- Chintamani Stainless Inc, 132, T.P. Streets, 6th Kumbharwada Lane, Mumbai- 400004, India

- Trophy Winning

- Ceritified ( ISO 9005-2010 )

Duplex Round Bar

Chintamani Stainless Inc is ISO 9001:2008 certified manufacturer, supplier and exporter of Duplex Round Bar in India and worldwide. Duplex Steel Round Bar made by Fe-Ni-Cr alloys consisting of ferritic-austenitic microstructure at room temperature. Super Duplex Steel Plates exhibit greater toughness and better weldability than ferritic stainless steel. ASTM A240 Duplex Steel Round Bar has better corrosion resistance and higher strength than austenitic stainless steel Round Bar .

Duplex steels are essentially a combination of properties from both the

ferritic and austenitic groups of stainless steel. Duplex 2205 Round Bar is a

nitrogen-enhanced duplex stainless steel grade. The stainless steel grade 300 is

referred to as Duplex to suit the definition of a family of stainless steels that do not

fall into the categories of fully austenitic grades, such as 304 stainless steel, or

solely ferritic grades, such as 430 stainless steel. The stainless S31803 Duplex Spring

Steel Bar microstructure is composed of austenite pools enclosed by a continuous ferrite

phase. Alloy grade 2205 Duplex Stainless Steel Round Bar was designed to solve typical

corrosion issues with austenitic grade 300 series stainless steels.

The numerous

applications of 2205 Duplex Rod are mentioned below, healthy overall corrosion

tolerance, with a high resistance to chloride stress corrosion cracking,high power,

excellent weldability and workability, resistance to sulphide stress corrosion,

resistance to chloride pitting and crevice corrosion.Duplex 2205 Threaded Rod, which is

useful in a variety of applications, has a lower machinability and cutting velocities

that are about 20% slower than grade 304.

Chloride stress corrosion cracking is

especially prone to the duplex structure. Duplex 2205 Welding Rod has exceptional power

and endurance, as well as strong weldability. The aim of welding any duplex stainless

steel is to achieve fusion and heat-affected zones with the base metal's excellent

corrosion tolerance and sufficiently high impact durability for the application.

We

use high quality alloy that we have gathered from reputable market mills to manufacture

Duplex Steel S32205 Hex bars. Before it is manufactured and used, the alloy that we are

using for product development is carefully inspected to ensure that the quality of the

bars does not deteriorate. We have a team of experts who monitor the production phases

so that all of our employees may receive the right assistance for creating high-quality

bars that meet customer requirements. They are providing guidance to all employees

across all industrial departments in order to develop bars of the highest calibre.

Duplex stainless steels are favored for the multiple properties that they are able to

conjure. This is because of the dual microstructure of the ASTM A276 UNS S31803 Round

Bar. Having a dual microstructure in an alloy gives it an advantage that the said alloy

has characteristics that define both classes of stainless steels. Hence, the inheritance

of the ASTM A479 UNS S31803 Hex Bar would include ductility and resistance to corrosion

from the austenitic class as well as good toughness and hardness from the ferritic

classes.

The benefit of using such an alloy is that despite having good ductility,

the hardness of the alloy prevents the Duplex Steel UNS S31803 Bars from getting

deformed, especially at elevated temperatures, where any conventional steel alloy would

change its shape. This particular characteristic is integral for applications where the

retention of shape is a pre-requisite property. For instance, power generation plants or

even chemical processing industries that have a lot of exothermic reactions require

alloys such as the ASTM A276 F51 Duplex Round Bar, which wouldn’t change shape, despite

the application of heat.

Since these alloys contain nickel in their chemical

composition, the uns s31803 f51 Rods would be able to withstand elevated temperature

conditions. Yet, it is not a practice to use the A276 s31803 material beyond a

temperature of 600° F, as a temperature as high as this could see a drastic drop in its

properties. Yet in comparison to some type of austenitic steels, the behavior exhibited

by the uns s31803 round bar is better at elevated temperatures.

Specification

| UNS S32205 Bars Grade | Duplex 2205 – UNS S32205 |

|---|---|

| Standard | ASME, ASTM, GB, API, DIN, AISI, SUS, EN, UNS |

| WERKSTOFF NR. 1.4462 Round Bars Specification | 2205 Duplex Stainless Steel, ASTM A276 UNS S32205 |

| Duplex 2205 Round Bars size | Diameter: 3-~800mm |

| SAF 2205 Hex Bars size | 2-100mm A/F |

| 2205 Duplex Stainless Steel Flat Bars size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Duplex 2205 Square Bars size | 4 to 100mm |

| Duplex SS 2205 Angle Bars size | 3mm*20mm*20mm~12mm*100mm*100mm |

| UNS S32205 Section | 3.0 to 12.0mm thickness |

| Channel Bars | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Duplex Steel UNS S32205 nickel Hollow Bars | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| 1.4462 Duplex 2205 Billet Size | 1/2" to 495mm Diameter |

| ASTM A276 Type 2205 Rectangles Size | 33 x 30mm to 295 x 1066mm |

| ASTM A276 Type 2205 Round Bars Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Duplex Steel S31803 Round Bars Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Din 1.4462 Round Bars Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

|

Duplex SS 2205 Bars Condition |

Hardened & tempered, annealed |

| c276 Bars Technique | Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bars, Rod |

| 2205 Duplex Stainless Steel Bars Processing | Bars cutting to 650mm |

| Our UNS S32205 Round Bars dealers & distributors are located in | Gimhae-si, Port-of-Spain, Abu Dhabi, Pimpri-Chinchwad, New Delhi, India, Chennai, Santiago, Manama, KhoBars, Howrah, Muscat, Tehran, Noida, Thiruvananthapuram, Ahmedabad, Courbevoie, Nagpur,Indore, Barsoda, Bogota, Calgary, Caracas, Surat, Kolkata, Montreal, Istanbul, Vadodara, Bengaluru, Gurgaon, Gujarat, Janeiro, Karachi, Rajkot, Ahvaz, Mexico Ranchi, Perth, Ernakulam, Sydney, Coimbatore, Melbourne, Dammam, Jamshedpur, Mumbai, Ankara, Ludhiana, Bangalore, London, Riyadh, Hyderabad, Kuwait, Kanpur, Tau, Lagos |

| Our Duplex 2205 Round Bars conforms to NACE MR0175/ISO 15156 | |

ASTM A276 Duplex Steel Duplex Steel F51 Hex Bar Size Range

|

Wt per Foot t of UNS S31803 hex bar

|

Size in Inches of UNS S31803 hex bar

|

Wt per 12 ' of UNS S31803 hex bar

|

|---|---|---|

|

0.0180

|

1/4″

|

2.160

|

|

0.0104

|

3/16″

|

1.248

|

|

0.0600

|

3/8″

|

4.920

|

|

0.0290

|

5/16″

|

3.480

|

|

0.0740

|

1/2″

|

8.880

|

|

0.0560

|

7/16″

|

6.72

|

|

1.150

|

5/8″

|

13.80

|

|

0.0930

|

9/16″

|

11.16

|

|

1.660

|

3/4″

|

19.92

|

|

1.390

|

11/16″

|

16.68

|

|

2.300

|

7/8″

|

27.60

|

|

2.600

|

15/16″

|

31.20

|

|

1.950

|

13/16″

|

23.40

|

|

3.30

|

1-1/16″

|

39.60

|

|

2.90

|

1″

|

34.80

|

|

4.600

|

1-1/4″

|

55.20

|

|

3.700

|

1-1/8″

|

44.40

|

|

5.600

|

1-3/8″

|

67.20

|

|

5.100

|

1-5/16″

|

61.20

|

|

6.600

|

1-1/2″

|

79.20

|

|

6.100

|

1-7/16″

|

73.20

|

|

26.53

|

3″

|

318.36

|

|

9.030

|

1-3/4″

|

108.36

|

|

7.800

|

1-5/8″

|

93.60

|

|

18.42

|

2-1/2″

|

221.04

|

|

11.80

|

2″

|

141.60

|

|

10.0400

|

1-7/8″

|

124.80

|

|

16.920

|

2-3/8″

|

203.04

|

|

14.920

|

2-1/4″

|

179.04

|

ASTM A479 UNS S31803 Finishes

| Bright drawn | BD | Slit rolled edge | SRE |

| Cold drawn | CD | Polished | P |

| Peeled and turned | P&T | Rough turned/peeled | RT |

| Cold finished | CF | Hot rolled pickled and annealed | HRAP |

| Centreless ground | CG | Hot finished | HF |

| Smooth turned | ST | reeled and Peeled | PR |

Duplex Steel UNS S31803 Square Bar Condition

|

H&T

|

Hardened and tempered.

|

|

ANN

|

Annealed

|

|

PH

|

Precipitation hardened.

|

Duplex Steel S31803 Rods Stock List

| Duplex Steel UNS S31803 Round Bars | Duplex Steel F51 Hex Bars |

| ASTM A276 Duplex UNS S31803 Bars | Duplex Steel DIN 1.4462 Round Bars |

| UNS S31803 Duplex Steel Rods | UNS S31803 Duplex Hot Rolled Round Bars |

| Duplex Steel UNS S31803 Bright Bar | Duplex Steel UNS S31803 Forged Round Bars |

Tolerances Of Uns S31803 F51 Rods

| Section/Shape | diameter, Size or width across flats | variation Permitted |

| millimeter | millimeter | |

| Flat (thickness) | < 18 > 30 ≦ 50 > 18 ≦ 30 > 50 ≦ 80 |

+ 0 to - 00.110 + 0 to - 00.250 + 0 to - 00.130 + 0 to - 00.350 |

| Square and hexagon |

> 18 ≦ 30 ≥ 6 ≦ 18 > 50 ≦ 80 > 30 ≦ 50 > 80 ≦ 105 |

+ 0 to - 00.110 + 0 to - 00.090 + 0 to - 00.160 + 0 to - 00.130 + 0 to - 00.250 |

| Round | > 18 ≦ 30 ≥6 ≦ 18 > 50 ≦ 80 > 30 ≦ 50 > 80 ≦ 100 |

+ 0 to - 00.085 + 0 to - 00.070 + 0 to - 00.120 + 0 to - 00.100 + 0 to - 00.140 |

| Flat (width) | < 18 > 30 ≦ 50 > 18 ≦ 30 > 80 ≦ 100 > 50 ≦ 80 > 100 ≦ 130 > 160 ≦ 320 > 130 ≦ 160 |

+ 0 to - 00.110 + 0 to - 00.160 + 0 to - 00.130 + 0 to - 00.220 + 0 to - 00.190 + 0 to - 00.350 + 1.00 to - 1.00 + 0 to - 1.00 |

Equivalent Material Of ASTM A276 UNS S31803 Bar

| STANDARD | UNS | WERKSTOFF NR. |

| UNS S31803 | S31803 | 1.4462 |

Equivalent of ASTM A815 DSS Pipe Elbow

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex 2205 | 1.4462 | S31803 / S32205 |

CHEMICAL COMPOSITION

|

Grade

|

C

|

Mn

|

Si

|

P

|

S

|

Cr

|

Mo

|

Ni

|

N

|

Fe

|

|

S31803

|

0.030 max

|

2.00 max

|

1.00 max

|

0.030 max

|

0.020 max

|

22.0 – 23.0

|

3.0 – 3.5

|

4.50 – 6.50

|

0.14 – 0.20

|

63.72 min

|

|

S32205

|

0.030 max

|

2.00 max

|

1.00 max

|

0.030 max

|

0.020 max

|

21.0 – 23.0

|

2.50 – 3.50

|

4.50 – 6.50

|

0.8 – 0.20

|

63.54 min

|

MECHANICAL PROPERTIES

| S31803 / S32205 | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80000 , MPa – 550 | Psi – 116000 , MPa – 800 | 15 % |

Super Duplex Stainless Steel Pipe Size Chart In Inches

| 1/8″ IPS(.405″ O.D.) | 3 1/2″ IPS( 4.000″ O.D.) |

|---|---|

| SCH 40, 80 | SCH 10, 40, 80, 160, XXH |

| 1/4″ IPS(.540″ O.D.) | 4″ IPS(4.500″ O.D.) |

| SCH 10, 40, 80 | SCH 10, 40, 80, 160, XXH |

| 3/8″ IPS(.675″ O.D.) | 5″ IPS( 5.563″ O.D.) |

| SCH 10, 40, 80 | SCH 10, 40, 80, 160, XXH |

| 1/2″ IPS(.840″ O.D.) | 6″ IPS(6.625″ O.D.) |

| SCH 5, 10, 40, 80, 160, XXH | SCH 5, 10, 40, 80, 120, 160, XXH |

| 3/4″ IPS(1.050″ O.D.) | 8 ” IPS(8.625″ O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH 5, 10, 40, 80, 120, 160, XXH |

| 1″ IPS:(1.315′ O.D.) | 10″ IPS(10.750″ O.D.) |

| SCH 5, 10, 40, 80, 160, XXH | SCH 10, 20, 40, 80 (.500), TRUE 80(.500) |

| 1-1/4″ IPS(1.660″ O.D.) | 12″ IPS(12.750″ O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH 10, 20, 40(.375), TRUE40(.406), SCH80(.500) |

| 1-1/2″ IPS(1.900″ O.D.) | 14″ IPS(14.000″ O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH10 (.188), SCH40 (.375) |

| 2″ IPS(2.375″ O.D.) | 16″ IPS(16.000″ O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH10(.188), SCH40(.375) |

| 2 1/2″ IPS(2.875″ O.D.) | 18″ IPS (18.000″ O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH-40 (.375) |

| 3″ IPS( 3.500″ O.D.) | |

| SCH 5, 10, 40, 80, 160, XXH |

|

|

General characteristics

|

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

|

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2205 | 1.4462 | 2205 | S32205 | 35 | 20 | 500 | D | 0.02 | 22.4 | 5.7 | 3.1 | 0.17 |

| 2205 stainless steel grades | Industry Specifications | UNS |

|

Duplex 2205 2205 (EN 1.4462/UNS S32205 & S31803) |

• Cargo tanks in chemical tankers • Pulp and paper industry applications such as digesters and process tanks • Oil and gas industry, typically tubular products, flanges, fittings and valves • Structural components in bridges |

• Cold rolled coil and sheet • Hot rolled coil and sheet • Quarto plate • Bar • Wire rod • Semi-finished (bloom, billet, ingot & slab) |

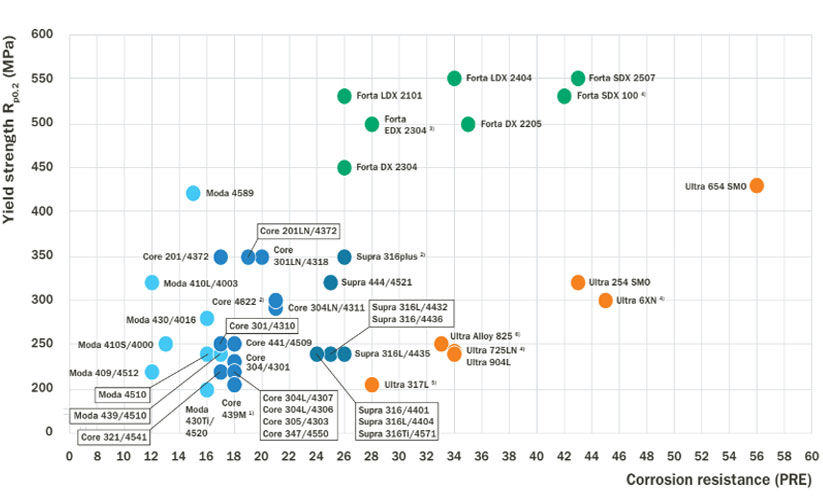

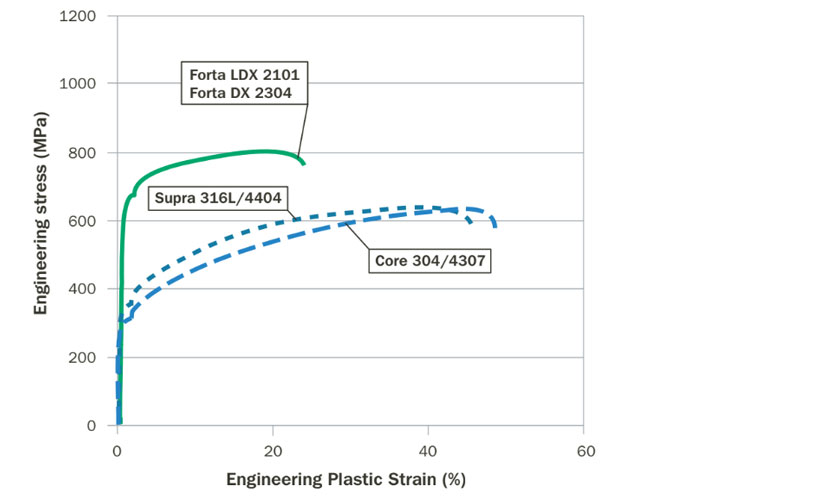

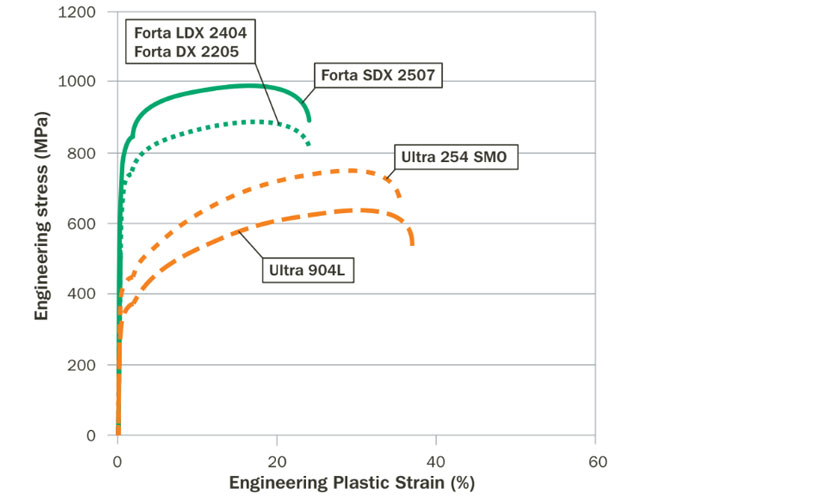

Performance

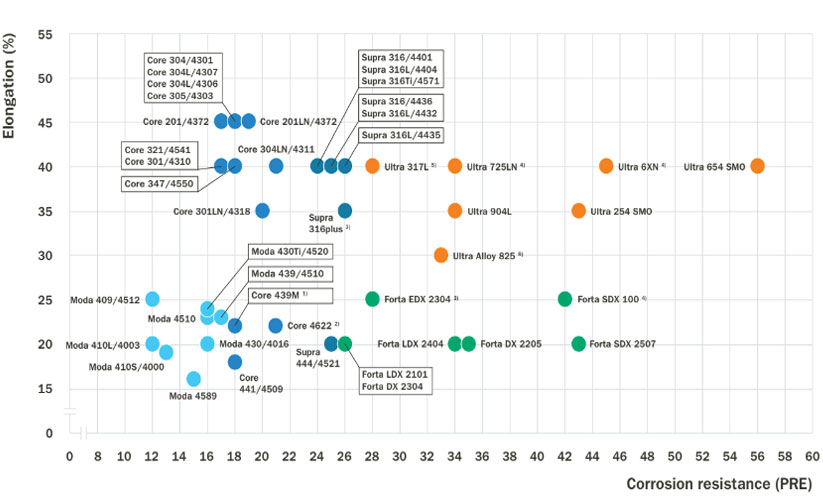

Elongation vs. corrosion resistance.

Elongation vs. Corrosion resistance

Strength vs. Corrosion resistance

Elongation vs. Corrosion resistance

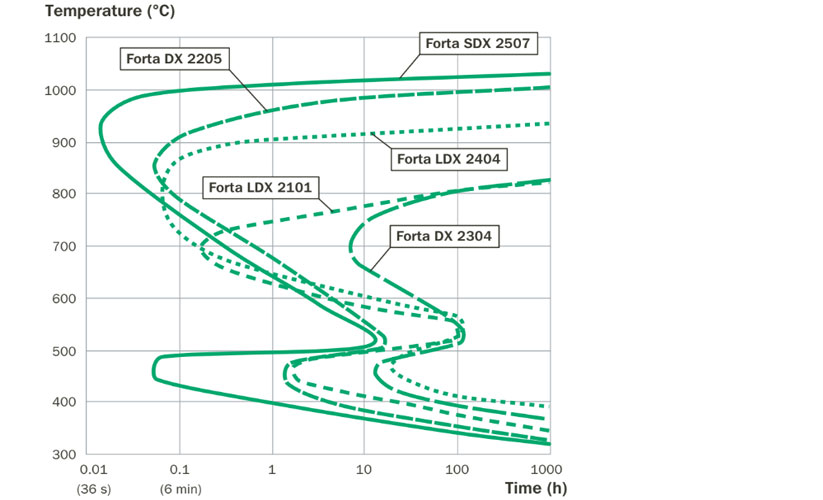

Duplex stainless steels, known for their high chromium content, provide excellent corrosion resistance, particularly in uniform corrosion environments with rates below 0.1 mm/year. Forta DX 2205 shows superior resistance to chloride-contaminated sulfuric acid compared to traditional stainless steels like Supra 316L/4404, approaching the performance of Ultra 904L. In dilute hydrochloric acid, Forta SDX 2507 and similar high-alloyed duplex steels are suitable, though localized corrosion risks exist around crevices even within safe usage limits.

PRE values for Forta Duplex grades and some austenitic grades

|

Steel designations |

PRE |

|||

| name | EN | ASTM Type |

UNS | |

| 2205 | 1.4462 | 2205 | S32205 | 35 |

Results from stress corrosion cracking immersion tests in chloride solutions

| name | ASTM G123 | ASTM G36 | ||

| 25% NaCl, pH 1.5, 106°C (b.p.), 1,000 h | 40% CaCl2, 100°C, 500 h | 45% MgCl2, 155°C (b.p.), 24 h | ||

| U-bend samples | 4-PB samples (90% of Rp0.2) | U-bend samples | ||

| 2205 | No SCC | No SCC | SCC | |

Mechanical properties according to EN 10088 and EN 10028

| EN | ASTM | Product form | Yield strength | Tensile | Elongation | Elongation | |

| name | UNS | Rp0.2[MPa] | strength | A[%] | A80[%] | ||

| Rm[MPa] | |||||||

| 2205 | 1.4462 | S32205 | Cold rolled coil (C) | 500 | 700–950 | 20 | 20 |

| Hot rolled coil (H) | 460 | 700–950 | 25 | 25 | |||

| Quarto plate (P) | 460 | 640–840 | 25 | 25 | |||

| Wire rod 1) | 510 | 750 | 35 | – | |||

| Bar | 450 | 650–880 | 25 | – |

Mechanical properties according to ASTM A240

| EN | ASTM | Product form | Yield | Yield | Tensile | Tensile | Elongation | |

| name | UNS | strength | strength | strength | strength | A50[%] | ||

| Rp0.2[MPa] | Rp0.2 [ksi] | Rm [MPa] | Rm [ksi] | |||||

| 2205 | 1.4462 | S32205 | Plate, sheet and strip | 450 | 65 | 655 | 95 | 25 |

| Wire rod 1) | 510 | 74 | 752 | 109 | – |

Mechanical properties at elevated temperatures, minimum yield strength according to EN 10028-7

| name | Strength | 100°C | 150°C | 200°C | 250°C | |

| 2205 | Yield strength | Rp0.2 [MPa] | 360 | 335 | 315 | 300 |

| Tensile strength | Rm [MPa] | 590 | 570 | 550 | 540 | |

Physical properties

Metric values according to EN 10088-1

| name | EN | ASTM Type | UNS | Density [kg/dm3] | Modulus of elasticity at 20°C [GPa] | Coefficient of thermal expansion 20–100°C [10-6/K] | Thermal conductivity at 20°C [W/(m x K)] | Thermal capacity at 20°C [J/(kg x K)] | Electrical resistivity at 20°C [Ω x mm2/m] |

| 2205 | 1.4462 | 2205 | S32205 | 7.8 | 200 | 13.0 | 15 | 500 | 0.8 |

Imperial values converted from Table 10

| name | Density [lbm/in3] | Modulus of elasticity [psi] | Coefficient of thermal expansion 68–212°F [μin / (in x °F)] | Thermal conductivity [Btu/(hr x ft x °F)] | Thermal capacity [Btu/(lbm x °F)] | Electrical resistivity [μΩ x in] |

| 2205 | 0.282 | 29 x 106 | 7.2 | 8.7 | 0.119 | 31.50 |

Fabrication

Duplex stainless steel is suitable for all forming processes used for stainless steel. The high yield strength compared to austenitic and ferritic stainless steel can however give differences in forming behavior. Depending on the chosen forming technique there could be consequences, such as increased springback. This point is particularly relevant to the forming of any high strength steel. Moreover, an excellent interplay between high yield strength, work hardening rate and elongation promote the duplex grades for light weight and cost-efficient applications with complex shapes. The impact of the high strength varies for different forming techniques. Common for all is that the estimated forming forces will be higher than for the corresponding austenitic and ferritic stainless steel grades. This effect will usually be lower than expected from just the increase in strength since the choice of duplex stainless steel is often associated with gauge reduction. It is important to consider that duplex stainless steel may also be more demanding on the tools and on the lubricant. This should also be noted when looking to down gauge.

Welding consumables

| name | EN | ASTM Type | UNS | Consumable ISO designation |

| 2205 | 1.4462 | 2205 | S32205 | 22 9 3 NL |

General characteristics

|

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

|

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2205 | 1.4462 | 2205 | S32205 | 35 | 20 | 500 | D | 0.02 | 22.4 | 5.7 | 3.1 | 0.17 |

Product

Quick contact

Get Solution

Organically grow the holistic world view of disruptive innovation via workplace diversity

Contact Us