- Chintamani Stainless Inc, 132, T.P. Streets, 6th Kumbharwada Lane, Mumbai- 400004, India

- Trophy Winning

- Ceritified ( ISO 9005-2010 )

Super Duplex Fittings

Chintamani Stainless Incs is a Duplex Fittings Manufacturer that produces all kinds of pipe

fittings in the duplex steel grade. We accommodate custom order and provide customers

with the best quality products. There are different grades and standards of duplex and

the pipes have different dimensions. The ANSI B16.9 Duplex Steel Pipe Fittings range

from small to 48 inches diameter pipes and fittings. These highly corrosion resistant

components and are used in different applications that need to have corrosion resistant

material. The Duplex Fittings are strong and durable so that they could be used in sea

water, marine, food processing and chemical industries. The use of Duplex Stainless

Steel Elbow is necessary to change the direction of the piping usually in either 90

degrees or 45 degrees angles. There are different grades such as the ASME SA815 Duplex

Pipe And Fittings which are super strong and can be used in high temperature

applications. There are different types of fittings in the duplex grade as well.

Couplings, nipples, unions, elbows and bend are some of them. We manufacture all kinds

of pipe fittings. The Duplex Steel Pipe End Cap is used to terminate a connection.

Threaded caps are used to fit threaded pipes and for permanent closures, the caps are

welded. The reducers are used for alternating pipe sizes. The Duplex Steel Reducer

Dimension differs from standard to standard. We are happy to provide with a full

catalogue of our duplex pipe fittings upon inquiry.

Super Duplex Grade material is used to make Super Duplex Fittings. One of the top manufacturers and

suppliers of Super duplex 2507 pipe fittings in a range of sizes and forms is Chintamani Stainless Incs. Although the

2507 grade of super duplex is the most commonly utilised, other grades are also utilised in the

production of other fittings, including ASTM A815 UNS S32760 Fittings. For these fittings, there are

various schedules, pressure classes, and standards. Because of its austenitic and ferritic

characteristics, the super duplex material is robust and resistant to corrosion. Moreover, the Super

Duplex stainless steel fittings can function at high temperatures and are resistant to high

temperatures.

The industries that use the technology include the petrochemical and petroleum products, power

generation, oil drilling, and the chemical, pharmaceutical, and medical fields. Alloy 2507 pipe fittings

come in a variety of forms, including bends, elbows, couplings, unions, and many more. Every fitting has

a function to fulfil. While the other end caps are used to join various fittings or pipes together, the

end caps are used to close a pipe line. The diameters of the SAF 2507 Fittings also vary.The customary

measurements go from ½ inch to 48 inches. Although the material is more expensive than regular stainless

steel, it is also more durable and economical over time. Applications requiring high levels of heat

resistance, oxidation resistance, and corrosion resistance can employ the Super Duplex s32750 Fittings.

The high pressure applications such as boilers, condensers and heat exchangers also use these fitting. Please contact us for more information and pricing of the different fittings such as the Super Duplex elbow and the prices.

Specification

| Specifications | ASTM A815 and ASME SA815 |

|---|---|

| Size Range | Welded Fittings: 1/2 – 48 Inch Seamless Fittings: 1/2 – 10 Inch |

| Type | DN15 to DN1200 |

| Connection | Welding |

| Radius of bending | 10D, 2D, 3D, 1D, 8D, 5D, 6D, |

| Manufacturing process | Forge, Cast, Press, Push |

| Thickness | SCH80, XS, STD, XXS, SCH100, SCH30, SCH20, SCH160, SCH60, SCH40, SCH120, SCH140, SCH10 |

| Pressure Ratings | 2000#, 6000#, 150#, 3000#, 9000# |

| End Connections |

Socket weld / Threaded |

| Duplex 2205 Pipe Fittings manufacturer | 90º Elbows, Tee, Pipe Cap, 45º Elbows, Crosses, Stub End, Pipe Bend, Reducers |

| Dimensions | ASME B16.28, ASME/ANSI B16.9, BS4504, MSS-SP-43, BS1560, BS10 |

| Elbows | Angle = 2D, 3D, 1.5D, 5D, 2.5D, 1D, 6D, 4D, 7D-40D Standard = JISB2312, 22.5 deg, DIN2605, JISB2313, 30deg, ASME B16.9, MSS SP-75, 180 deg, 45 deg, JISB2311 BS, 90 deg, GB ISO |

| Test Certificates | Raw Materials Certificate EN 10204/3.1B Third Party Inspection Report, etc |

| Origin & Mills | USA, Japanese, Indian, Korean, European, Russian, Ukraine, |

SUPER DUPLEX STEEL UNS S32760 PIPES FITTING EQUIVALENT GRADE

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex UNS S32750 | 1.4410 | S32750 |

| Super Duplex UNS S32760 | 1.4410 | S32760 |

Duplex UNS S32507 Pipe Fittings Dimensions Chart According To ASME B16.9

| NPS (Normal Pipe Size) | O.D. (Outside Daimeter) | Elbow 90 Deg | Elbow 45 Deg | Return Elbow 180 Deg | ||||

|---|---|---|---|---|---|---|---|---|

| (inch) | Long Radius Elbow | Short Radius | Long Radius Elbow | Long Radius Elbow | ||||

| (millimeter/ MM) | (inch./ Inches) | Center to Face (Inches) |

Center to Face (Inches) |

Center to Face (Inches) |

Radius (Inches) |

Center to Center (Inches) |

Back to face (Inches) |

|

| 1/2 | 21.3 | 0.840 | 1 1/2 | – | 5/8 | 2 | 1 7/8 | |

| 3/4 | 26.7 | 1.050 | 1 1/8 | – | 7/16 | 2 1/4 | 1 11/16 | |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 | 7/8 | 3 | 2 3/16 | |

| 1 1/4 | 42.2 | 1.660 | 1 7/8 | 1 1/4 | 1 | 3 3/4 | 2 3/4 | |

| 1 1/2 | 48.3 | 1.900 | 2 1/4 | 1 1/2 | 1 1/8 | 3 | 4 1/2 | 3 1/4 |

| 2 | 60.3 | 2.375 | 3 | 2 | 1 3/8 | 4 | 6 | 4 3/16 |

| 2 1/2 | 73.0 | 2.875 | 3 3/4 | 2 1/2 | 1 3/4 | 5 | 7 1/2 | 5 3/16 |

| 3 | 88.9 | 3.500 | 4 1/2 | 3 | 2 | 6 | 9 | 6 1/4 |

| 3 1/2 | 101.6 | 4.000 | 5 1/4 | 3 1/2 | 2 1/4 | 7 | 10 1/2 | 7 1/4 |

| 4 | 114.3 | 4.500 | 6 | 4 | 2 1/2 | 8 | 12 | 8 1/4 |

| 5 | 141.3 | 5.563 | 7 1/2 | 5 | 3 1/8 | 10 | 15 | 10 5/16 |

| 6 | 168.3 | 6.625 | 9 | 6 | 3 3/4 | 12 | 18 | 12 5/16 |

| 8 | 219.1 | 8.625 | 12 | 8 | 5 | 12 | 24 | 16 5/16 |

| 10 | 273.1 | 10.750 | 15 | 10 | 6 1/4 | 15 | 30 | 20 3/8 |

| 12 | 323.9 | 12.750 | 18 | 12 | 7 1/2 | 18 | 36 | 24 3/8 |

| NPS (Normal Pipe Size) | O.D. (Outside Daimeter) | ASME B16.9 Pipe End Cap | ASME B16.9 Straight Tee | ASME B16.9 Straight Cross | ASME B16.9 Long And Short Stub Ends | |||

|---|---|---|---|---|---|---|---|---|

| (inch./ Inches) | (millimeter/ MM) | (Inches) | Length (Inches) |

Center to End (Inches) |

Center to End (Inches) |

Lap Diameter (Inches) |

Long Length (Inches) |

Short Length (Inches) |

| 1/2 | 21.3 | 0.840 | 1 | 1 | – | 1 3/8 | 3 | 2 |

| 3/4 | 26.7 | 1.050 | 1 | 1 1/8 | – | 1 11/16 | 3 | 2 |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 1/2 | 1 1/2 | 2 | 4 | 2 |

| 1 1/4 | 42.2 | 1.660 | 1 1/2 | 1 7/8 | 1 7/8 | 2 1/2 | 4 | 2 |

| 1 1/2 | 48.3 | 1.900 | 1 1/2 | 2 1/4 | 2 1/4 | 2 7/8 | 4 | 2 |

| 2 | 60.3 | 2.375 | 1 1/2 | 2 1/2 | 2 1/2 | 3 5/8 | 6 | 2 1/2 |

| 2 1/2 | 73.0 | 2.875 | 1 1/2 | 3 | 3 | 4 1/8 | 6 | 2 1/2 |

| 3 | 88.9 | 3.500 | 2 | 3 3/8 | 3 3/8 | 5 | 6 | 2 1/2 |

| 3 1/2 | 101.6 | 4.000 | 2 1/2 | 3 3/4 | 3 3/4 | 5 1/2 | 6 | 3 |

| 4 | 114.3 | 4.500 | 2 1/2 | 4 1/8 | 4 1/8 | 6 3/16 | 6 | 3 |

| 5 | 141.3 | 5.563 | 3 | 4 7/8 | 4 7/8 | 7 5/16 | 8 | 3 |

| 6 | 168.3 | 6.625 | 3 1/2 | 5 5/8 | 5 5/8 | 8 1/2 | 8 | 3 1/2 |

| 8 | 219.1 | 8.625 | 4 | 7 | 7 | 10 5/8 | 8 | 4 |

| 10 | 273.1 | 10.750 | 5 | 8 1/2 | 8 1/2 | 12 3/4 | 10 | 5 |

| 12 | 323.9 | 12.750 | 6 | 10 | 10 | 15 | 10 | 6 |

We Are Largest Independent S32750 Super Duplex Fittings Manufacturer In India And Check SDSS 1.4410 Pipe End Cap Specification List.

Alloy S32750 Buttweld Fittings Specification List

| Specification Chart Of: | UNS S32750 Pipe Fittings |

| Type Of Pipe Connection | End Bell/ Flange/ Clamp End/ Threaded/ Weld |

| Wall Thickness: | SCH 5S To SCH 180S |

| Standard Dimensions: | MSS-SP-43 Type B, JIS B2312, MSS-SP-43 Type A, ASME B16.9, JIS B2313, ASME B16.28 |

| Length Sizes: | NPS (1⁄₂”) to NPS (48”) |

| Top 5 Fittings Standards | DIN, EN, ISO, JIS, NPT |

| We Offer Type Of Fittings At Low Price | Tee, Reducer, Stub End, Bend, Adapter, Wye, Cross, Elbow, End Cap |

| Schedule Formula: | Schedule 10S TO Schedule 160S. |

| IBR Approved Manufacturer Of Steel Materials: | Copper, Iron (Ductile/Cast), Carbon Steel, Alloy Steel, Brass, Bronze, Cupro-Nickel 90/10 & 70/30, Nickel, Titanium, Chrome-molybdenum, Nickel Alloys, Tantalum, Stainless Steel, Inconel, Monel, Hastalloy |

| Maximum Pressure | Class 150 To Class 2500. |

Refer S32750 Super Duplex Weld Fittings Mechanical Properties And Size Chart Of A276 UNS S32750 Fittings.

UNS S32205 Mechanical Properties

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| UNS S32750 Pipe Fittings | 7.8 | 0.281 | 1350 | 2460 |

Weight Formula Of Super Duplex UNS S32750 Elbow

DN (Normal Pipe Size) For ASME B16.9 |

Schedule 10S |

Schedule 40S |

Schedule 80S |

||||||

Elbow 90 Deg |

Elbow 45 Deg | B16.9 Equal Tee | Elbow 90 Deg |

Elbow 45 Deg | B16.9 Equal Tee |

Elbow 90 Deg | Elbow 45 Deg | B16.9 Equal Tee |

|

8 |

0.02 |

0.01 |

0.03 |

0.03 |

0.02 |

0.06 |

0.04 |

0.03 |

0.07 |

10 |

0.03 |

0.02 |

0.05 |

0.03 |

0.02 |

0.03 |

0.06 |

0.04 |

0.09 |

15 |

0.06 |

0.03 |

0.09 |

0.08 |

0.04 |

0.10 |

0.10 |

0.05 |

0.14 |

20 |

0.07 |

0.03 |

0.13 |

0.08 |

0.04 |

0.17 |

0.11 |

0.05 |

0.20 |

25 |

0.14 |

0.08 |

0.28 |

0.15 |

0.11 |

0.29 |

0.22 |

0.14 |

0.38 |

32 |

0.23 |

0.11 |

0.49 |

0.26 |

0.17 |

0.59 |

0.40 |

0.23 |

0.68 |

40 |

0.30 |

0.17 |

0.68 |

0.40 |

0.23 |

0.86 |

0.51 |

0.29 |

1.02 |

50 |

0.50 |

0.25 |

0.85 |

0.70 |

0.4 |

1.28 |

0.91 |

0.59 |

1.59 |

65 |

0.85 |

0.48 |

1.41 |

1.40 |

0.77 |

2.19 |

1.81 |

0.99 |

3.13 |

80 |

1.25 |

0.63 |

1.77 |

2.20 |

1.08 |

3.31 |

2.97 |

1.50 |

4.45 |

90 |

1.70 |

0.75 |

2.67 |

2.83 |

1.42 |

4.08 |

4.00 |

2.00 |

5.44 |

100 |

2.10 |

1.08 |

3.46 |

4.47 |

2.09 |

5.27 |

6.18 |

2.81 |

7.71 |

150 |

5.45 |

2.72 |

8.07 |

10.89 |

5.44 |

10.99 |

16.32 |

8.16 |

13.61 |

200 |

10.20 |

5.33 |

15.65 |

21.54 |

10.77 |

20.91 |

33.11 |

16.56 |

28.12 |

250 |

18.15 |

9.75 |

26.46 |

38.56 |

19.27 |

35.38 |

51.71 |

25.86 |

49.90 |

300 |

25.80 |

13.62 |

39.46 |

59.42 |

29.71 |

62.14 |

79.38 |

39.69 |

83.91 |

DN (Normal Pipe Sizes) For ASME B16.9 |

Schedule 10S |

Schedule 40S |

Schedule 80S |

||||||

| Concentric Pipe Reducer | Eccentric Pipe Reducer | Reducing And Unequal Tee | Concentric Pipe Reducer | Eccentric Pipe Reducer | Reducing And Unequal Tee | Concentric Pipe Reducer | Eccentric Pipe Reducer | Reducing And Unequal Tee | |

40x.25 |

0.19 |

0.19 |

0.60 |

0.26 |

0.26 |

0.76 |

0.34 |

0.34 |

0.90 |

50x25 |

0.28 |

0.28 |

0.73 |

0.40 |

0.40 |

1.10 |

0.54 |

0.54 |

1.37 |

50x40 |

0.31 |

0.31 |

0.76 |

0.45 |

0.45 |

1.15 |

0.59 |

0.59 |

1.43 |

80x.50 |

0.55 |

0.55 |

1.56 |

1.00 |

1.00 |

2.91 |

1.79 |

1.79 |

3.91 |

100x50 |

0.78 |

0.78 |

2.94 |

1.50 |

1.50 |

4.48 |

1.95 |

1.95 |

6.55 |

100x80 |

0.87 |

0.87 |

3.04 |

1.74 |

1.74 |

4.64 |

2.33 |

2.33 |

6.79 |

150x80 |

1.82 |

1.82 |

6.86 |

3.95 |

3.95 |

9.68 |

5.51 |

5.51 |

11.57 |

150x100 |

1.96 |

1.96 |

7.10 |

4.07 |

4.07 |

11.94 |

5.96 |

5.96 |

11.97 |

200x100 |

3.01 |

3.01 |

13.46 |

6.55 |

6.55 |

17.98 |

9.23 |

9.23 |

24.18 |

200x150 |

3.19 |

3.19 |

14.08 |

6.74 |

6.74 |

18.82 |

10.12 |

10.12 |

25.31 |

Best Deals On Bulk Procurement Of SAE S32750 Concentric Reducer And UNS S32750 Pipe Nipple For Piping Connection.

UNS S32205 Duplex Stainless Steel Reducer Size Chart

| O.D. or I.D. Diameter | Equivalent Decimal | Nominal Diameter | Typical Threads In Inch |

| 5/16 | 0.313 | 1/16 | 27 |

| 13/32 | 0.405 | 1/8 | 27 |

| 35/64 | 0.540 |

1/4 | 18 |

| 43/64 | 0.675 | 3/8 | 18 |

| 27/32 | 0.840 | 1/2 | 14 |

| 1-3/64 | 1.050 | 3/4 | 14 |

| 1-5/16 | 1.315 | 1 | 11-1/2 |

1-21/32 |

1.660 | 1-1/4 | 11-1/2 |

| 1-29/32 | 1.900 | 1-1/2 | 11-1/2 |

| 2-3/8 | 2.375 | 2 | 11-1/2 |

| 2-7/8 | 2.875 | 2-1/2 | 8 |

| 3-1/2 | 3.500 | 3 | 8 |

| 4 | 4.000 | 3-1/2 | 8 |

| 4-1/2 | 4.500 | 4 | 8 |

ASME SA 276 S32750 End Cap Tolerance Formula

| UNS S32750 Pipe Fittings Tolerance | 90 Deg And 45 Deg Elbows And Pipe Tee |

Reducer (Concentric/ Eccentric) & Lap Joint Stub End (Long / Short) |

Pipe End Caps | |||

| Normal Pipe Size (NPS) Of ASME B16.9 | O. (Outside) D. (Daimeter) at Bevel |

I. (Inside) D.(Daimeter) at End |

Wall Thickness Of T | Center-to-End Dimension A ,C ,B |

Over-all Length Of H |

Over-all Length Of F |

| 1/2 to 2-1/2 | +0.06 | Not less than 87.5% of nominal thickness |

+/- 0.06 | +/- 0.06 | +/- 0.12 | |

| -0.03 | ||||||

| 3 to 3-1/2 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 4 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 5 to 8 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.25 | |

| 10 to 18 | +0.16 | +/- 0.12 | +/- 0.09 | +/- 0.09 | +/- 0.25 | |

| -0.12 | ||||||

| 20 to 24 | +0.25 | +/- 0.19 | +/- 0.09 | +/- 0.09 | +/- 0.25 | |

| -0.19 | ||||||

| 26 to 30 | +0.25 | +/- 0.19 | +/- 0.12 | +/- 0.19 | +/- 0.38 | |

| -0.19 | ||||||

| 32 to 48 | +0.25 | +/- 0.19 | +/- 0.19 | +/- 0.19 | +/- 0.38 | |

| -0.19 | ||||||

Pressure Test Of ASTM A276 UNS S32750 Reducing Tee

| Pressure-Temperature ratings for UNS S32750 Pipe Fittings (psig) | |||||

|---|---|---|---|---|---|

| Temperature Ratings | Pressure Class | ||||

| 150 | 300 | ||||

| 1/4 - 1 inch. | 1 1/4 - 2 inch. | 2 1/2 - 3 inch. | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |

S32750 Super Duplex Fittings Ring Gasket Chart

| O.D. or I.D. Diameter | Equivalent Decimal | Nominal Diameter | Typical Threads In Inch |

| 5/16 | 0.313 | 1/16 | 27 |

| 13/32 | 0.405 | 1/8 | 27 |

| 35/64 | 0.540 |

1/4 | 18 |

| 43/64 | 0.675 | 3/8 | 18 |

| 27/32 | 0.840 | 1/2 | 14 |

| 1-3/64 | 1.050 | 3/4 | 14 |

| 1-5/16 | 1.315 | 1 | 11-1/2 |

1-21/32 |

1.660 | 1-1/4 | 11-1/2 |

| 1-29/32 | 1.900 | 1-1/2 | 11-1/2 |

| 2-3/8 | 2.375 | 2 | 11-1/2 |

| 2-7/8 | 2.875 | 2-1/2 | 8 |

| 3-1/2 | 3.500 | 3 | 8 |

| 4 | 4.000 | 3-1/2 | 8 |

| 4-1/2 | 4.500 | 4 | 8 |

SUPER DUPLEX STEEL UNS S32750 PIPES FITTING CHEMICAL COMPOSITION

| Grade | C | Mn | Si | P | S | Cr | Ni | Mo | N | Fe |

| Super Duplex S32750 | 0.030 max. | 2.00 max. | 1.00 max. | 0.030 max. | 0.020 max. | 22.0 – 23.0 | 4.50 – 6.50 | 3.0 – 3.5 | 0.14 – 0.20 | 63.72 min. |

| Super Duplex S32760 | 0.030 max. | 2.00 max. | 1.00 max. | 0.030 max. | 0.020 max. | 21.0 – 23.0 | 4.50 – 6.50 | 2.50 – 3.50 | 0.08 – 0.20 | 63.54 min |

SUPER DUPLEX STEEL UNS S32760 PIPES FITTING MECHANICAL PROPERTIES

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Super Duplex S32750 | 7.805 | 0.285 | 1420 – 1465 | 2588 – 2669 | |

| Super Duplex S32760 | 7.805 | 0.285 | 1420 – 1465 | 2588 – 2669 |

Equivalent of ASTM A815 DSS Pipe Elbow

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex 2205 | 1.4462 | S31803 / S32205 |

UNS S32750 Fittings Weight Chart

| Nom. Pipe Size | ASTM A815 Duplex Steel 90° Elbows | ASTM A815 Duplex Steel 45° Elbows | ASTM A815 Duplex Steel 180° Return Long Radius | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Long Radius | Short Radius | 3R | Long Radius | 3R | STD | XS | ||||||||

| STD | XS | SCH. 160 | XXS | STD | XS | STD | XS | STD | XS | STD | XS | |||

| ½ | .18 | .25 | – | – | – | – | – | – | .09 | .19 | – | – | .35 | – |

| ¾ | .19 | .25 | – | – | – | – | – | – | .09 | .19 | – | – | .40 | .65 |

| 1 | .40 | .50 | .60 | .75 | .25 | – | – | – | 0.25 | .31 | – | – | .75 | 1.00 |

| 1¼ | .60 | .90 | 1.00 | 1.38 | .4 | – | – | – | 0.38 | .50 | – | – | 1.25 | 1.75 |

| 1½ | .90 | 1.15 | 1.80 | 1.50 | .56 | .75 | – | – | .40 | .69 | – | – | 1.88 | 2.39 |

| 2 | 1.60 | 2.20 | 3.25 | 3.50 | 1.00 | 1.50 | 3.00 | 4.00 | .81 | 1.19 | 1.5 | 2.1 | 3.23 | 4.40 |

| 2½ | 3.25 | 4.00 | 5.13 | 7.00 | 2.13 | 2.80 | 6.00 | 8.00 | 1.75 | 2.13 | 3.00 | 4.00 | 6.50 | 8.00 |

| 3 | 5.00 | 6.50 | 8.50 | 11.0 | 3.00 | 4.25 | 10.0 | 13.0 | 2.63 | 3.50 | 5.00 | 7.00 | 10.25 | 13.00 |

| 3½ | 6.75 | 8.35 | – | 16.0 | 4.50 | 6.00 | 13.0 | 18.0 | 3.50 | 4.50 | 7.00 | 9.00 | 13.00 | 16.75 |

| 4 | 9.00 | 13.5 | 18.0 | 20.0 | 6.25 | 8.50 | 18.0 | 25.0 | 4.50 | 6.10 | 9.00 | 13.0 | 18.5 | 25.0 |

| 5 | 15.0 | 22.0 | 32.0 | 36.0 | 9.60 | 14.0 | 29.0 | 43.0 | 7.50 | 10.7 | 15.0 | 22.0 | 30.0 | 44.0 |

| 6 | 24.5 | 35.0 | 57.0 | 65.0 | 18.0 | 23.0 | 45.0 | 70.0 | 12.0 | 17.5 | 23.0 | 35.0 | 50.0 | 70.0 |

| 8 | 50.0 | 71.0 | 120 | 118 | 34.0 | 47.5 | 90.0 | 140 | 23.0 | 35.0 | 45.0 | 70.0 | 95.0 | 142 |

| 10 | 88.0 | 107 | 260 | – | 58.0 | 70.0 | 159 | 218 | 43.0 | 53.0 | 80.0 | 109 | 117 | 215 |

| 12 | 125 | 160 | 450 | – | 80.0 | 104 | 233 | 310 | 62.0 | 84.0 | 117 | 155 | 230 | 320 |

| 14 | 160 | 205 | 572 | – | 105 | 140 | 298 | 400 | 80.0 | 100 | 149 | 200 | 325 | 400 |

| 16 | 206 | 276 | – | – | 132 | 174 | 390 | 520 | 100 | 135 | 195 | 260 | 412 | 550 |

| 18 | 260 | 340 | – | – | 167 | 219 | 495 | 660 | 126 | 167 | 248 | 330 | 510 | 690 |

| 20 | 320 | 420 | – | – | 210 | 275 | 610 | 810 | 160 | 206 | 305 | 405 | 640 | 830 |

| 22 | 394 | 520 | – | – | – | – | 735 | 980 | 197 | 260 | 368 | 490 | 787 | 1040 |

| 24 | 460 | 600 | – | – | 298 | 392 | 875 | 1170 | 238 | 300 | 438 | 585 | 890 | 1200 |

| 26 | 550 | 729 | – | – | – | – | 1030 | 1370 | 275 | 365 | 515 | 685 | – | – |

| 30 | 734 | 975 | – | – | – | – | 1370 | 1830 | 367 | 488 | 685 | 915 | – | – |

| 36 | 1062 | 1412 | – | – | – | – | 1970 | 2630 | 531 | 706 | 985 | 1315 | – | – |

General characteristics

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2507 | 1.4410 | 2507 | S32750 | 43 | 20 | 550 | D | 0.02 | 25.0 | 7.0 | 4.0 | 0.27 |

| 2205 stainless steel grades | Industry Specifications | UNS |

| Duplex 2507 2507 (EN 1.4410/UNS S32750) A super duplex product with higher corrosion resistance and mechanical strength than Forta DX 2205. Often used in extremely corrosive environments. |

• Desalination plants • Industrial piping • Scrubbers • Oil and gas industry, typically tubular products, flanges,fittings and valves • Deep-sea pipelines |

• Cold rolled coil and sheet • Hot rolled coil and sheet • Quarto plate • Bar • Wire rod • Semi-finished (bloom, billet, ingot & slab) |

| Duplex 32760 100 (EN 1.4501/UNS S32760) A super duplex product with higher corrosion resistance and mechanical strength than Forta DX 2205. Often used in extremely corrosive environments. |

• Desalination plants • Industrial piping • Scrubbers • Oil and gas industry, typically tubular products, flanges, fittings and valves • Deep-sea pipelines |

• Cold rolled coil and sheet • Hot rolled coil and sheet • Quarto plate • Bar • Wire rod • Semi-finished (bloom, billet, ingot & slab) |

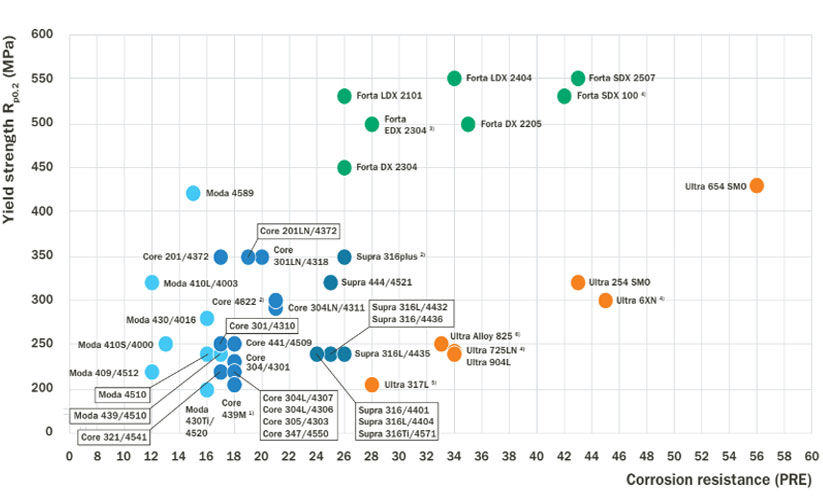

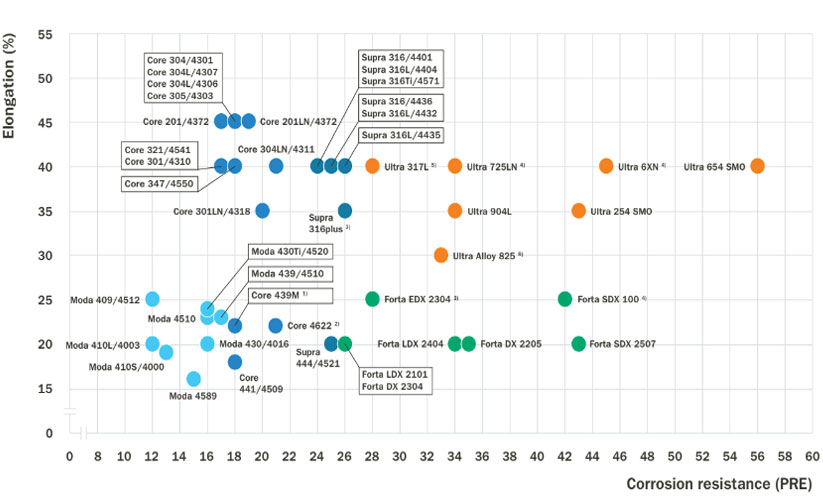

Performance

Elongation vs. corrosion resistance.

Elongation vs. Corrosion resistance

Strength vs. Corrosion resistance

Elongation vs. Corrosion resistance

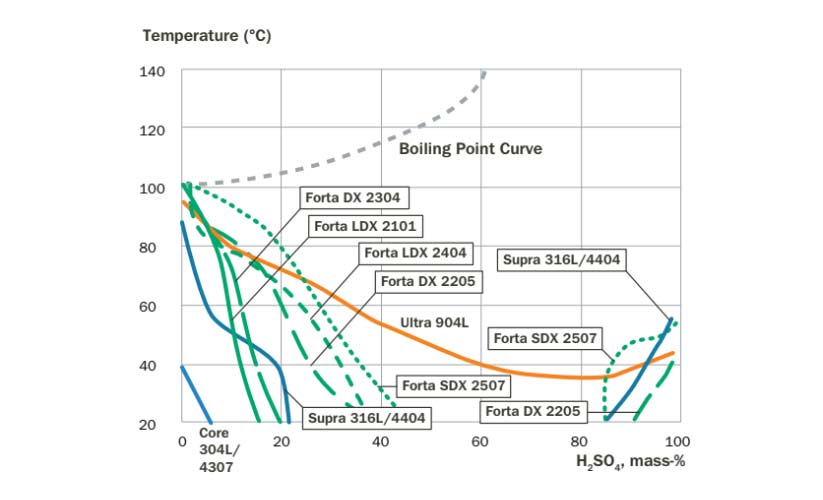

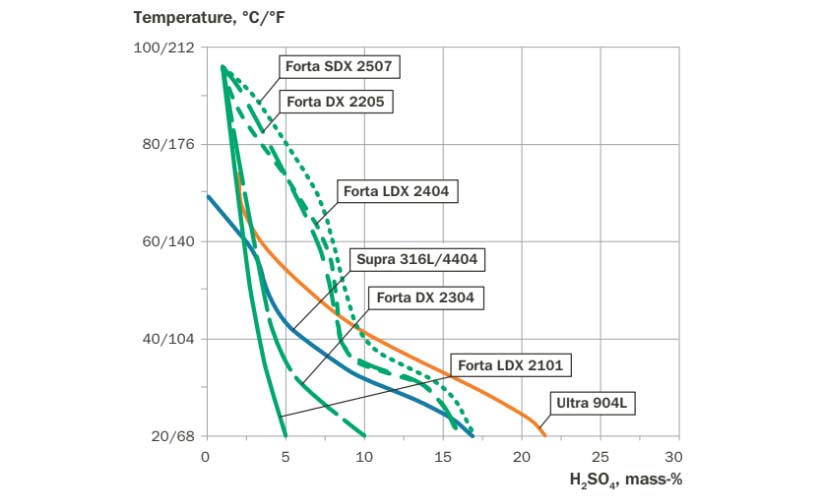

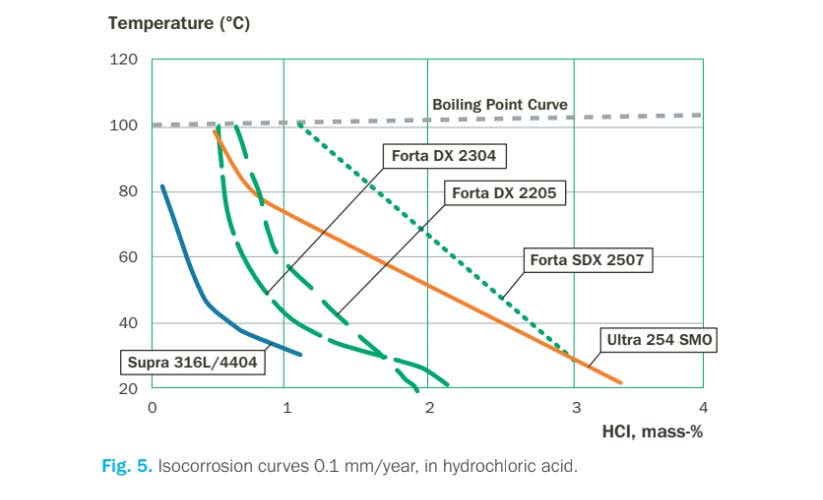

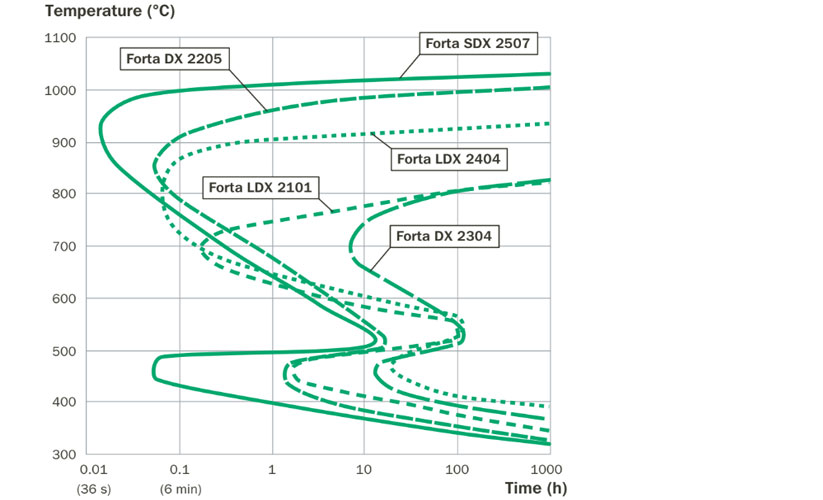

Duplex stainless steels, known for their high chromium content, provide excellent corrosion resistance, particularly in uniform corrosion environments with rates below 0.1 mm/year. Forta DX 2205 shows superior resistance to chloride-contaminated sulfuric acid compared to traditional stainless steels like Supra 316L/4404, approaching the performance of Ultra 904L. In dilute hydrochloric acid, Forta SDX 2507 and similar high-alloyed duplex steels are suitable, though localized corrosion risks exist around crevices even within safe usage limits.

Corrosion resistance

- Uniform Corrosion: Due to high chromium content, these steels resist uniform corrosion well, typically less than 0.1 mm/year.

- Sulfuric Acid: DX 2205 shows superior resistance in sulfuric acid contaminated by chloride ions compared to Supra 316L/4404.

- Hydrochloric Acid: SDX 2507 and DX 2205 can be used in dilute hydrochloric acid, with potential risks of localized corrosion in crevices.

- Nitric Acid: LDX 2101 and DX 2304, with their high chromium content and low molybdenum, are suitable for environments where resistance to strongly oxidizing nitric acid is needed.

PRE values for Forta Duplex grades and some austenitic grades

Steel designations |

PRE |

|||

| name | EN | ASTM Type |

UNS | |

| 2205 | 1.4462 | 2205 | S32205 | 35 |

| 2507 | 1.4410 | 2507 | S32750 | 43 |

Results from stress corrosion cracking immersion tests in chloride solutions

| name | ASTM G123 | ASTM G36 | ||

| 25% NaCl, pH 1.5, 106°C (b.p.), 1,000 h | 40% CaCl2, 100°C, 500 h | 45% MgCl2, 155°C (b.p.), 24 h | ||

| U-bend samples | 4-PB samples (90% of Rp0.2) | U-bend samples | ||

| 2205 | No SCC | No SCC | SCC | |

| 2507 | No SCC | No SCC | SCC | |

Mechanical properties according to EN 10088 and EN 10028

| EN | ASTM | Product form | Yield strength | Tensile | Elongation | Elongation | |

| name | UNS | Rp0.2[MPa] | strength | A[%] | A80[%] | ||

| Rm[MPa] | |||||||

| 2507 | 1.4410 | S32750 | Cold rolled coil (C) | 550 | 750–1000 | 20 | 20 |

| Hot rolled coil (H) | 530 | 750–1000 | 20 | 20 | |||

| Quarto plate (P) | 530 | 730–930 | 20 | 20 | |||

| Bar | 530 | 730–930 | 25 | – | |||

| 1.4510 | S32760 | Cold rolled coil (C) | 550 | 750–1000 | 20 | 20 | |

| Hot rolled coil (H) | 530 | 750–1000 | 25 | 25 | |||

| Quarto plate (P) | 530 | 730–930 | 25 | 25 |

Mechanical properties according to ASTM A240

| EN | ASTM | Product form | Yield | Yield | Tensile | Tensile | Elongation | |

| name | UNS | strength | strength | strength | strength | A50[%] | ||

| Rp0.2[MPa] | Rp0.2 [ksi] | Rm [MPa] | Rm [ksi] | |||||

| 2507 | 1.4410 | S32750 | Plate, sheet and strip | 550 | 80 | 795 | 116 | 15 |

| 100 | 1.4501 | S32760 | Plate, sheet and strip | 550 | 80 | 750 | 108 | 25 |

Mechanical properties at elevated temperatures, minimum yield strength according to EN 10028-7

| name | Strength | 100°C | 150°C | 200°C | 250°C | |

| 2507 | Tensile strength | Rm [MPa] | 680 | 660 | 640 | 630 |

Physical properties

Metric values according to EN 10088-1

| name | EN | ASTM Type | UNS | Density [kg/dm3] | Modulus of elasticity at 20°C [GPa] | Coefficient of thermal expansion 20–100°C [10-6/K] | Thermal conductivity at 20°C [W/(m x K)] | Thermal capacity at 20°C [J/(kg x K)] | Electrical resistivity at 20°C [Ω x mm2/m] |

| 2507 | 1.4410 | 2507 | S32750 | 7.8 | 200 | 13.0 | 15 | 500 | 0.8 |

| 100 | 1.4410 | - | S32760 | 7.8 | 200 | 13.0 | 15 | 500 | 0.8 |

Imperial values converted from Table 10

| name | Density [lbm/in3] | Modulus of elasticity [psi] | Coefficient of thermal expansion 68–212°F [μin / (in x °F)] | Thermal conductivity [Btu/(hr x ft x °F)] | Thermal capacity [Btu/(lbm x °F)] | Electrical resistivity [μΩ x in] |

| 2507 | 0.282 | 29 x 106 | 7.2 | 8.7 | 0.119 | 31.50 |

Fabrication

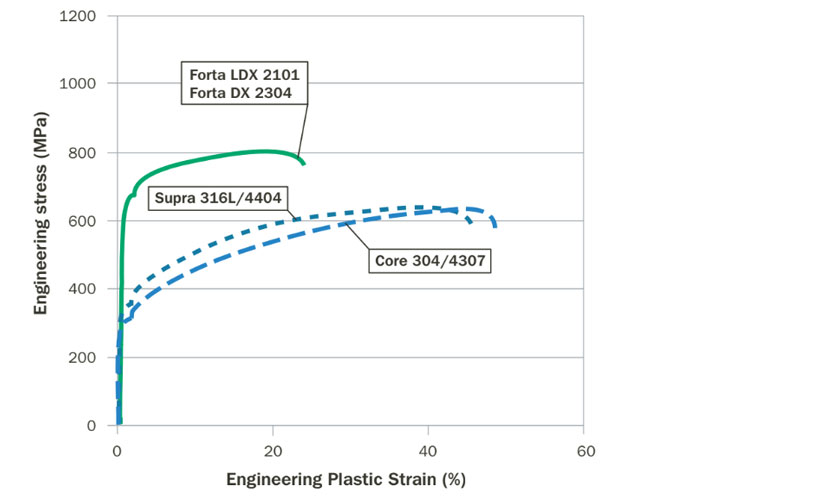

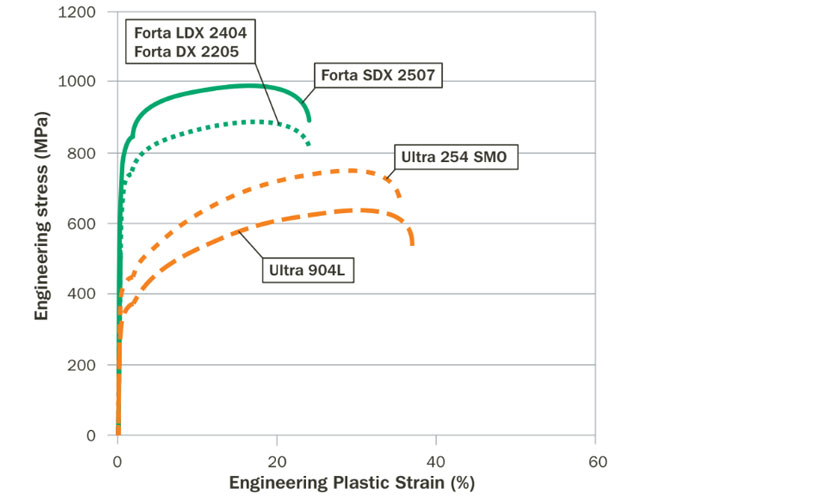

Duplex stainless steel is suitable for all forming processes used for stainless steel. The high yield strength compared to austenitic and ferritic stainless steel can however give differences in forming behavior. Depending on the chosen forming technique there could be consequences, such as increased springback. This point is particularly relevant to the forming of any high strength steel. Moreover, an excellent interplay between high yield strength, work hardening rate and elongation promote the duplex grades for light weight and cost-efficient applications with complex shapes. The impact of the high strength varies for different forming techniques. Common for all is that the estimated forming forces will be higher than for the corresponding austenitic and ferritic stainless steel grades. This effect will usually be lower than expected from just the increase in strength since the choice of duplex stainless steel is often associated with gauge reduction. It is important to consider that duplex stainless steel may also be more demanding on the tools and on the lubricant. This should also be noted when looking to down gauge.

Welding consumables

| name | EN | ASTM Type | UNS | Consumable ISO designation |

| 2507 | 1.4410 | 2507 | S32750 | 25 9 4 NL |

General characteristics

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2507 | 1.4410 | 2507 | S32750 | 43 | 20 | 550 | D | 0.02 | 25.0 | 7.0 | 4.0 | 0.27 |

Product

Quick contact

Get Solution

Organically grow the holistic world view of disruptive innovation via workplace diversity

Contact Us