- Chintamani Stainless Inc, 132, T.P. Streets, 6th Kumbharwada Lane, Mumbai- 400004, India

- Trophy Winning

- Ceritified ( ISO 9005-2010 )

Duplex Fittings

Chintamani Stainless Inc is ISO 9001:2008 certified manufacturer, supplier and exporter of Duplex fitings in India and worldwide. Duplex Steel fitings made by Fe-Ni-Cr alloys consisting of ferritic-austenitic microstructure at room temperature. Super Duplex Steel Plates exhibit greater toughness and better weldability than ferritic stainless steel. ASTM A240 Duplex Steel fitings has better corrosion resistance and higher strength than austenitic stainless steel fitings.

Duplex Steel Fittings are used in piping systems to connect pipes together. The fittings range in type,

size and dimensions. Chintamani Stainless Incs is a leading supplier and manufacturer of the Duplex SS

Fittings. The duplexs steel is special in that it has austenitic and ferritic steel phases in its

metallurgic microstructure. This allows for the fitting to withstand corrosion and to have strength.

There are different types of Duplex Pipe Fittings such as elbows, bends, unions, couplings, crosses and

tees. All these fitting are used in different application requirements.

There are different grades of duplexs steel based on the material composition. The Duplex 2205 Pipe

Fittings are the most used of duplexs in terms of the grade. The material is cost effective and has

optimum pressure, temperature and strength capabilities compared to the other duplexs steel grades.

There are lean duplexs and super duplexs grades of fitting in addition to the standard duplexs ones. The

ASTM A815 Duplex Fittings belong to a specification that covers duplexs and super duplexs grades of

fitting that are used in pulp and paper industry, bleaching equipment and other high temperature

services.

The Duplex stainless steel pipe fittings are also used in a variety of other fitting. The applications

include sea water, marine and other crucial industrial applications. The Duplex Steel S31803 Pipe

Fittings can come in different sizes based on the standards. The usual nominal bore sizes are from ½

inches through 48 inches. Duplex Steel 32205 Fittings manufacturer in india have good high toxic resistance.

Please feel free to contact us for more information on the UNS S32205 duplex fittings and their prices.

Duplex Steel UNS S31803 Buttweld Fittings are piping components made from Duplex Stainless Steel UNS

S31803, a dual-phase stainless steel alloy. These fittings are designed to connect or join sections of

piping together in a leak-free and secure manner.

Duplex Steel UNS S31803 offers unique properties compared to other stainless steel grades for buttweld

fittings. It has higher strength, hardness, and wear resistance compared to austenitic stainless steels

like 304 and 316. However, it exhibits lower corrosion resistance in aggressive environments compared to

these grades. The choice of stainless steel grade depends on the specific application requirements,

considering factors such as corrosion resistance, strength, and operating conditions.

A fitting is used to change the direction of the pipe. The simplest way to do it is to bend the pipe. However, it will stretch and thin out the outer walls of the pipe. It will also thicken the inner wall of the pipe. 2205 duplex stainless steel fittings are renowned for having austenitic and ferritic microstructures. They display the properties of both classes. Improved localized corrosion resistance is displayed by ASME SA815 Duplex Steel Butt Weld Pipe Fittings when compared to 316 and 317 grades.

Ordinary steel fittings are sensitive to chloride stress corrosion cracking. However, ASME SA815

Duplex Pipe Reducers are better as they restrain deformities and avoid corrosion cracking

even under high temperatures. UNS S31803 Duplex Steel Tee is said to have amazing toxic

resistance and elasticity due to which they are used in the gas desulfurization

industry. WERKSTOFF NR. 1.4462 End Cap have high resistance to intergranular corrosion

and are therefore used in terminating connections.

Duplex S31803 Stainless Steel Buttweld Fittings are used in desalination, Boiler manufacturers, and brewing tanks. They are usually lower in cost and have a lower percentage of alloying elements. They are available in ASTM A 815. A812, and ASME SA 815, SA 812 specifications. We at Victor Steel provide Duplex 2205 Pipe Fittings as per the specific requirements of our customers in various sizes and with different pressure ratings. Customer satisfaction is our top priority. Also, we are one of the few manufacturers in India that can weld, form, and bend these duplex stainless steel fittings in different sizes and shapes.

Specification

| Specifications | ASTM A815 and ASME SA815 |

|---|---|

| Size Range | Welded Fittings: 1/2 – 48 Inch Seamless Fittings: 1/2 – 10 Inch |

| Type | DN15 to DN1200 |

| Connection | Welding |

| Radius of bending | 10D, 2D, 3D, 1D, 8D, 5D, 6D, |

| Manufacturing process | Forge, Cast, Press, Push |

| Thickness | SCH80, XS, STD, XXS, SCH100, SCH30, SCH20, SCH160, SCH60, SCH40, SCH120, SCH140, SCH10 |

| Pressure Ratings | 2000#, 6000#, 150#, 3000#, 9000# |

| End Connections |

Socket weld / Threaded |

| Duplex 2205 Pipe Fittings manufacturer | 90º Elbows, Tee, Pipe Cap, 45º Elbows, Crosses, Stub End, Pipe Bend, Reducers |

| Dimensions | ASME B16.28, ASME/ANSI B16.9, BS4504, MSS-SP-43, BS1560, BS10 |

| Elbows | Angle = 2D, 3D, 1.5D, 5D, 2.5D, 1D, 6D, 4D, 7D-40D Standard = JISB2312, 22.5 deg, DIN2605, JISB2313, 30deg, ASME B16.9, MSS SP-75, 180 deg, 45 deg, JISB2311 BS, 90 deg, GB ISO |

| Test Certificates | Raw Materials Certificate EN 10204/3.1B Third Party Inspection Report, etc |

| Origin & Mills | USA, Japanese, Indian, Korean, European, Russian, Ukraine, |

Equivalent of ASTM A815 DSS Pipe Elbow

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex 2205 | 1.4462 | S31803 / S32205 |

Duplex Steel Pipe Bend Pressure Ratings

| NPS (inch) |

Pipe Sch. | Wall Thk. (in) |

OD (inch) |

Temperature | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | 500 | ||||||||

| Allowable Stress (Pressure Rating) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | ||||||||

| 1" | 40 | 0.133 | 1.315 | 2205 | 2205 | 2205 | 2047 | 1902 | ||||

| 80 | 0.179 | 1.315 | 3061 | 3061 | 3061 | 2841 | 2640 | |||||

| 160 | 0.250 | 1.315 | 4493 | 4493 | 4493 | 4170 | 3874 | |||||

| 1 1/2" | 40 | 0.145 | 1.900 | 1629 | 1629 | 1629 | 1512 | 1404 | ||||

| 80 | 0.200 | 1.900 | 2303 | 2303 | 2303 | 2138 | 1986 | |||||

| 160 | 0.281 | 1.900 | 3362 | 3362 | 3362 | 3120 | 2899 | |||||

| 2" | 40 | 0.154 | 2.375 | 1371 | 1371 | 1371 | 1272 | 1182 | ||||

| 80 | 0.218 | 2.375 | 1985 | 1985 | 1985 | 1843 | 1712 | |||||

| 160 | 0.344 | 2.375 | 3283 | 3283 | 3283 | 3047 | 2831 | |||||

| 3" | 40 | 0.216 | 3.500 | 1301 | 1301 | 1301 | 1208 | 1122 | ||||

| 80 | 0.300 | 3.500 | 1844 | 1844 | 1844 | 1712 | 1590 | |||||

| 160 | 0.438 | 3.500 | 2787 | 2787 | 2787 | 2587 | 2403 | |||||

| 4" | 40 | 0.237 | 4.500 | 1102 | 1102 | 1102 | 1023 | 950 | ||||

| 80 | 0.337 | 4.500 | 1596 | 1596 | 1596 | 1482 | 1377 | |||||

| 160 | 0.531 | 4.500 | 2611 | 2611 | 2611 | 2424 | 2552 | |||||

| 5" | 40 | 0.258 | 5.563 | 965 | 965 | 965 | 896 | 832 | ||||

| 80 | 0.375 | 5.563 | 1428 | 1428 | 1428 | 1325 | 1231 | |||||

| 160 | 0.625 | 5.563 | 2474 | 2474 | 2474 | 2296 | 2133 | |||||

| 6" | 40 | 0.280 | 6.625 | 877 | 877 | 877 | 814 | 756 | ||||

| 80 | 0.432 | 6.625 | 1379 | 1379 | 1379 | 1280 | 1189 | |||||

| 160 | 0.719 | 6.625 | 2382 | 2382 | 2382 | 2211 | 2054 | |||||

| 8" | 40 | 0.322 | 8.625 | 771 | 771 | 771 | 716 | 665 | ||||

| 80 | 0.500 | 8.625 | 1218 | 1218 | 1218 | 1131 | 1050 | |||||

| 160 | 0.906 | 8.625 | 2298 | 2298 | 2298 | 2133 | 1982 | |||||

| 10" | 40 | 0.365 | 10.750 | 699 | 699 | 699 | 649 | 603 | ||||

| 80 | 0.594 | 10.750 | 1159 | 1159 | 1159 | 1075 | 999 | |||||

| 160 | 1.125 | 10.750 | 2289 | 2289 | 2289 | 2124 | 1974 | |||||

EQUIVALENT GRADE OF DUPLEX STEEL S31803 / S32205 PIPE FITTING

| STANDARD | UNS | WNR. |

| Duplex 2205 | S31803/S32205 | 1.4462 |

DUPLEX STEEL UNS S32205 THREADED / SCREWED FITTINGS TOLERANCE

| UNS S32205 Pipe Fittings Tolerance | 90 Deg And 45 Deg Elbows And Pipe Tee |

Reducer (Concentric/ Eccentric) & Lap Joint Stub End (Long / Short) |

Pipe End Caps | |||

| Normal Pipe Size (NPS) Of ASME B16.9 | O. (Outside) D. (Daimeter) at Bevel |

I. (Inside) D.(Daimeter) at End |

Wall Thickness Of T | Center-to-End Dimension A ,C ,B |

Over-all Length Of H |

Over-all Length Of F |

| 1/2 to 2-1/2 | +0.06 | Not less than 87.5% of nominal thickness |

+/- 0.06 | +/- 0.06 | +/- 0.12 | |

| -0.03 | ||||||

| 3 to 3-1/2 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 4 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 5 to 8 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.25 | |

| 10 to 18 | +0.16 | +/- 0.12 | +/- 0.09 | +/- 0.09 | +/- 0.25 | |

| -0.12 | ||||||

| 20 to 24 | +0.25 | +/- 0.19 | +/- 0.09 | +/- 0.09 | +/- 0.25 | |

| -0.19 | ||||||

| 26 to 30 | +0.25 | +/- 0.19 | +/- 0.12 | +/- 0.19 | +/- 0.38 | |

| -0.19 | ||||||

| 32 to 48 | +0.25 | +/- 0.19 | +/- 0.19 | +/- 0.19 | +/- 0.38 | |

| -0.19 | ||||||

CHEMICAL COMPOSITION

| Grade | Carbon | Manganese | Silicon | Phosphorus | Sulfur | Chromium | Molybdenum | Nickel | Nitrogen | Iron |

| S31803 | 0.030 Maximum | 2.00 Maximum | 1.00 Maximum | 0.030 Maximum | 0.020 Maximum | 22.0 To 23.0 | 3.0 To 3.5 | 4.50 To 6.50 | 0.14 To 0.20 | 63.72 Minimum |

| S32205 | 0.030 Maximum | 2.00 Maximum | 1.00 Maximum | 0.030 Maximum | 0.020 Maximum | 21.0 To 23.0 | 2.50 – 3.50 | 4.50 To 6.50 | 0.8 To 0.20 | 63.54 Minimum |

MECHANICAL PROPERTIES

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S31803 / S32205 | 7.805 | 0.285 | 1420 – 1465 | 2588 – 2669 |

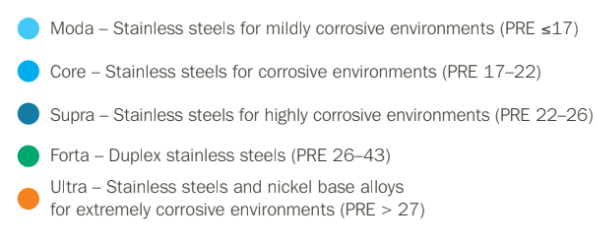

General characteristics

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2205 | 1.4462 | 2205 | S32205 | 35 | 20 | 500 | D | 0.02 | 22.4 | 5.7 | 3.1 | 0.17 |

| 2205 stainless steel grades | Industry Specifications | UNS |

Duplex 2205 2205 (EN 1.4462/UNS S32205 & S31803) |

• Cargo tanks in chemical tankers • Pulp and paper industry applications such as digesters and process tanks • Oil and gas industry, typically tubular products, flanges, fittings and valves • Structural components in bridges |

• Cold rolled coil and sheet • Hot rolled coil and sheet • Quarto plate • Bar • Wire rod • Semi-finished (bloom, billet, ingot & slab) |

Performance

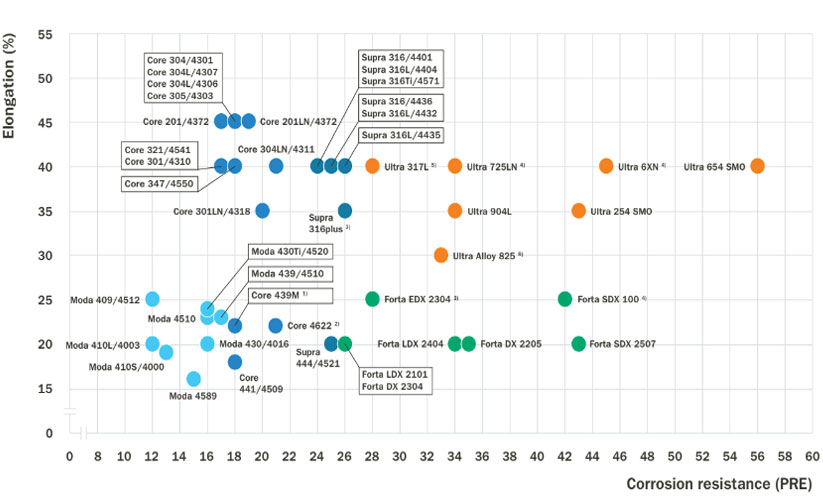

Elongation vs. corrosion resistance.

Elongation vs. Corrosion resistance

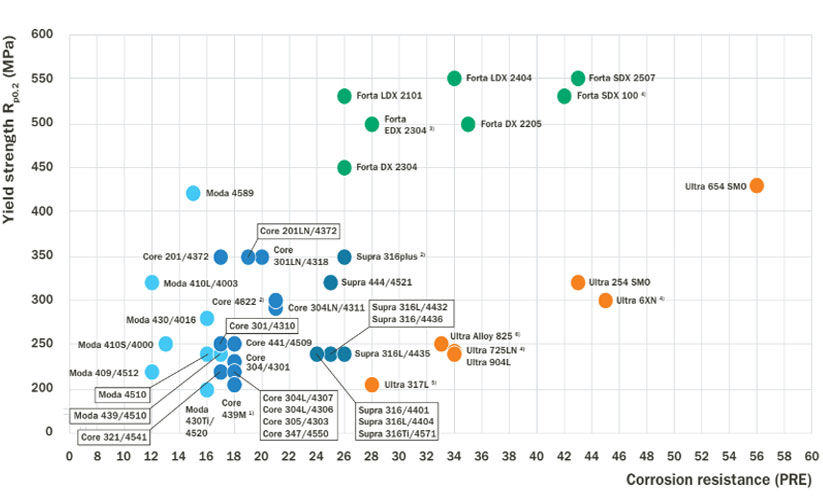

Strength vs. Corrosion resistance

Elongation vs. Corrosion resistance

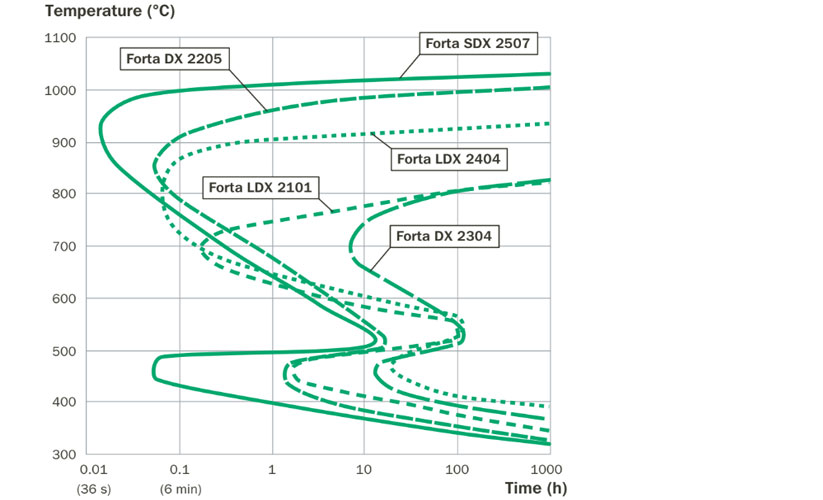

Duplex stainless steels, known for their high chromium content, provide excellent corrosion resistance, particularly in uniform corrosion environments with rates below 0.1 mm/year. Forta DX 2205 shows superior resistance to chloride-contaminated sulfuric acid compared to traditional stainless steels like Supra 316L/4404, approaching the performance of Ultra 904L. In dilute hydrochloric acid, Forta SDX 2507 and similar high-alloyed duplex steels are suitable, though localized corrosion risks exist around crevices even within safe usage limits.

PRE values for Forta Duplex grades and some austenitic grades

Steel designations |

PRE |

|||

| name | EN | ASTM Type |

UNS | |

| 2205 | 1.4462 | 2205 | S32205 | 35 |

Results from stress corrosion cracking immersion tests in chloride solutions

| name | ASTM G123 | ASTM G36 | ||

| 25% NaCl, pH 1.5, 106°C (b.p.), 1,000 h | 40% CaCl2, 100°C, 500 h | 45% MgCl2, 155°C (b.p.), 24 h | ||

| U-bend samples | 4-PB samples (90% of Rp0.2) | U-bend samples | ||

| 2205 | No SCC | No SCC | SCC | |

Mechanical properties according to EN 10088 and EN 10028

| EN | ASTM | Product form | Yield strength | Tensile | Elongation | Elongation | |

| name | UNS | Rp0.2[MPa] | strength | A[%] | A80[%] | ||

| Rm[MPa] | |||||||

| 2205 | 1.4462 | S32205 | Cold rolled coil (C) | 500 | 700–950 | 20 | 20 |

| Hot rolled coil (H) | 460 | 700–950 | 25 | 25 | |||

| Quarto plate (P) | 460 | 640–840 | 25 | 25 | |||

| Wire rod 1) | 510 | 750 | 35 | – | |||

| Bar | 450 | 650–880 | 25 | – |

Mechanical properties according to ASTM A240

| EN | ASTM | Product form | Yield | Yield | Tensile | Tensile | Elongation | |

| name | UNS | strength | strength | strength | strength | A50[%] | ||

| Rp0.2[MPa] | Rp0.2 [ksi] | Rm [MPa] | Rm [ksi] | |||||

| 2205 | 1.4462 | S32205 | Plate, sheet and strip | 450 | 65 | 655 | 95 | 25 |

| Wire rod 1) | 510 | 74 | 752 | 109 | – |

Mechanical properties at elevated temperatures, minimum yield strength according to EN 10028-7

| name | Strength | 100°C | 150°C | 200°C | 250°C | |

| 2205 | Yield strength | Rp0.2 [MPa] | 360 | 335 | 315 | 300 |

| Tensile strength | Rm [MPa] | 590 | 570 | 550 | 540 | |

Physical properties

Metric values according to EN 10088-1

| name | EN | ASTM Type | UNS | Density [kg/dm3] | Modulus of elasticity at 20°C [GPa] | Coefficient of thermal expansion 20–100°C [10-6/K] | Thermal conductivity at 20°C [W/(m x K)] | Thermal capacity at 20°C [J/(kg x K)] | Electrical resistivity at 20°C [Ω x mm2/m] |

| 2205 | 1.4462 | 2205 | S32205 | 7.8 | 200 | 13.0 | 15 | 500 | 0.8 |

Imperial values converted from Table 10

| name | Density [lbm/in3] | Modulus of elasticity [psi] | Coefficient of thermal expansion 68–212°F [μin / (in x °F)] | Thermal conductivity [Btu/(hr x ft x °F)] | Thermal capacity [Btu/(lbm x °F)] | Electrical resistivity [μΩ x in] |

| 2205 | 0.282 | 29 x 106 | 7.2 | 8.7 | 0.119 | 31.50 |

Fabrication

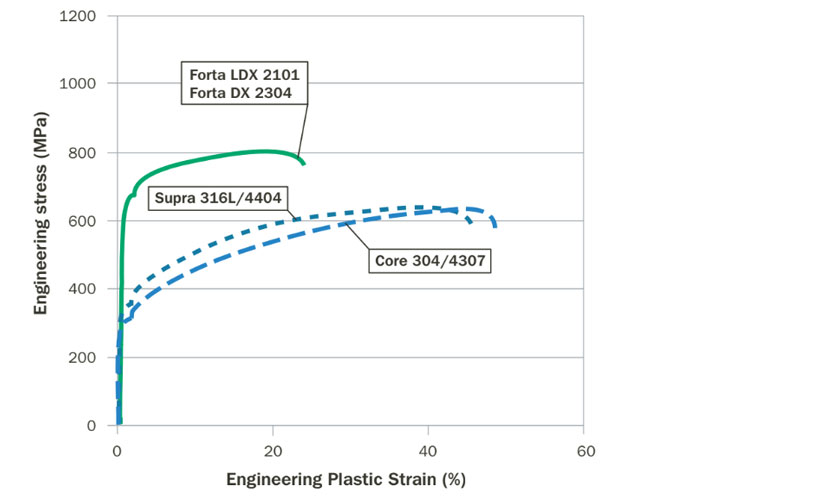

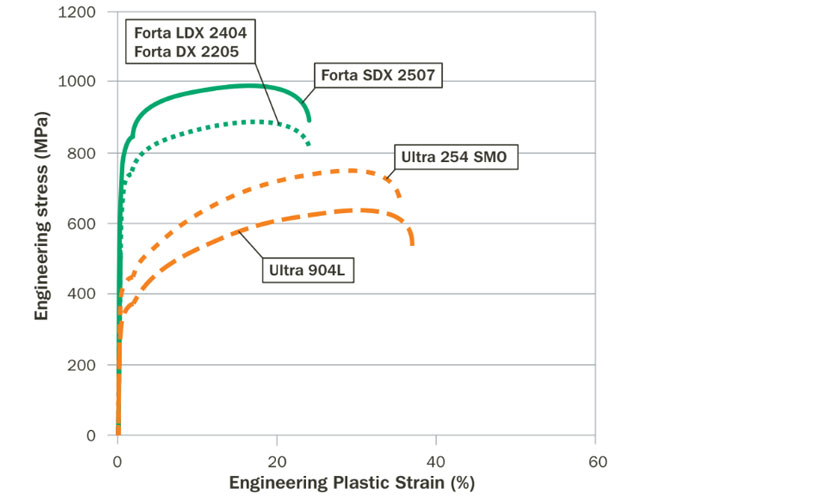

Duplex stainless steel is suitable for all forming processes used for stainless steel. The high yield strength compared to austenitic and ferritic stainless steel can however give differences in forming behavior. Depending on the chosen forming technique there could be consequences, such as increased springback. This point is particularly relevant to the forming of any high strength steel. Moreover, an excellent interplay between high yield strength, work hardening rate and elongation promote the duplex grades for light weight and cost-efficient applications with complex shapes. The impact of the high strength varies for different forming techniques. Common for all is that the estimated forming forces will be higher than for the corresponding austenitic and ferritic stainless steel grades. This effect will usually be lower than expected from just the increase in strength since the choice of duplex stainless steel is often associated with gauge reduction. It is important to consider that duplex stainless steel may also be more demanding on the tools and on the lubricant. This should also be noted when looking to down gauge.

Welding consumables

| name | EN | ASTM Type | UNS | Consumable ISO designation |

| 2205 | 1.4462 | 2205 | S32205 | 22 9 3 NL |

General characteristics

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2205 | 1.4462 | 2205 | S32205 | 35 | 20 | 500 | D | 0.02 | 22.4 | 5.7 | 3.1 | 0.17 |

Product

Quick contact

Get Solution

Organically grow the holistic world view of disruptive innovation via workplace diversity

Contact Us