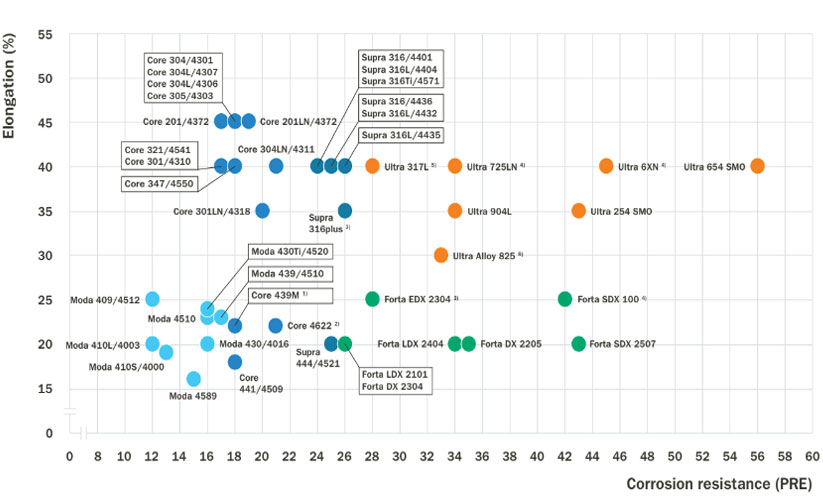

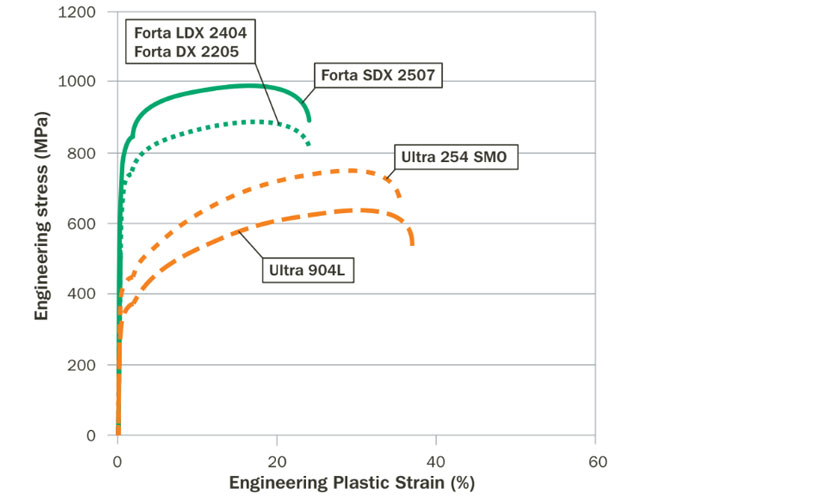

Elongation vs. corrosion resistance.

Elongation vs. Corrosion resistance

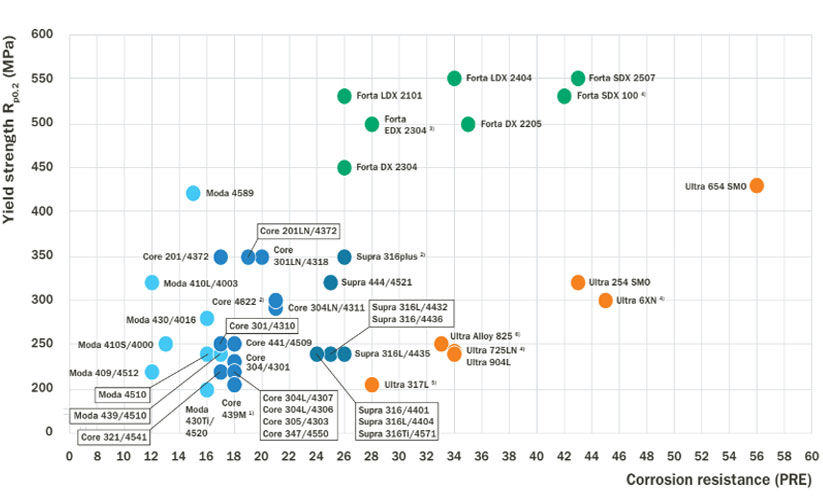

Strength vs. Corrosion resistance

Elongation vs. Corrosion resistance

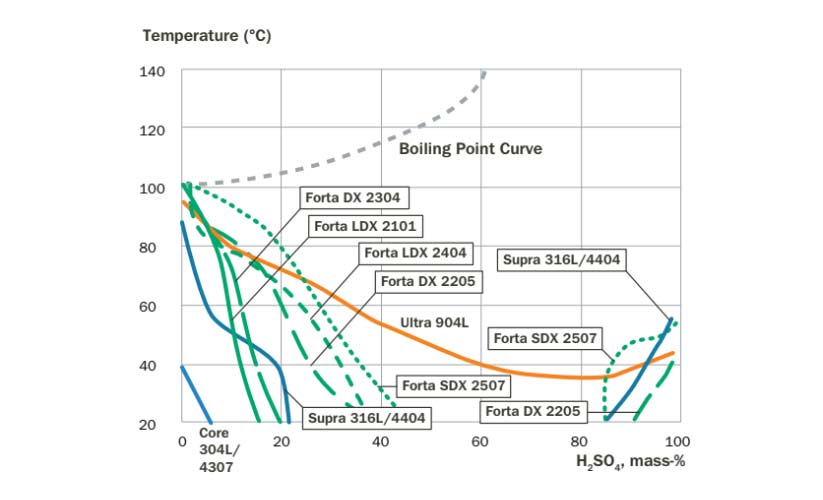

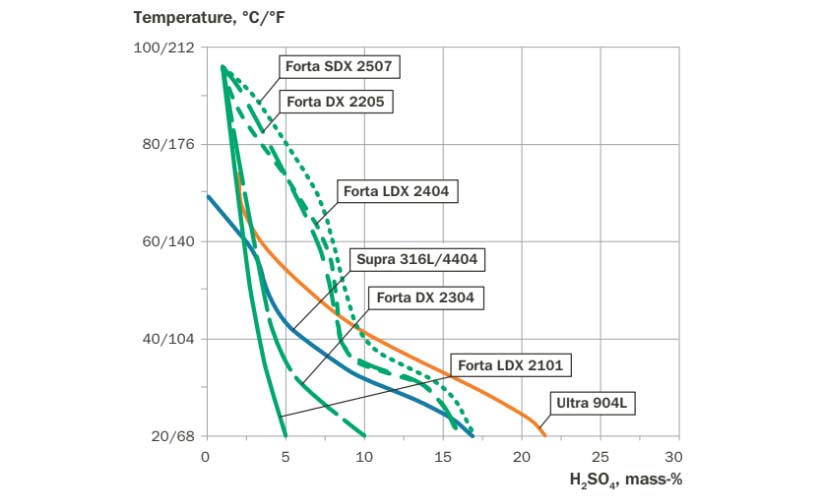

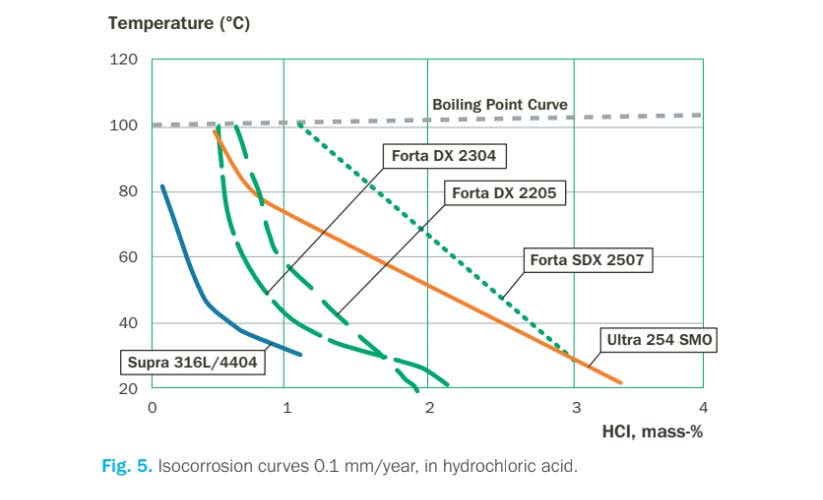

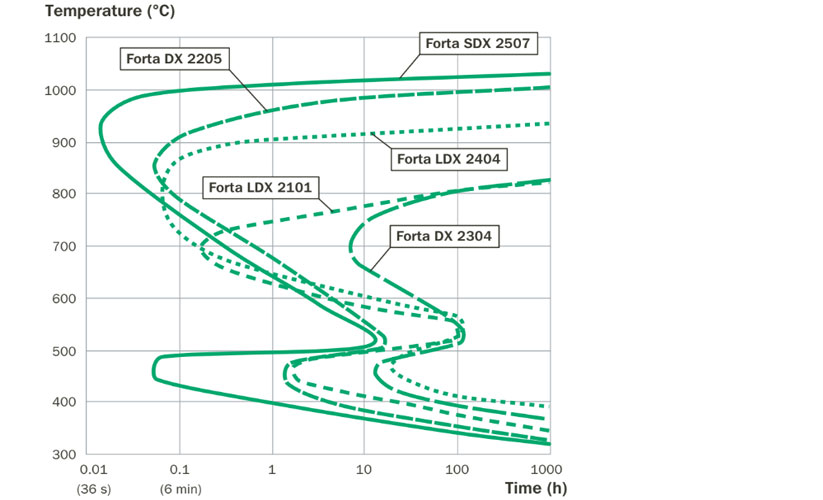

Duplex stainless steels, known for their high chromium content, provide excellent corrosion resistance, particularly in uniform corrosion environments with rates below 0.1 mm/year. Forta DX 2205 shows superior resistance to chloride-contaminated sulfuric acid compared to traditional stainless steels like Supra 316L/4404, approaching the performance of Ultra 904L. In dilute hydrochloric acid, Forta SDX 2507 and similar high-alloyed duplex steels are suitable, though localized corrosion risks exist around crevices even within safe usage limits.

Corrosion resistance

- Uniform Corrosion: Due to high chromium content, these steels resist uniform corrosion well, typically less than 0.1 mm/year.

- Sulfuric Acid: DX 2205 shows superior resistance in sulfuric acid contaminated by chloride ions compared to Supra 316L/4404.

- Hydrochloric Acid: SDX 2507 and DX 2205 can be used in dilute hydrochloric acid, with potential risks of localized corrosion in crevices.

- Nitric Acid: LDX 2101 and DX 2304, with their high chromium content and low molybdenum, are suitable for environments where resistance to strongly oxidizing nitric acid is needed.

PRE values for Forta Duplex grades and some austenitic grades

|

Steel designations |

PRE |

|||

| name | EN | ASTM Type |

UNS | |

| 2205 | 1.4462 | 2205 | S32205 | 35 |

| 2507 | 1.4410 | 2507 | S32750 | 43 |

Results from stress corrosion cracking immersion tests in chloride solutions

| name | ASTM G123 | ASTM G36 | ||

| 25% NaCl, pH 1.5, 106°C (b.p.), 1,000 h | 40% CaCl2, 100°C, 500 h | 45% MgCl2, 155°C (b.p.), 24 h | ||

| U-bend samples | 4-PB samples (90% of Rp0.2) | U-bend samples | ||

| 2205 | No SCC | No SCC | SCC | |

| 2507 | No SCC | No SCC | SCC | |

Mechanical properties according to EN 10088 and EN 10028

| EN | ASTM | Product form | Yield strength | Tensile | Elongation | Elongation | |

| name | UNS | Rp0.2[MPa] | strength | A[%] | A80[%] | ||

| Rm[MPa] | |||||||

| 2507 | 1.4410 | S32750 | Cold rolled coil (C) | 550 | 750–1000 | 20 | 20 |

| Hot rolled coil (H) | 530 | 750–1000 | 20 | 20 | |||

| Quarto plate (P) | 530 | 730–930 | 20 | 20 | |||

| Bar | 530 | 730–930 | 25 | – | |||

| 1.4510 | S32760 | Cold rolled coil (C) | 550 | 750–1000 | 20 | 20 | |

| Hot rolled coil (H) | 530 | 750–1000 | 25 | 25 | |||

| Quarto plate (P) | 530 | 730–930 | 25 | 25 |

Mechanical properties according to ASTM A240

| EN | ASTM | Product form | Yield | Yield | Tensile | Tensile | Elongation | |

| name | UNS | strength | strength | strength | strength | A50[%] | ||

| Rp0.2[MPa] | Rp0.2 [ksi] | Rm [MPa] | Rm [ksi] | |||||

| 2507 | 1.4410 | S32750 | Plate, sheet and strip | 550 | 80 | 795 | 116 | 15 |

| 100 | 1.4501 | S32760 | Plate, sheet and strip | 550 | 80 | 750 | 108 | 25 |

Mechanical properties at elevated temperatures, minimum yield strength according to EN 10028-7

| name | Strength | 100°C | 150°C | 200°C | 250°C | |

| 2507 | Tensile strength | Rm [MPa] | 680 | 660 | 640 | 630 |

Physical properties

Metric values according to EN 10088-1

| name | EN | ASTM Type | UNS | Density [kg/dm3] | Modulus of elasticity at 20°C [GPa] | Coefficient of thermal expansion 20–100°C [10-6/K] | Thermal conductivity at 20°C [W/(m x K)] | Thermal capacity at 20°C [J/(kg x K)] | Electrical resistivity at 20°C [Ω x mm2/m] |

| 2507 | 1.4410 | 2507 | S32750 | 7.8 | 200 | 13.0 | 15 | 500 | 0.8 |

| 100 | 1.4410 | - | S32760 | 7.8 | 200 | 13.0 | 15 | 500 | 0.8 |

Imperial values converted from Table 10

| name | Density [lbm/in3] | Modulus of elasticity [psi] | Coefficient of thermal expansion 68–212°F [μin / (in x °F)] | Thermal conductivity [Btu/(hr x ft x °F)] | Thermal capacity [Btu/(lbm x °F)] | Electrical resistivity [μΩ x in] |

| 2507 | 0.282 | 29 x 106 | 7.2 | 8.7 | 0.119 | 31.50 |

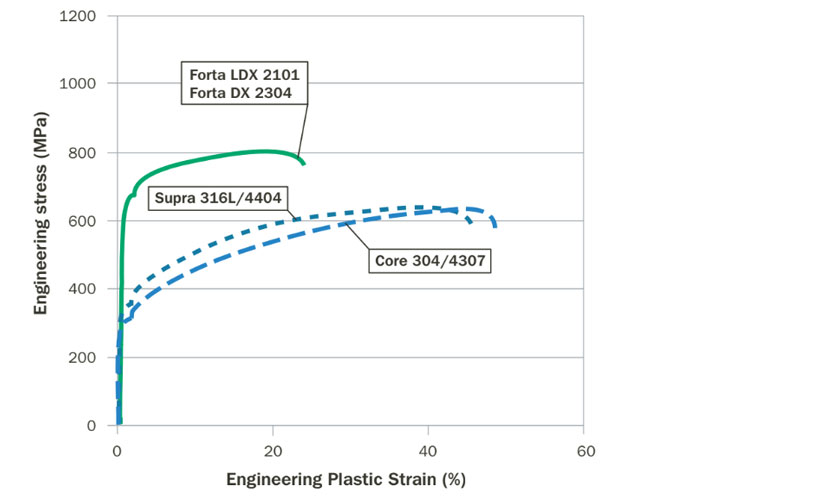

Fabrication

Duplex stainless steel is suitable for all forming processes used for stainless steel. The high yield strength compared to austenitic and ferritic stainless steel can however give differences in forming behavior. Depending on the chosen forming technique there could be consequences, such as increased springback. This point is particularly relevant to the forming of any high strength steel. Moreover, an excellent interplay between high yield strength, work hardening rate and elongation promote the duplex grades for light weight and cost-efficient applications with complex shapes. The impact of the high strength varies for different forming techniques. Common for all is that the estimated forming forces will be higher than for the corresponding austenitic and ferritic stainless steel grades. This effect will usually be lower than expected from just the increase in strength since the choice of duplex stainless steel is often associated with gauge reduction. It is important to consider that duplex stainless steel may also be more demanding on the tools and on the lubricant. This should also be noted when looking to down gauge.

Welding consumables

| name | EN | ASTM Type | UNS | Consumable ISO designation |

| 2507 | 1.4410 | 2507 | S32750 | 25 9 4 NL |

General characteristics

|

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

|

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2507 | 1.4410 | 2507 | S32750 | 43 | 20 | 550 | D | 0.02 | 25.0 | 7.0 | 4.0 | 0.27 |

Product

Quick contact

Get Solution

Organically grow the holistic world view of disruptive innovation via workplace diversity

Contact Us