- Chintamani Stainless Inc, 132, T.P. Streets, 6th Kumbharwada Lane, Mumbai- 400004, India

- Trophy Winning

- Ceritified ( ISO 9005-2010 )

Duplex Sheet Plate

Chintamani Stainless Inc is ISO 9001:2008 certified manufacturer, supplier and exporter of Duplex 2205/31803 plate stockists in india and worldwide. Duplex Steel Sheets made by Fe-Ni-Cr alloys

consisting of ferritic-austenitic microstructure at room temperature. Super Duplex Steel

Plates exhibit greater toughness and better weldability than ferritic stainless steel.

ASTM A240 Duplex Steel Plate has better corrosion resistance and higher strength than

austenitic stainless steel plates.

Duplex Plates are mostly used in chemical and petrochemical applications, in power

plants due to their high resistance to localized corrosion as well as to their high

strength and toughness. Duplex Steel Perforated Sheets applications should be limited to

temperatures below 600° F. Meanwhile, these Super Duplex Plates are also being offered

in different sizes and shapes to our customers. Duplex Coil is a combination of

molybdenum, chromium, and nitrogen conveys the good resistance of 2205 to chloride

pitting and crevice corrosion.

Duplex 2205/UNS S3205 / UNS31803 / EN 1.4462

UNS S31803/2205 is a duplex grade with a ferritic-austenitic microstructure. The alloy

consists of around 40-50% ferrite in the annealed condition. The duplex microstructure

has the high strength of the ferritic grades whilst retaining the corrosion resistance

of the austenitic grades. It is not uncommon to see the metal used as a practical

solution to chloride-induced stress cracking, which is the achilles’ heel of stainless

steel.

It has superior resistance to chloride pitting and crevice corrosion as compared to 317L

stainless steel. The alloy has outstanding corrosion resistance to seawater and most

concentrations of sulphuric acid. In addition, it is also resistant to sulphide stress

corrosion cracking (sour-gas environments).

The high quality and therefore performance of UNS S32205 is widely attributed to the

high levels of chromium present as well as nitrogen and molybdenum.

Compared to ordinary austenitic steel, Alloy 2205 - Duplex Stainless Plate is a stronger austenite and ferrite steel. at comparison to regular austenitic steels, duplex stainless steels,

such as ASTM A240 Duplex Steel 2205 Plate Material, are significantly more resistant to

stress corrosion cracking and frequently retain good weldability at their thickest

regions. 3% molybdenum, 22% chromium, 5-6% nickel, and high-stress resistance features

characterize ASTM A240 Duplex 2205 Sheet, an alloyed stainless steel plate with

exceptional oxidation resistance.

316L or 317L austenite stainless steel is less resistant to pitting and crevice

corrosion. Nearly all of the corrosion resistance qualities are offered by alloy 2205

steel plate. In addition, it exhibits stronger heat expansion, corrosion, oxidation, and

thermal conductivity than austenitic ones. DS Plates were created to address typical

issues with 300 grade stainless steel corrosion. About 40–50% ferrite is produced by

Duplex 2205 Cold Rolled Plate when it is annealed.Duplex alloys have the advantage of

combining the advantageous characteristics of both ferritic and Austin alloys, namely

ease of manufacture and corrosion resistance. The ASTM A240 Duplex 2205 Perforated Sheet

should only be used at temperatures lower than 600 °F. High temperatures over an

extended period of time will stainlessly inflate 2205

Duplex stainless steels are work-hardenable alloys with exceptional resistance to corrosion. They have a blend of ferrite and austenite phases in their microstructures. Duplex stainless steels thus exhibit qualities shared by ferritic and austenitic stainless steels. In comparison to pure austenitic and pure ferritic grades, this mix of characteristics may entail some compromise. Most of the time, duplex stainless steels are more durable than ferritic stainless steels. In certain instances, the strengths of duplex stainless steels can surpass those of austenitic stainless steels by twofold. Although duplex stainless steels are thought to be resistant to stress corrosion cracking, ferritic stainless steels are more resistant to this type of assault.

Specification Of Duplex Stainless Steel

| Property | Value |

|---|---|

| Material | Duplex 2205 (UNS S31803/UNS S32205/EN 1.4462) |

| Standard | ASTM A240, EN 10028-7, ASME SA-240 |

| Grade Designations | UNS S31803, UNS S32205, EN 1.4462 |

| Thickness Range | 0.8 mm to 100 mm |

| Width Range | 1000 mm to 2500 mm (as per customer requirement) |

| Length Range | 2000 mm to 12000 mm |

| Surface Finish | No.1, 2B, 2D, 2R, HR. (as per customer requirement) |

| Hardness (Brinell) | 293 max |

| Tensile Strength (MPa) | 620 min |

| Yield Strength (0.2% Offset) | 450 min |

| Elongation (%) | 25 min |

| Density | 7.8 g/cm^3 |

| Thermal Conductivity | 19 W/(m·K) at 100°C |

| Thermal Expansion Coefficient | 13.7 µm/m°C (20-100°C) |

| Specific Heat Capacity | 475 J/(kg·K) at 0-100°C |

| Modulus of Elasticity | 200 GPa |

| Electrical Resistivity | 850 µΩ·cm |

| Weldability | Excellent |

| Machinability | Fair to Good |

| Corrosion Resistance | Excellent, especially in chloride environments |

| Applications | Chemical processing, oil and gas exploration, desalination plants, marine applications, etc. |

Duplex Stainless Steel Sheet Plate ASTM Specifications

| Duplex | ASTM A240 ASME SA240 S31803/S32205 |

| Super Duplex | ASTM A240 ASME SA240 S32750/S32760 |

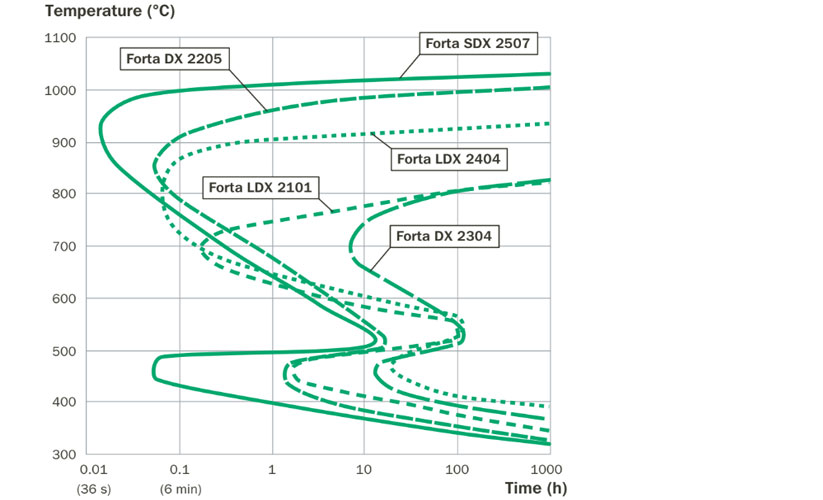

Duplex Stainless Steel Temperature Limit

Temperature Rating: 1020-1100°C/ 1868-2012°F

Duplex and Super Duplex Stainless Steel Metric Dimension

| SURFACE FINISH | THICKNESS (MM) | WIDTH (MM) |

|---|---|---|

| 2B – Cold rolled, heat treated, pickled, skin passed | 0.25–8.0 | max. 2032 |

| 2D – Cold rolled, heat treated, pickled | 0.4–6.35 | max. 1524 |

| 2E – Cold rolled, heat treated, mechanically descaled | 0.4–8.0 | max. 2032 |

| 2R – Cold rolled, bright annealed | 0.25–3.5 | max. 1524 |

| 2H – Work hardened | 0.4–6.35 | max. 1524 |

| Polished, brushed | 0.5–4.0 | max. 1524 |

Duplex 2205 Specification

- ASTM A 182, A 240, A 276, A 789, A 790, A 815

- UNS S31803, S32205

- NACE MR0175

| 2205 stainless steel grades | Industry Specifications | UNS |

| Duplex 2205 22Cr |

ASME SA-182 (F60), SA-240, SA-798, SA-790, SA-815 ASTM A182 (F60), A240, A276, A479, A480, A798, A790, A815, A928, A988 SAE J405 |

UNS S32205 |

| Duplex 2205 22Cr |

ASME SA-182 (F51), SA-240, SA-798, SA-790, SA-815 ASTM A182 (F51),A240, A276, A479, A789, A790, A815, A928, A988 SAE J405 |

UNS S31803 |

| Grade | 2205 Seamless and welded tube and pipe | 2205 Plate, sheet and strip | 2205 Bar | 2205 Forgings | 2205 Flanges | 2205 Fittings |

| Duplex 2205 / Avesta 2205 / Saf 2205 Duplex Stainless Steel | ASTM A789; A790 NFA 49-217 |

ASTM A240 EN 10088-2 |

ASTM A276 ASTM A479 EN 10088-3 |

ASTM A182 | ASTM A182 | ASTM A182, ASTM A815 |

| Duplex Stainless Steel Grade 2205 | Alloy 2205 Uns Number | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

Duplex 2205 / Avesta 2205 |

S31803 / S32205 |

318S13 |

- |

1.4462 |

X2CrNiMoN22-5-3 |

2377 |

SUS 329J3L |

- Resistance to crevice corrosion & chloride pitting

- High resistance to chloride stress corrosion cracking

- Good sulfide stress corrosion resistance

- Good general corrosion resistance

- Good workability and weldability

- High Strength

| Duplex Alloy 2205 | UNS S31803, UNS S32205 |

Grade |

Tensile Str |

Yield Strength |

Elongation |

Hardness |

|

Rockwell C (HR C) |

Brinell (HB) |

||||

2205 |

621 |

448 |

25 |

31 max |

293 max |

Duplex 2205/UNS S3205 / UNS31803 / EN 1.4462 Chemical Composition

| Cr | Ni | Mo | C | N | Mn | Si | P | S | Fe |

| 22.0-23.0 | 4.50-6.50 | 3.00-3.50 | .030 Max | 0.14-0.20 | 2.00 Max | 1.00 Max | .030 Max | .020 Max | Balance |

2205 Stainless Steel grades are used for many industries, check below 2205 Stainless Steel Applications & uses:

| Chemical Process | Pharmaceutical | Geothermal | Petrochemical | Sea Water | Oil & Gas |

| Biomass | Mining | Utilities | Nuclear Power | Solar Power | Storage tanks |

| Water Desalination | Reinforcement bars | Building and construction | LNG (Liquefied Natural Gas) | Water piping |

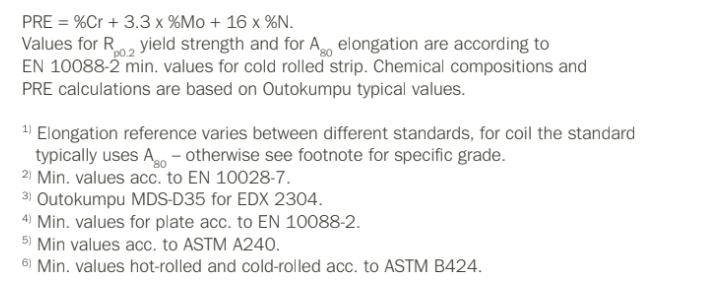

General characteristics

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2205 | 1.4462 | 2205 | S32205 | 35 | 20 | 500 | D | 0.02 | 22.4 | 5.7 | 3.1 | 0.17 |

| 2205 stainless steel grades | Industry Specifications | UNS |

Duplex 2205 2205 (EN 1.4462/UNS S32205 & S31803) |

• Cargo tanks in chemical tankers • Pulp and paper industry applications such as digesters and process tanks • Oil and gas industry, typically tubular products, flanges, fittings and valves • Structural components in bridges |

• Cold rolled coil and sheet • Hot rolled coil and sheet • Quarto plate • Bar • Wire rod • Semi-finished (bloom, billet, ingot & slab) |

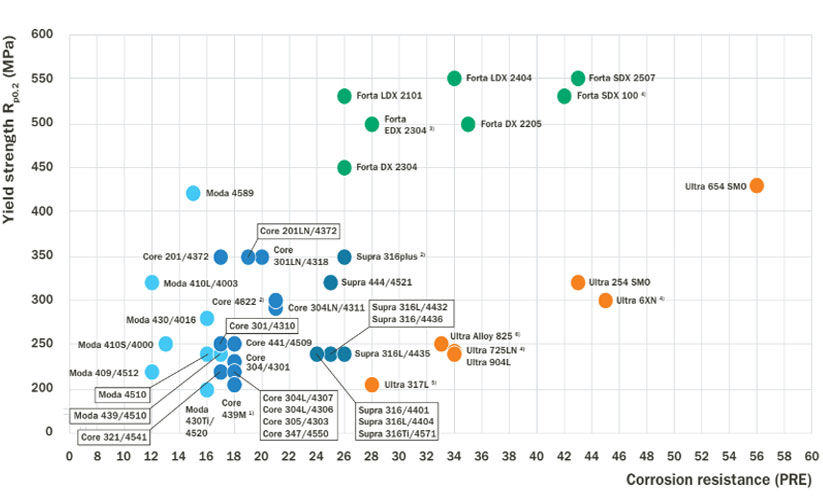

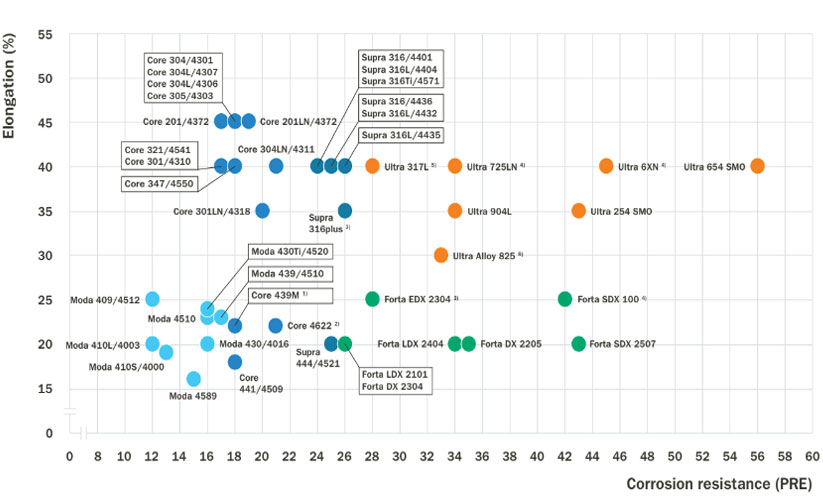

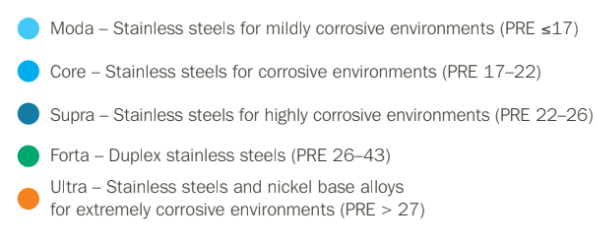

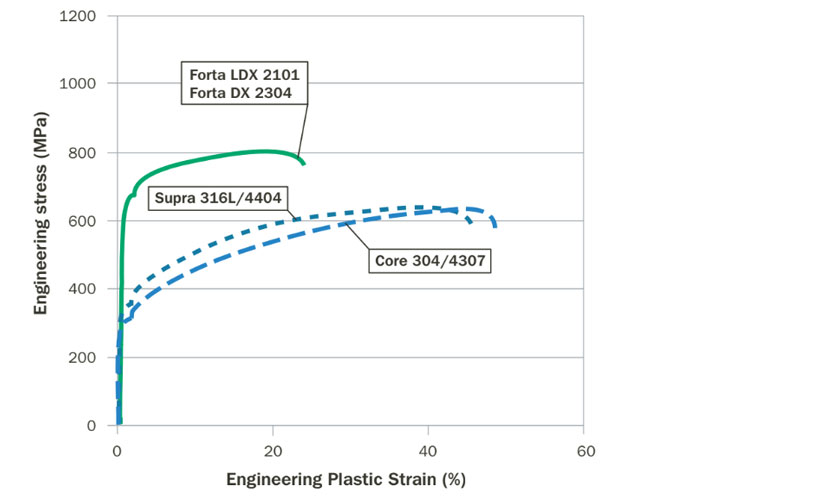

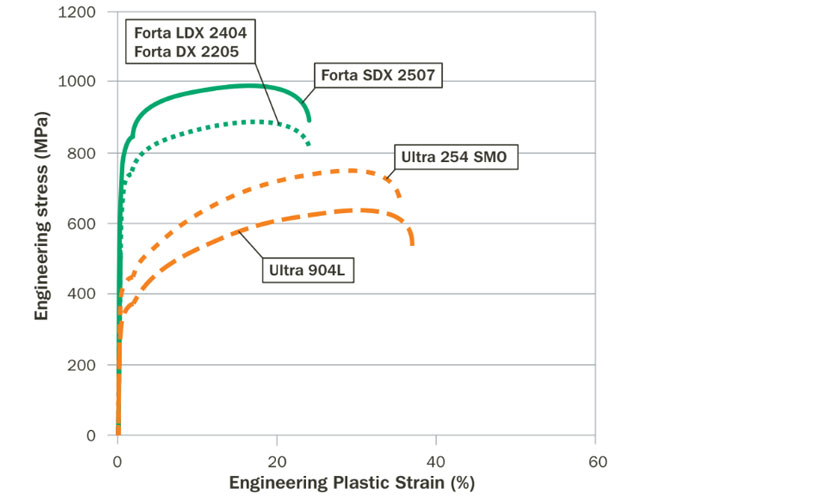

Performance

Elongation vs. corrosion resistance.

Elongation vs. Corrosion resistance

Strength vs. Corrosion resistance

Elongation vs. Corrosion resistance

Duplex stainless steels, known for their high chromium content, provide excellent corrosion resistance, particularly in uniform corrosion environments with rates below 0.1 mm/year. Forta DX 2205 shows superior resistance to chloride-contaminated sulfuric acid compared to traditional stainless steels like Supra 316L/4404, approaching the performance of Ultra 904L. In dilute hydrochloric acid, Forta SDX 2507 and similar high-alloyed duplex steels are suitable, though localized corrosion risks exist around crevices even within safe usage limits.

PRE values for Forta Duplex grades and some austenitic grades

Steel designations |

PRE |

|||

| name | EN | ASTM Type |

UNS | |

| 2205 | 1.4462 | 2205 | S32205 | 35 |

Results from stress corrosion cracking immersion tests in chloride solutions

| name | ASTM G123 | ASTM G36 | ||

| 25% NaCl, pH 1.5, 106°C (b.p.), 1,000 h | 40% CaCl2, 100°C, 500 h | 45% MgCl2, 155°C (b.p.), 24 h | ||

| U-bend samples | 4-PB samples (90% of Rp0.2) | U-bend samples | ||

| 2205 | No SCC | No SCC | SCC | |

Mechanical properties according to EN 10088 and EN 10028

| EN | ASTM | Product form | Yield strength | Tensile | Elongation | Elongation | |

| name | UNS | Rp0.2[MPa] | strength | A[%] | A80[%] | ||

| Rm[MPa] | |||||||

| 2205 | 1.4462 | S32205 | Cold rolled coil (C) | 500 | 700–950 | 20 | 20 |

| Hot rolled coil (H) | 460 | 700–950 | 25 | 25 | |||

| Quarto plate (P) | 460 | 640–840 | 25 | 25 | |||

| Wire rod 1) | 510 | 750 | 35 | – | |||

| Bar | 450 | 650–880 | 25 | – |

Mechanical properties according to ASTM A240

| EN | ASTM | Product form | Yield | Yield | Tensile | Tensile | Elongation | |

| name | UNS | strength | strength | strength | strength | A50[%] | ||

| Rp0.2[MPa] | Rp0.2 [ksi] | Rm [MPa] | Rm [ksi] | |||||

| 2205 | 1.4462 | S32205 | Plate, sheet and strip | 450 | 65 | 655 | 95 | 25 |

| Wire rod 1) | 510 | 74 | 752 | 109 | – |

Mechanical properties at elevated temperatures, minimum yield strength according to EN 10028-7

| name | Strength | 100°C | 150°C | 200°C | 250°C | |

| 2205 | Yield strength | Rp0.2 [MPa] | 360 | 335 | 315 | 300 |

| Tensile strength | Rm [MPa] | 590 | 570 | 550 | 540 | |

Physical properties

Metric values according to EN 10088-1

| name | EN | ASTM Type | UNS | Density [kg/dm3] | Modulus of elasticity at 20°C [GPa] | Coefficient of thermal expansion 20–100°C [10-6/K] | Thermal conductivity at 20°C [W/(m x K)] | Thermal capacity at 20°C [J/(kg x K)] | Electrical resistivity at 20°C [Ω x mm2/m] |

| 2205 | 1.4462 | 2205 | S32205 | 7.8 | 200 | 13.0 | 15 | 500 | 0.8 |

Imperial values converted from Table 10

| name | Density [lbm/in3] | Modulus of elasticity [psi] | Coefficient of thermal expansion 68–212°F [μin / (in x °F)] | Thermal conductivity [Btu/(hr x ft x °F)] | Thermal capacity [Btu/(lbm x °F)] | Electrical resistivity [μΩ x in] |

| 2205 | 0.282 | 29 x 106 | 7.2 | 8.7 | 0.119 | 31.50 |

Fabrication

Duplex stainless steel is suitable for all forming processes used for stainless steel. The high yield strength compared to austenitic and ferritic stainless steel can however give differences in forming behavior. Depending on the chosen forming technique there could be consequences, such as increased springback. This point is particularly relevant to the forming of any high strength steel. Moreover, an excellent interplay between high yield strength, work hardening rate and elongation promote the duplex grades for light weight and cost-efficient applications with complex shapes. The impact of the high strength varies for different forming techniques. Common for all is that the estimated forming forces will be higher than for the corresponding austenitic and ferritic stainless steel grades. This effect will usually be lower than expected from just the increase in strength since the choice of duplex stainless steel is often associated with gauge reduction. It is important to consider that duplex stainless steel may also be more demanding on the tools and on the lubricant. This should also be noted when looking to down gauge.

Welding consumables

| name | EN | ASTM Type | UNS | Consumable ISO designation |

| 2205 | 1.4462 | 2205 | S32205 | 22 9 3 NL |

General characteristics

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2205 | 1.4462 | 2205 | S32205 | 35 | 20 | 500 | D | 0.02 | 22.4 | 5.7 | 3.1 | 0.17 |

Product

Quick contact

Get Solution

Organically grow the holistic world view of disruptive innovation via workplace diversity

Contact Us