- Chintamani Stainless Inc, 132, T.P. Streets, 6th Kumbharwada Lane, Mumbai- 400004, India

- Trophy Winning

- Ceritified ( ISO 9005-2010 )

Super Duplex Round Bar

Chintamani Stainless Inc is ISO 9001:2008 certified manufacturer, supplier and exporter of Super Duplex Steel Round Bar in India and worldwide.The S32760 has the addition of tungsten and copper in the composition which makes it much resistant to chloride ion rich environments. Our SAF 2507 Round Bar has a different mixture; 25% chromium, 7% nickel and 4% molybdenum. The nitrogen and manganese content make the material resistant to most organic acids and make it stronger. There are super duplex grade bars as well. Our Super Duplex S32750 Flat Bar can be used for excellent yield strength and corrosion resistant properties. There are different specifications such as the Super Duplex Stainless Steel WERKSTOFF NR. 1.4410 Rod which can be used in high temperature applications as well. The use of super duplex bars is seen in the aerospace industries, food processing industries, chemical industries, power generation plants and in sea water applications. The bars can also be used in structural applications. The Super Duplex 2507 Hex Bar for example can carry much weight because of the shape and is used in the construction industry. While the black bars are cost effective, the ASME SA276 2507 Duplex Stainless Steel Bright Bar is used in applications that have decorative values.

Specification

| Grade | Super Super Duplex Round Bar |

|---|---|

| Super Duplex Square bar size | 4 to 100mm |

| SS Super Duplex Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Super Duplex Steel Hex Bar size | 2-100mm A/F |

| Super Duplex Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| SS Super Duplex Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Super Duplex Steel Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Super Duplex Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| SS Super Duplex Section | 3.0 to 12.0mm thickness |

| Super Duplex Steel Round bar size | Diameter: 3-~800mm |

| Super Duplex Billet Size | 1/2" to 495mm Diameter |

| SS Super Super Duplex Round Bar Standard Dimensions | Diameter / Height: Super Duplex Rod and Bar Sizes : 0.5 inches / 0.625 inches / 0.75 inches / 0.875 inches / 1.0 inches / 1.125 inches / 1.25 inches / 1.375 inches / 1.5 inches / 1.75 inches / 2.0 inches / 2.25 inches / 2.5 inches / 2.75 inches / 3.0 inches / 3.25 inches / 3.5 inches / 3.75 inches / 4.0 inches / 4.25 inches / 4.5 inches / 5.0 inches / 5.25 inches / 5.5 inches / 6.0 inches / 7.0 inches / 8.0 inches / 9.0 inches. |

| Super Duplex Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| SS Super Duplex Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Super Duplex Steel Technique | Super Duplex Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Super Duplex Condition | Hardened & tempered, annealed |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Form | Super Duplex Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square Bar, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

| Processing | Bar cutting to 650mm |

| Our Super Super Duplex Round Bar conforms to NACE MR0175/ISO 15156 | |

SUPER Super Duplex Round Bar SIZES

| Type | SIZES (mm) | SIZES (Inches) | ISO Tolerance |

|---|---|---|---|

| Cold Drawn and Ground | 10.00 – 75.00 | 5/6" – 2.50" | h8-h9-h10-h11 |

| Peeled and Polished | 40.00 – 150.00 | 1.50" – 6.00" | h11, h11-DIN 1013 |

| Peeled and Ground | 20.00 – 50.00 | 3/4″ – 2.00" | h9-h10-h11 |

| Cold Drawn and Polish | 3.00 – 75.00 | 1/8" – 3.00" | h8-h9-h10-h11 |

CHEMICAL COMPOSITION

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S32750/S32760 | 7.8 | 0.281 | 1350 | 2460 |

MECHANICAL PROPERTIES

| Grade | Mn | Si | P | C | S | Cr | Fe | Mo | Ni | N |

| S32750 | 1.20 max | 0.80 max | 0.035 max | 0.030 max | 0.020 max | 24.00 – 26.00 | 58.095 min | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 |

| S32760 | 1.00 max | 1.00 max | 0.030 max | 0.05 max | 0.010 max | 24.00 – 26.00 | 57.61 min | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 |

Super Duplex Stainless Steel Pipe Size Chart In Inches

| The sizes of 2507 Super Duplex Bars | |||||||

|---|---|---|---|---|---|---|---|

| Metric | US Bar | ASTM/ Canadian | Japanese | ||||

| Bar Size | Diam. (mm) | Bar Size | Diam. (Inch) | Bar Size | Diam. (mm2) | Bar Size | Diam. (mm) |

| 5 | 5 | #2 | 0.250 | 10M | 100 | 6 | 6 |

| 5.5 | 5.5 | #3 | 0.375 | 15M | 200 | 10 | 10 |

| 6 | 6 | #4 | 0.500 | 20M | 300 | 13 | 13 |

| 7 | 7 | #5 | 0.625 | 25M | 500 | 16 | 16 |

| 8 | 8 | #6 | 0.750 | 30M | 700 | 19 | 19 |

| 9 | 9 | #7 | 0.875 | 35M | 1000 | 22 | 22 |

| 10 | 10 | #8 | 1.000 | 45M | 1500 | 25 | 25 |

| 11 | 11 | #9 | 1.125 | 55M | 2500 | 29 | 29 |

| 12 | 12 | #10 | 1.250 | 32 | 32 | ||

| 14 | 14 | #11 | 1.375 | 35 | 35 | ||

| 16 | 16 | #12 | 1.500 | 38 | 38 | ||

| 18 | 18 | #13 | 1.625 | 41 | 41 | ||

| 20 | 20 | #14 | 1.750 | 44 | 44 | ||

| 22 | 22 | #15 | 1.875 | 48 | 48 | ||

| 25 | 25 | #16 | 2.000 | 51 | 51 | ||

| 28 | 28 | #18 | 2.250 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

General characteristics

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2507 | 1.4410 | 2507 | S32750 | 43 | 20 | 550 | D | 0.02 | 25.0 | 7.0 | 4.0 | 0.27 |

| 2205 stainless steel grades | Industry Specifications | UNS |

| Duplex 2507 2507 (EN 1.4410/UNS S32750) A super duplex product with higher corrosion resistance and mechanical strength than Forta DX 2205. Often used in extremely corrosive environments. |

• Desalination plants • Industrial piping • Scrubbers • Oil and gas industry, typically tubular products, flanges,fittings and valves • Deep-sea pipelines |

• Cold rolled coil and sheet • Hot rolled coil and sheet • Quarto plate • Bar • Wire rod • Semi-finished (bloom, billet, ingot & slab) |

| Duplex 32760 100 (EN 1.4501/UNS S32760) A super duplex product with higher corrosion resistance and mechanical strength than Forta DX 2205. Often used in extremely corrosive environments. |

• Desalination plants • Industrial piping • Scrubbers • Oil and gas industry, typically tubular products, flanges, fittings and valves • Deep-sea pipelines |

• Cold rolled coil and sheet • Hot rolled coil and sheet • Quarto plate • Bar • Wire rod • Semi-finished (bloom, billet, ingot & slab) |

Performance

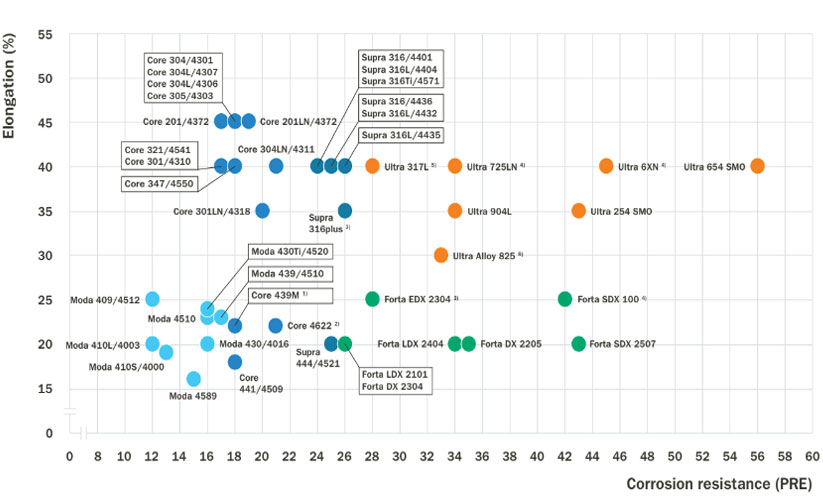

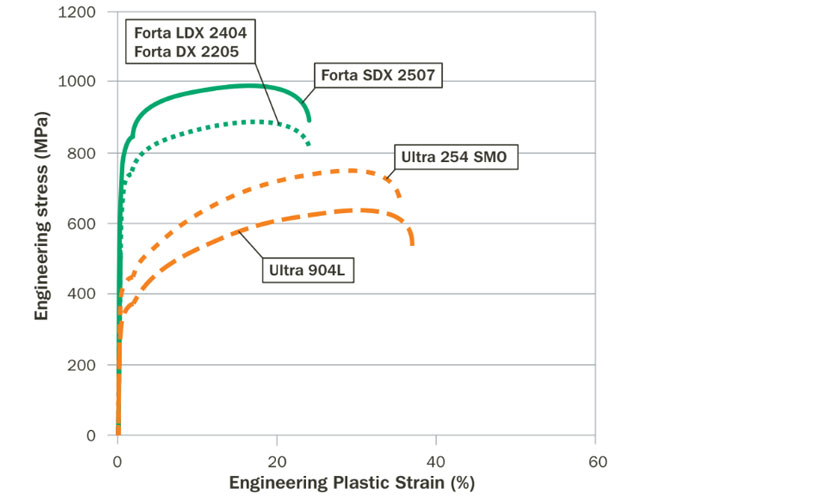

Elongation vs. corrosion resistance.

Elongation vs. Corrosion resistance

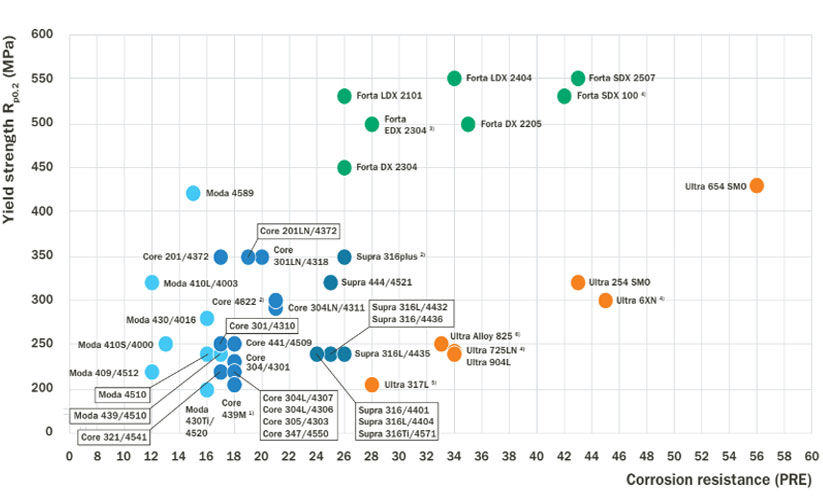

Strength vs. Corrosion resistance

Elongation vs. Corrosion resistance

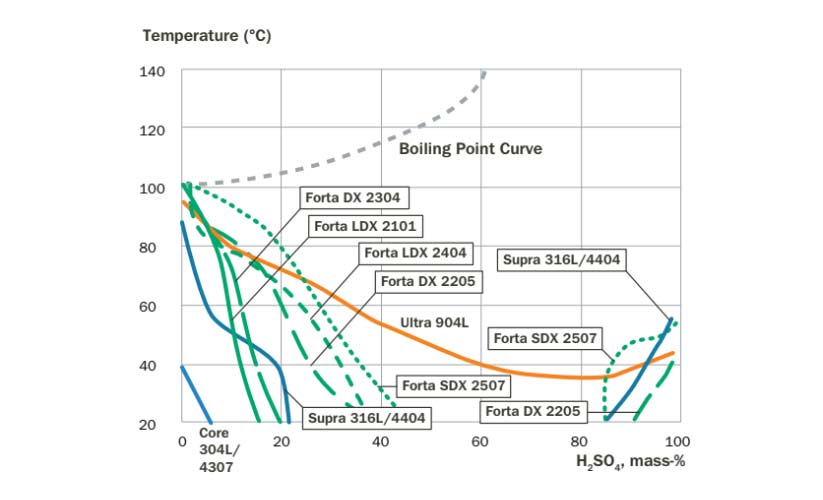

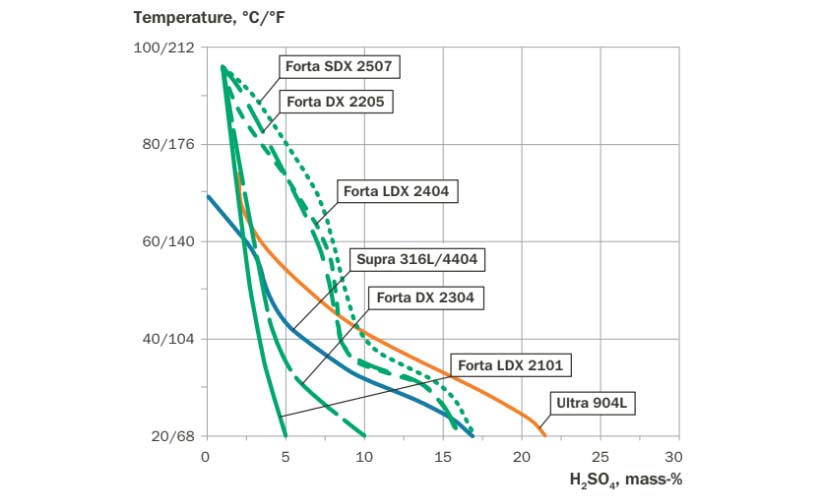

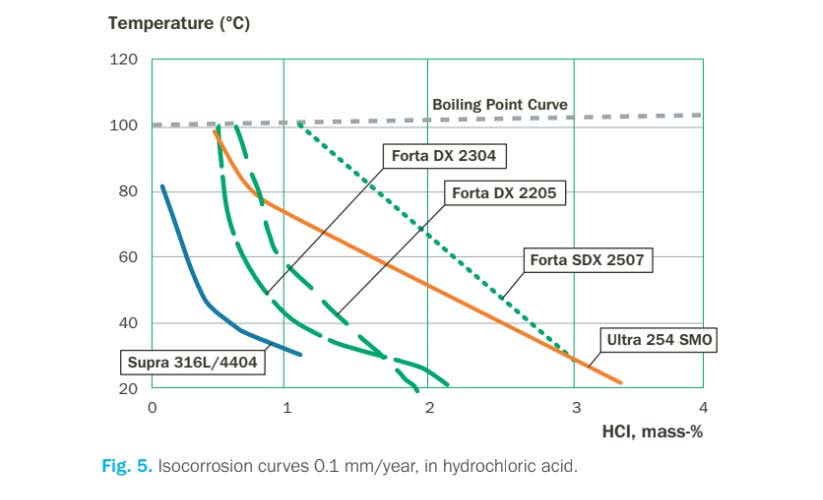

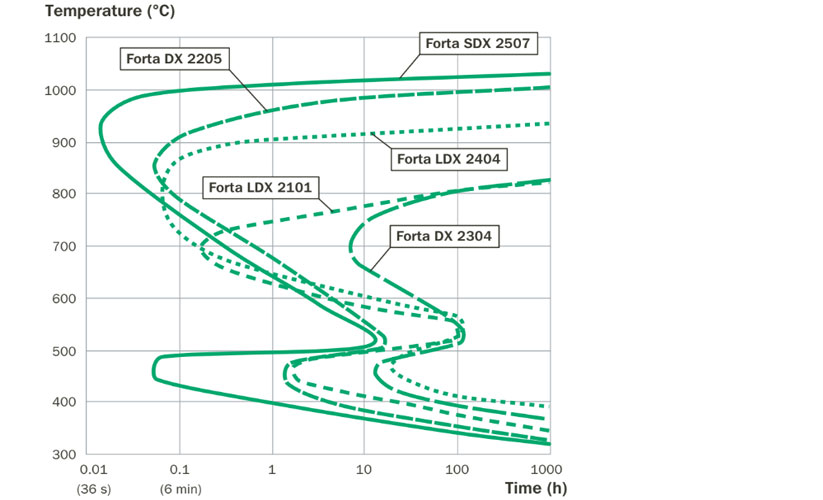

Duplex stainless steels, known for their high chromium content, provide excellent corrosion resistance, particularly in uniform corrosion environments with rates below 0.1 mm/year. Forta DX 2205 shows superior resistance to chloride-contaminated sulfuric acid compared to traditional stainless steels like Supra 316L/4404, approaching the performance of Ultra 904L. In dilute hydrochloric acid, Forta SDX 2507 and similar high-alloyed duplex steels are suitable, though localized corrosion risks exist around crevices even within safe usage limits.

Corrosion resistance

- Uniform Corrosion: Due to high chromium content, these steels resist uniform corrosion well, typically less than 0.1 mm/year.

- Sulfuric Acid: DX 2205 shows superior resistance in sulfuric acid contaminated by chloride ions compared to Supra 316L/4404.

- Hydrochloric Acid: SDX 2507 and DX 2205 can be used in dilute hydrochloric acid, with potential risks of localized corrosion in crevices.

- Nitric Acid: LDX 2101 and DX 2304, with their high chromium content and low molybdenum, are suitable for environments where resistance to strongly oxidizing nitric acid is needed.

PRE values for Forta Duplex grades and some austenitic grades

Steel designations |

PRE |

|||

| name | EN | ASTM Type |

UNS | |

| 2205 | 1.4462 | 2205 | S32205 | 35 |

| 2507 | 1.4410 | 2507 | S32750 | 43 |

Results from stress corrosion cracking immersion tests in chloride solutions

| name | ASTM G123 | ASTM G36 | ||

| 25% NaCl, pH 1.5, 106°C (b.p.), 1,000 h | 40% CaCl2, 100°C, 500 h | 45% MgCl2, 155°C (b.p.), 24 h | ||

| U-bend samples | 4-PB samples (90% of Rp0.2) | U-bend samples | ||

| 2205 | No SCC | No SCC | SCC | |

| 2507 | No SCC | No SCC | SCC | |

Mechanical properties according to EN 10088 and EN 10028

| EN | ASTM | Product form | Yield strength | Tensile | Elongation | Elongation | |

| name | UNS | Rp0.2[MPa] | strength | A[%] | A80[%] | ||

| Rm[MPa] | |||||||

| 2507 | 1.4410 | S32750 | Cold rolled coil (C) | 550 | 750–1000 | 20 | 20 |

| Hot rolled coil (H) | 530 | 750–1000 | 20 | 20 | |||

| Quarto plate (P) | 530 | 730–930 | 20 | 20 | |||

| Bar | 530 | 730–930 | 25 | – | |||

| 1.4510 | S32760 | Cold rolled coil (C) | 550 | 750–1000 | 20 | 20 | |

| Hot rolled coil (H) | 530 | 750–1000 | 25 | 25 | |||

| Quarto plate (P) | 530 | 730–930 | 25 | 25 |

Mechanical properties according to ASTM A240

| EN | ASTM | Product form | Yield | Yield | Tensile | Tensile | Elongation | |

| name | UNS | strength | strength | strength | strength | A50[%] | ||

| Rp0.2[MPa] | Rp0.2 [ksi] | Rm [MPa] | Rm [ksi] | |||||

| 2507 | 1.4410 | S32750 | Plate, sheet and strip | 550 | 80 | 795 | 116 | 15 |

| 100 | 1.4501 | S32760 | Plate, sheet and strip | 550 | 80 | 750 | 108 | 25 |

Mechanical properties at elevated temperatures, minimum yield strength according to EN 10028-7

| name | Strength | 100°C | 150°C | 200°C | 250°C | |

| 2507 | Tensile strength | Rm [MPa] | 680 | 660 | 640 | 630 |

Physical properties

Metric values according to EN 10088-1

| name | EN | ASTM Type | UNS | Density [kg/dm3] | Modulus of elasticity at 20°C [GPa] | Coefficient of thermal expansion 20–100°C [10-6/K] | Thermal conductivity at 20°C [W/(m x K)] | Thermal capacity at 20°C [J/(kg x K)] | Electrical resistivity at 20°C [Ω x mm2/m] |

| 2507 | 1.4410 | 2507 | S32750 | 7.8 | 200 | 13.0 | 15 | 500 | 0.8 |

| 100 | 1.4410 | - | S32760 | 7.8 | 200 | 13.0 | 15 | 500 | 0.8 |

Imperial values converted from Table 10

| name | Density [lbm/in3] | Modulus of elasticity [psi] | Coefficient of thermal expansion 68–212°F [μin / (in x °F)] | Thermal conductivity [Btu/(hr x ft x °F)] | Thermal capacity [Btu/(lbm x °F)] | Electrical resistivity [μΩ x in] |

| 2507 | 0.282 | 29 x 106 | 7.2 | 8.7 | 0.119 | 31.50 |

Fabrication

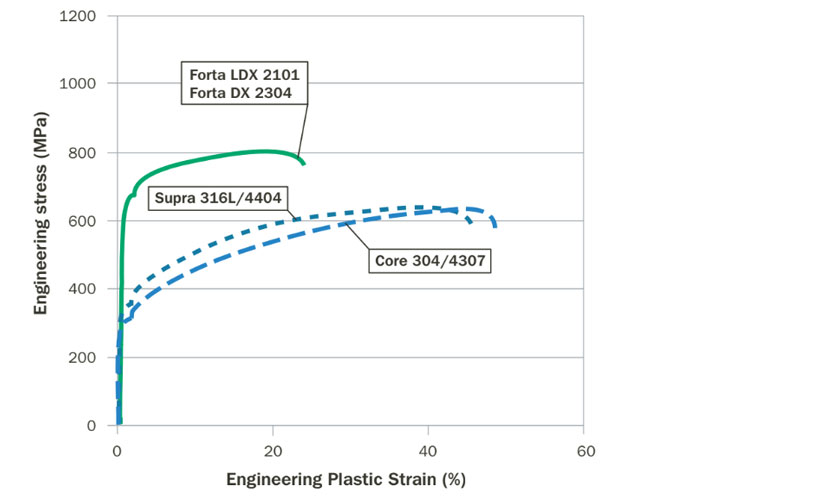

Duplex stainless steel is suitable for all forming processes used for stainless steel. The high yield strength compared to austenitic and ferritic stainless steel can however give differences in forming behavior. Depending on the chosen forming technique there could be consequences, such as increased springback. This point is particularly relevant to the forming of any high strength steel. Moreover, an excellent interplay between high yield strength, work hardening rate and elongation promote the duplex grades for light weight and cost-efficient applications with complex shapes. The impact of the high strength varies for different forming techniques. Common for all is that the estimated forming forces will be higher than for the corresponding austenitic and ferritic stainless steel grades. This effect will usually be lower than expected from just the increase in strength since the choice of duplex stainless steel is often associated with gauge reduction. It is important to consider that duplex stainless steel may also be more demanding on the tools and on the lubricant. This should also be noted when looking to down gauge.

Welding consumables

| name | EN | ASTM Type | UNS | Consumable ISO designation |

| 2507 | 1.4410 | 2507 | S32750 | 25 9 4 NL |

General characteristics

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2507 | 1.4410 | 2507 | S32750 | 43 | 20 | 550 | D | 0.02 | 25.0 | 7.0 | 4.0 | 0.27 |

Product

Quick contact

Get Solution

Organically grow the holistic world view of disruptive innovation via workplace diversity

Contact Us