- Chintamani Stainless Inc, 132, T.P. Streets, 6th Kumbharwada Lane, Mumbai- 400004, India

- Trophy Winning

- Ceritified ( ISO 9005-2010 )

Super Duplex Pipes & Tubes

Chintamani Stainless Inc is ISO 9001:2008 certified manufacturer, supplier and exporter of Super Duplex Steel Pipes & Tubes in India and worldwide.This saf 2507 super duplex stainless steel tube has been engineered for applications

requiring high tensile strength and corrosion resistance. The 2507 super duplex pipe,

for example, is used in a variety of industries, including chemical refining and

petrochemical applications, as well as seawater equipment.

Super Duplex 2507 Pipe is a stainless steel pipe with the main alloyants chromium,

nickel, and molybdenum. As a result of its chemical composition in terms of its maximum

alloyant content, this grade is also known as 25cr Super Duplex Pipe. This grade of

duplex 2507 Stainless Steel Pipe is well-known for its outstanding tolerance to chloride

ion stress-related corrosion cracking, which has been due to the alloy's duplex

microstructure.

Duplex 2507 pipe is used in a variety of industries, including mechanical and structural

components, injection and ballast water systems, corrosion-resistant parts, offshore

platforms, heat exchangers, fire-fighting systems,oil and gas industry equipment,

process and service water systems, desalination plants, high pressure RO-plant and

seawater piping, high strength, suitable for chemical process industries.

Sa 789 Uns S32750 Pipe is a super duplex stainless steel pipe with 25% chromium, 4%

molybdenum, and 7% nickel that is engineered for challenging applications requiring

outstanding strength and corrosion resistance, such as chemical process, petrochemical,

and seawater machinery.

A790 S32760 with reduced production costs when compared with equivalent austenitic and

ferritic grades and with greater yield and tensile strength, SuperDuplex is a

cost-effective option for the market, with lower processing costs as opposed to

comparable austenitic and ferritic grades and higher yield and tensile power. It is

possible that if SuperDuplex is used, content thicknesses for a project may be

minimised, lowering costs without sacrificing efficiency. ASTM A790 UNS S32750 is a

super duplex steel variant.

Specification

| ASTM Specification | ASTM A 789/ ASME SA 789 |

|---|---|

| Standard | JIS, TOCT, GB, AMS, EN, ASTM, AISI, SAE, ASME, DS, NF, DTD, DIN |

| ASTM A790 Super Duplex 2507 Welded Pipe Size | 5.0 - 1219.2 mm |

| Super Duplex 2507 Seamless Pipe Size | 4 to 219mm W. T.: 0.5 to 20mm |

| 25cr Super Duplex EFW Pipe size | 5.0 - 1219.2 mm |

| UNS S32750 Pipe Outer Diameter | 6.00 mm OD up to 250 mm OD, Sizes up to 12” NB |

| WERKSTOFF NR. 1.4410 Pipe Schedule | SCH5, SCH140, SCH80, XS, SCH10, SCH10S, SCH80, XXS, SCH120, SCH60, SCH30, STD, SCH20, SCH40S, SCH160, SCH40 |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Finish | BA (Bright & Annealed), Polished, AP (Annealed & Pickled), NO.1, MF, 2B, NO.4, HL, BA, Mirror finish, 8K etc |

| Saf 2507 Pipe Length | Single Random, Standard & Cut length , Double Random Pipe |

| Super Duplex 2507 Seamless Tube Size | 3.35 mm OD To 101.6 mm OD, 15 NB to 150 NB IN |

| Alloy 2507 Welded Tube Size | 6.35 mm OD To 152 mm OD |

| wall thickness of Super Duplex 2507 tubing | (special/custom wall thicknesses available) 0.020" –0.220" |

| Form | Super Duplex 2507 Pipe are available in form of Square, Round, Rectangular, Hollow, Coiled, Hydraulic, Straight Pipes, Pan Cake Coils, “U” Shape etc. |

| End of Super Duplex 2507 Pipe | Beveled End, Plain End, Screwed ends, Treaded Pipe |

| Type of S32760 Pipe | ERW/ Seamless / Welded / EFW / CDW / Fabricated /CEW/ DOM Super Duplex 2507 Pipe |

| Application of Super Duplex 2507 Pipe | Gas Tube, Oil Tube, Boiler and Heatexchanger, Fluid Tube |

| Marking on UNS S32750 Pipe | All ASTM A790 Super Duplex 2507 Pipes are marked as follows: Grade, Standard, Thickness, OD, Heat No. (Or according to the customer’s request.), Length |

| Specialize in |

|

| Value Added Service | Polish (Electro & Commercial) Annealed & Pickled Bending, Draw & Expansion as per required Size & Length, Machining Etc. |

| manufacturing Technique of Super Duplex 2507 Pipe | hot drawn, Cold drawn, solid solution, bright annealed, hot extruding |

| Test Certificate of 25cr Super Duplex Pipe |

|

| Our stockyard of Super Duplex 2507 Pipe | Abu Dhabi, Pimpri-Chinchwad, Port-of-Spain, New Delhi, Gimhae-si, Calgary, Gujarat, Istanbul, Dammam, Hyderabad, Tehran, Ludhiana, India, Ankara, Bangalore, Chennai, Ranchi, Coimbatore, Mumbai, Baroda, Noida, Thiruvananthapuram, Ahvaz, Surat, Ahmedabad, Bengaluru, Gurgaon, Kuwait, Riyadh, Mexico Montreal, Perth, Muscat, Melbourne, Tau, Bogota, Sydney, Jamshedpur, Courbevoie, Karachi, Nagpur,Indore, Lagos, Kolkata, Santiago, Ernakulam, Manama, Vadodara, Caracas, Khobar, Rajkot, London, Janeiro, Howrah, Kanpur, |

| Material Test Certificates (MTC) |

|

| Super Duplex 2507 Pipe Dimension ANSI/ ASME B36.10, B36.19, B2.1 We can also thread, cut and groove UNS S32750 Pipe to meet your specifications. | |

Equivalent of ASTM A815 DSS Pipe Elbow

| Alloy | UNS Designation | Werkstoff NR. | Specifications | AFNOR | Grade | 1.4410 |

|---|---|---|---|---|---|---|

| Super Duplex 2507 | S32750 | 1.4410 | A/SA789, A/SA790 | Z3 CN 25.06 Az | F53 | X2 Cr Ni MoN 25.7.4 |

CHEMICAL COMPOSITION

| S32750 / S32760 | C | N | P | Si | Mn | Mo | Ni | Cr | S | Other |

| 0.030 | 0.24/0.32 | 0.035 | 0.80 | 1.20 | 3.0/5.0 | 6.00/8.00 | 24.0/26.0 | 0.020 | Cu:0.50 |

MECHANICAL PROPERTIES

| S32750 / S32760 | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80000 , MPa – 550 | Psi – 116000 , MPa – 800 | 15 % |

UNS S32205 Seamless Pipes are supplied according to ANSI/ ASME B36.19.

OD = Duplex 2205 Pipe outside diameter

WT = Duplex 2205 Pipe wall thickness

Super Duplex Stainless Steel Pipe Size Chart In Inches

| 1/8″ IPS(.405″ O.D.) | 3 1/2″ IPS( 4.000″ O.D.) |

|---|---|

| SCH 40, 80 | SCH 10, 40, 80, 160, XXH |

| 1/4″ IPS(.540″ O.D.) | 4″ IPS(4.500″ O.D.) |

| SCH 10, 40, 80 | SCH 10, 40, 80, 160, XXH |

| 3/8″ IPS(.675″ O.D.) | 5″ IPS( 5.563″ O.D.) |

| SCH 10, 40, 80 | SCH 10, 40, 80, 160, XXH |

| 1/2″ IPS(.840″ O.D.) | 6″ IPS(6.625″ O.D.) |

| SCH 5, 10, 40, 80, 160, XXH | SCH 5, 10, 40, 80, 120, 160, XXH |

| 3/4″ IPS(1.050″ O.D.) | 8 ” IPS(8.625″ O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH 5, 10, 40, 80, 120, 160, XXH |

| 1″ IPS:(1.315′ O.D.) | 10″ IPS(10.750″ O.D.) |

| SCH 5, 10, 40, 80, 160, XXH | SCH 10, 20, 40, 80 (.500), TRUE 80(.500) |

| 1-1/4″ IPS(1.660″ O.D.) | 12″ IPS(12.750″ O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH 10, 20, 40(.375), TRUE40(.406), SCH80(.500) |

| 1-1/2″ IPS(1.900″ O.D.) | 14″ IPS(14.000″ O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH10 (.188), SCH40 (.375) |

| 2″ IPS(2.375″ O.D.) | 16″ IPS(16.000″ O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH10(.188), SCH40(.375) |

| 2 1/2″ IPS(2.875″ O.D.) | 18″ IPS (18.000″ O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH-40 (.375) |

| 3″ IPS( 3.500″ O.D.) | |

| SCH 5, 10, 40, 80, 160, XXH |

General characteristics

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2507 | 1.4410 | 2507 | S32750 | 43 | 20 | 550 | D | 0.02 | 25.0 | 7.0 | 4.0 | 0.27 |

| 2205 stainless steel grades | Industry Specifications | UNS |

| Duplex 2507 2507 (EN 1.4410/UNS S32750) A super duplex product with higher corrosion resistance and mechanical strength than Forta DX 2205. Often used in extremely corrosive environments. |

• Desalination plants • Industrial piping • Scrubbers • Oil and gas industry, typically tubular products, flanges,fittings and valves • Deep-sea pipelines |

• Cold rolled coil and sheet • Hot rolled coil and sheet • Quarto plate • Bar • Wire rod • Semi-finished (bloom, billet, ingot & slab) |

| Duplex 32760 100 (EN 1.4501/UNS S32760) A super duplex product with higher corrosion resistance and mechanical strength than Forta DX 2205. Often used in extremely corrosive environments. |

• Desalination plants • Industrial piping • Scrubbers • Oil and gas industry, typically tubular products, flanges, fittings and valves • Deep-sea pipelines |

• Cold rolled coil and sheet • Hot rolled coil and sheet • Quarto plate • Bar • Wire rod • Semi-finished (bloom, billet, ingot & slab) |

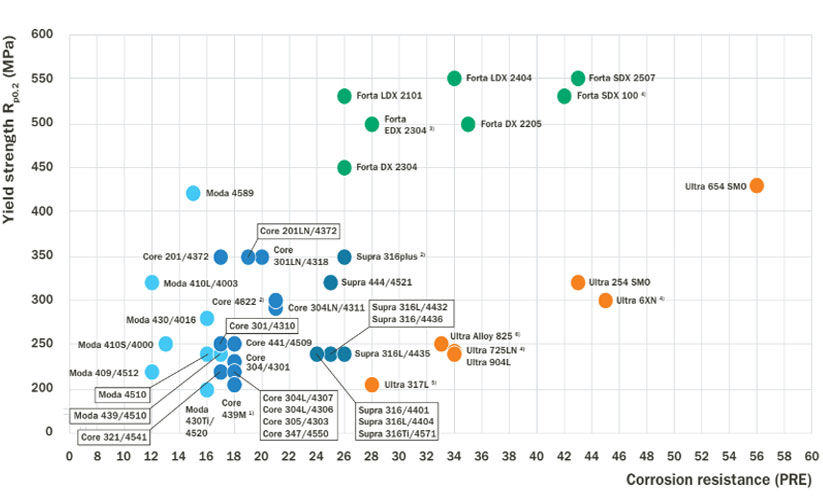

Performance

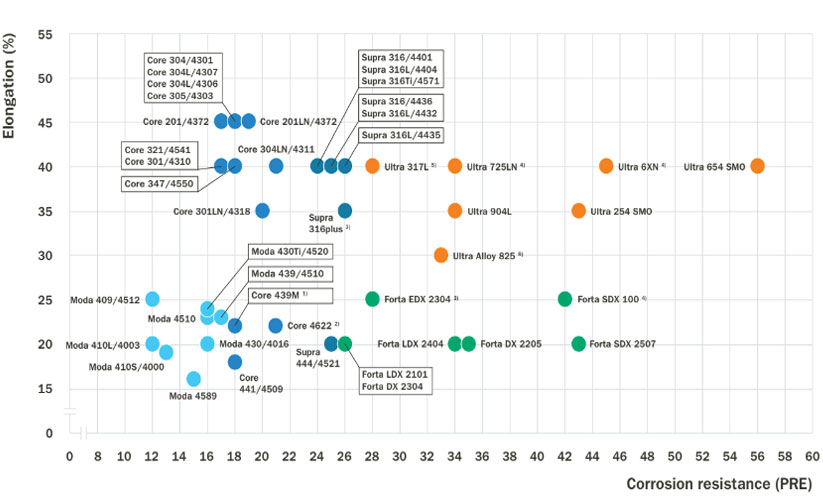

Elongation vs. corrosion resistance.

Elongation vs. Corrosion resistance

Strength vs. Corrosion resistance

Elongation vs. Corrosion resistance

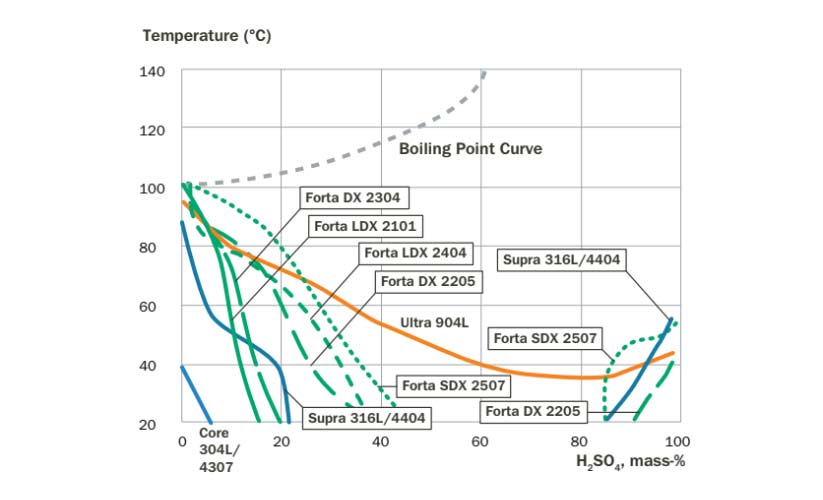

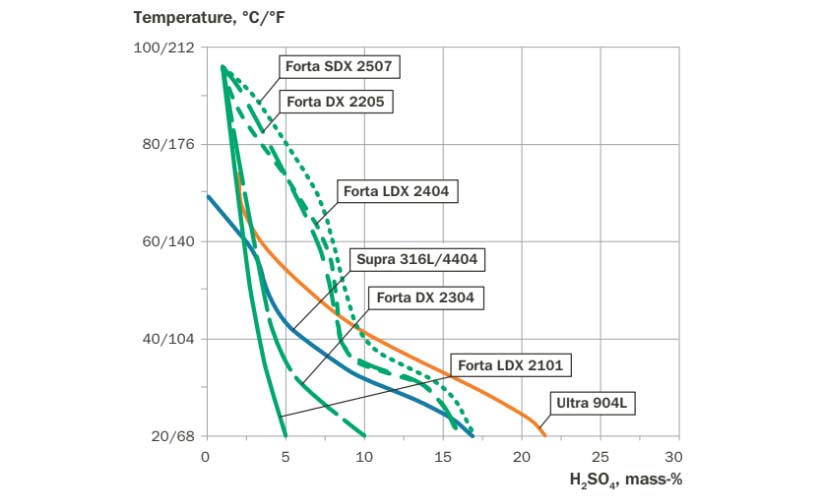

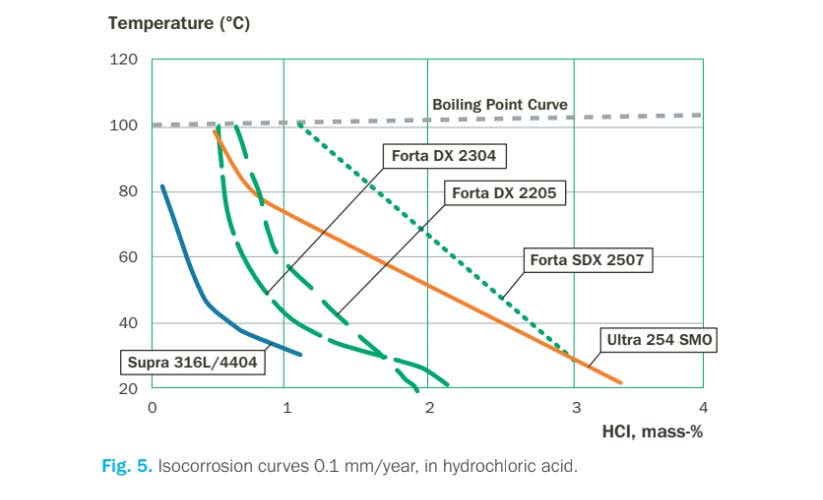

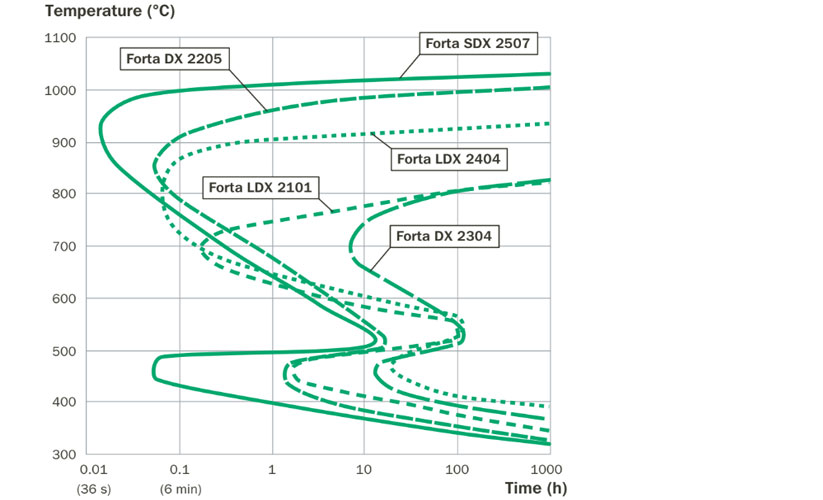

Duplex stainless steels, known for their high chromium content, provide excellent corrosion resistance, particularly in uniform corrosion environments with rates below 0.1 mm/year. Forta DX 2205 shows superior resistance to chloride-contaminated sulfuric acid compared to traditional stainless steels like Supra 316L/4404, approaching the performance of Ultra 904L. In dilute hydrochloric acid, Forta SDX 2507 and similar high-alloyed duplex steels are suitable, though localized corrosion risks exist around crevices even within safe usage limits.

Corrosion resistance

- Uniform Corrosion: Due to high chromium content, these steels resist uniform corrosion well, typically less than 0.1 mm/year.

- Sulfuric Acid: DX 2205 shows superior resistance in sulfuric acid contaminated by chloride ions compared to Supra 316L/4404.

- Hydrochloric Acid: SDX 2507 and DX 2205 can be used in dilute hydrochloric acid, with potential risks of localized corrosion in crevices.

- Nitric Acid: LDX 2101 and DX 2304, with their high chromium content and low molybdenum, are suitable for environments where resistance to strongly oxidizing nitric acid is needed.

PRE values for Forta Duplex grades and some austenitic grades

Steel designations |

PRE |

|||

| name | EN | ASTM Type |

UNS | |

| 2205 | 1.4462 | 2205 | S32205 | 35 |

| 2507 | 1.4410 | 2507 | S32750 | 43 |

Results from stress corrosion cracking immersion tests in chloride solutions

| name | ASTM G123 | ASTM G36 | ||

| 25% NaCl, pH 1.5, 106°C (b.p.), 1,000 h | 40% CaCl2, 100°C, 500 h | 45% MgCl2, 155°C (b.p.), 24 h | ||

| U-bend samples | 4-PB samples (90% of Rp0.2) | U-bend samples | ||

| 2205 | No SCC | No SCC | SCC | |

| 2507 | No SCC | No SCC | SCC | |

Mechanical properties according to EN 10088 and EN 10028

| EN | ASTM | Product form | Yield strength | Tensile | Elongation | Elongation | |

| name | UNS | Rp0.2[MPa] | strength | A[%] | A80[%] | ||

| Rm[MPa] | |||||||

| 2507 | 1.4410 | S32750 | Cold rolled coil (C) | 550 | 750–1000 | 20 | 20 |

| Hot rolled coil (H) | 530 | 750–1000 | 20 | 20 | |||

| Quarto plate (P) | 530 | 730–930 | 20 | 20 | |||

| Bar | 530 | 730–930 | 25 | – | |||

| 1.4510 | S32760 | Cold rolled coil (C) | 550 | 750–1000 | 20 | 20 | |

| Hot rolled coil (H) | 530 | 750–1000 | 25 | 25 | |||

| Quarto plate (P) | 530 | 730–930 | 25 | 25 |

Mechanical properties according to ASTM A240

| EN | ASTM | Product form | Yield | Yield | Tensile | Tensile | Elongation | |

| name | UNS | strength | strength | strength | strength | A50[%] | ||

| Rp0.2[MPa] | Rp0.2 [ksi] | Rm [MPa] | Rm [ksi] | |||||

| 2507 | 1.4410 | S32750 | Plate, sheet and strip | 550 | 80 | 795 | 116 | 15 |

| 100 | 1.4501 | S32760 | Plate, sheet and strip | 550 | 80 | 750 | 108 | 25 |

Mechanical properties at elevated temperatures, minimum yield strength according to EN 10028-7

| name | Strength | 100°C | 150°C | 200°C | 250°C | |

| 2507 | Tensile strength | Rm [MPa] | 680 | 660 | 640 | 630 |

Physical properties

Metric values according to EN 10088-1

| name | EN | ASTM Type | UNS | Density [kg/dm3] | Modulus of elasticity at 20°C [GPa] | Coefficient of thermal expansion 20–100°C [10-6/K] | Thermal conductivity at 20°C [W/(m x K)] | Thermal capacity at 20°C [J/(kg x K)] | Electrical resistivity at 20°C [Ω x mm2/m] |

| 2507 | 1.4410 | 2507 | S32750 | 7.8 | 200 | 13.0 | 15 | 500 | 0.8 |

| 100 | 1.4410 | - | S32760 | 7.8 | 200 | 13.0 | 15 | 500 | 0.8 |

Imperial values converted from Table 10

| name | Density [lbm/in3] | Modulus of elasticity [psi] | Coefficient of thermal expansion 68–212°F [μin / (in x °F)] | Thermal conductivity [Btu/(hr x ft x °F)] | Thermal capacity [Btu/(lbm x °F)] | Electrical resistivity [μΩ x in] |

| 2507 | 0.282 | 29 x 106 | 7.2 | 8.7 | 0.119 | 31.50 |

Fabrication

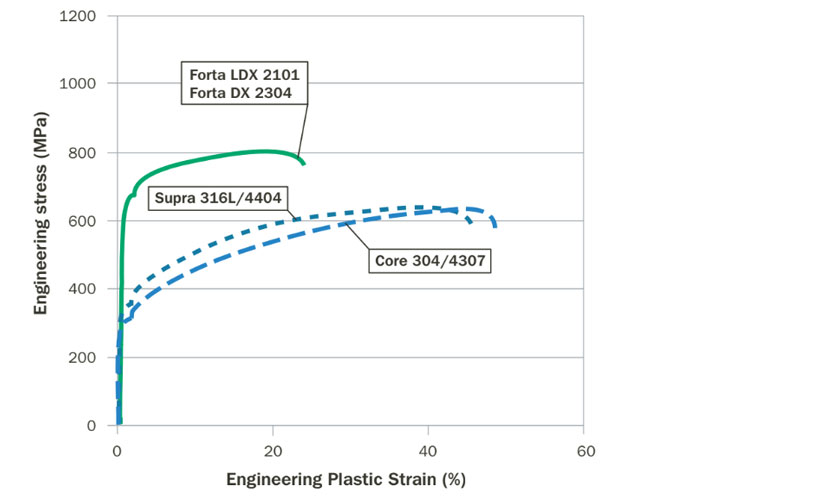

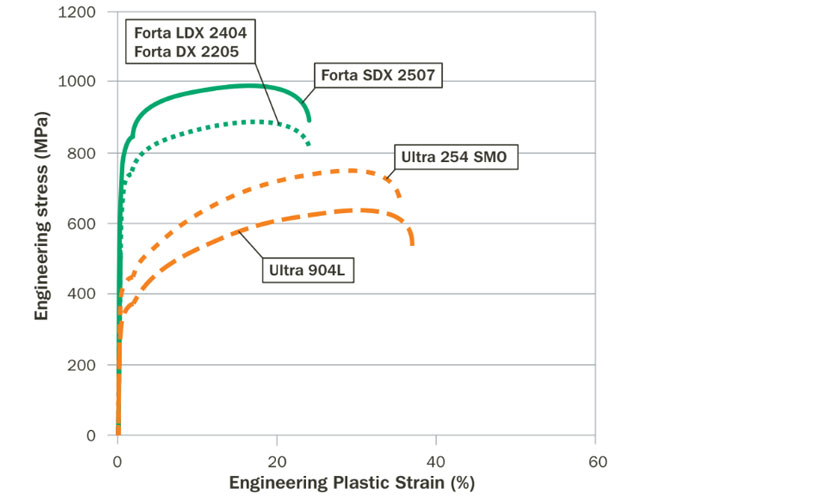

Duplex stainless steel is suitable for all forming processes used for stainless steel. The high yield strength compared to austenitic and ferritic stainless steel can however give differences in forming behavior. Depending on the chosen forming technique there could be consequences, such as increased springback. This point is particularly relevant to the forming of any high strength steel. Moreover, an excellent interplay between high yield strength, work hardening rate and elongation promote the duplex grades for light weight and cost-efficient applications with complex shapes. The impact of the high strength varies for different forming techniques. Common for all is that the estimated forming forces will be higher than for the corresponding austenitic and ferritic stainless steel grades. This effect will usually be lower than expected from just the increase in strength since the choice of duplex stainless steel is often associated with gauge reduction. It is important to consider that duplex stainless steel may also be more demanding on the tools and on the lubricant. This should also be noted when looking to down gauge.

Welding consumables

| name | EN | ASTM Type | UNS | Consumable ISO designation |

| 2507 | 1.4410 | 2507 | S32750 | 25 9 4 NL |

General characteristics

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2507 | 1.4410 | 2507 | S32750 | 43 | 20 | 550 | D | 0.02 | 25.0 | 7.0 | 4.0 | 0.27 |

Product

Quick contact

Get Solution

Organically grow the holistic world view of disruptive innovation via workplace diversity

Contact Us