- Chintamani Stainless Inc, 132, T.P. Streets, 6th Kumbharwada Lane, Mumbai- 400004, India

- Trophy Winning

- Ceritified ( ISO 9005-2010 )

Super Duplex Sheet Plate

Chintamani Stainless Inc is ISO 9001:2008 certified manufacturer, supplier and exporter of Super Duplex Steel Plates

in India and worldwide. Super Duplex Steel Sheets made by Fe-Ni-Cr alloys consisting of

ferritic-austenitic microstructure at room temperature. Super Super Duplex Steel Plates exhibit greater

toughness and better weldability than ferritic stainless steel. ASTM A240 Super Duplex Steel Plate has

better corrosion resistance and higher strength than austenitic stainless steel plates.

Super Duplex Plates are mostly used in chemical and petrochemical applications, in power plants due to

their high resistance to localized corrosion as well as to their high strength and toughness. Super

Duplex Steel Perforated Sheets applications should be limited to temperatures below 600° F. Meanwhile,

these Super Super Duplex Plates are also being offered in different sizes and shapes to our customers.

Super Duplex Coil is a combination of molybdenum, chromium, and nitrogen conveys the good resistance of

2205 to chloride pitting and crevice corrosion.

The chemical composition specifications stated in the norm must be met by the steel super duplex uns s32750 / uns s32760 plates. The content, in this case Thick Duplex Alloy 2507 Cold Rolled Sheet, must

also meet the required mechanical properties. Stainless steel mill finished 2507 Super

Duplex Plate was created primarily to handle highly corrosive environments, especially

in situations where high tensile strength properties are needed.

The S32750 Plate has a strong impact intensity as well. But apart from these

characteristics, the super duplex plate has a strong thermal conductivity and a low

coefficient of thermal expansion. But it should be noted that the Super Duplex 2507

Sheet is not generally recommended by manufacturers for applications involving long

exposures to temperatures over 570°F due to the alloy's chance of durability loss. The

advantages of Super Duplex Steel S32750 Plate are as follows: High strength and

resistance to chloride stress corrosion cracking, superior resistance to chloride

pitting and crevice corrosion, low rate of thermal expansion, good weldability and

workability, combination of properties provided by austenitic and ferritic structures.

Flue Gas Scrubbing Equipment, Offshore Oil Production/Technology, Oil and Gas Industry

Equipment, Desalination Equipment, Chemical Process Pressure Vessels, Piping and Heat

Exchangers, Pulp & Paper Mill Equipment, and Marine Applications all utilise Super

Duplex 2507 plate.

The ASTM A240 standard encompasses many chromium and chromium alloy-based stainless steel classes. This specification applies to the aforementioned alloy in the form of ASTM A240 Type Super Duplex 2507 Plate, sheet, or strips. The ASTM A240 listed 5mm Thick Cold Rolled Super Duplex 2507 Sheet has been engineered for use in a variety of applications, including pressure vessels and general applications.

Alloy 2507 is a super duplex stainless steel with 25% chromium, 4% molybdenum, and 7% nickel designed

for demanding applications which require exceptional strength and corrosion resistance, such as chemical

process, petrochemical, and seawater equipment. The steel has excellent resistance to chloride stress

corrosion cracking, high thermal conductivity and a low coefficient of thermal expansion. The high

chromium, molybdenum, and nitrogen levels provide excellent resistance to pitting, crevice, and general

corrosion.

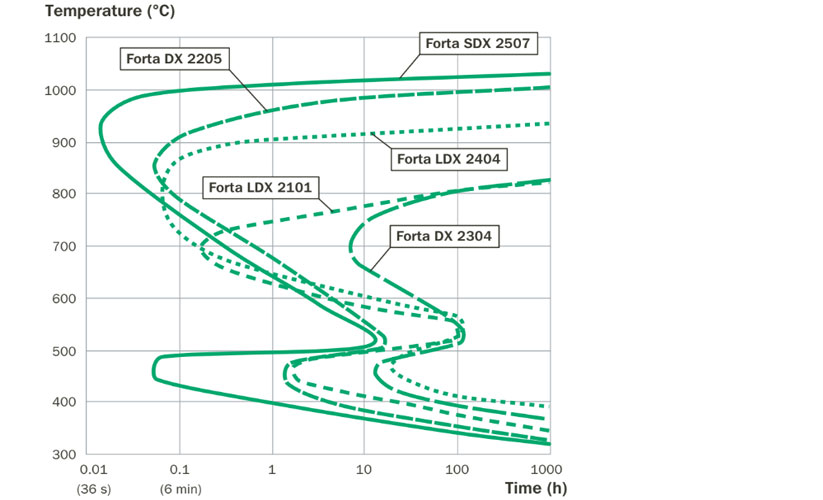

The impact strength is also high. Alloy 2507 is not recommended for applications which require long

exposures to temperatures above 570°F because of the risk of a reduction in toughness.

Super Duplex Alloy UNS S32750 (F53 / 1.4410 / Alloy 32750 / Alloy 2507) combines the most desirable

characteristics of both ferritic and austenitic steels. It has excellent corrosion resistance to a wide

variety of media, with outstanding resistance to pitting and crevice corrosion in seawater and other

chloride containing environments due to its high chromium, molybdenum, and nitrogen level, with Critical

Pitting Temperature exceeding 50°C.

The duplex microstructure gives this grade high strength UNS S32750 a low coefficient of thermal

expansion and higher heat conductivity than austenitic steels and is suitable for working temperatures

up to 300°C.

Listed in NACE MR 01 75 for sour service UNS S32750 and having gained ASME Approval for Pressure Vessel

applications it can be used in a wide variety of applications.

Specification Of Duplex Stainless Steel

| Specification | ASTM A240 / ASME SA240 |

|---|---|

| Standard Industry Specifications |

|

| Material available | 2507 Super Duplex Plate and Sheet |

| Super Duplex 2507 Plate standards and approvals |

|

| Standard Sizes of Saf 2507 Sheet and plate |

1220 x 2440 millimeter, 1000 x 2000 millimeter, 2000 x 2000 millimeter, 1500 x 3000 millimeter, 2000 x 4000 millimeter

|

| UNS S32760 Plate Hardness | Quarter Hard, Soft, Spring Hard, Hard, Half Hard |

| Availability of Saf 2507 Foil sizes | Width: Up to 500 mm (19.5 in) Thickness : 8-100 microns (0.00031-0.004 in) Weight (in rolls) : Up to 50 kg (110 lb); |

| Profiling |

|

| profiles | As per your need |

| Value added services for 1.4410 Plate | Waterjet cutting, welding and Bending , sawing, edge preparation, Laser cutting, Plasma cutting and shearing, mechanical processing |

| Super Duplex Plate Origins | European Origin, Indian Origin, Japanese Origin |

| Super Duplex 2507 Coil services |

|

| Testing conducted | SGS testing, UT, TUV etc |

ASTM A240 Type 2507 Super Duplex Sheet Dimensions Imperial

| Surface finish of Plate | (max in) Width | (in)Gauge |

|---|---|---|

| 2D – heat treated, Cold rolled, pickled plate | 60 | 12–24 |

| Temper rolled plate Mexinox only | 48 | 13–29 |

| 2B – heat treated, Cold rolled, pickled, skin passed Plate | 72* | 10–24 |

| (not brushed) Polished plate | 60 | 11–24 |

| BA Mexinox only | 48 | 18–28 |

SA 240 GR 2507 Super Duplex Sheet

Dimensions in Metric

| Specification | ASTM A240 / ASME SA240 |

| Dimension Standard | MSRR, AMS, BS, JIS, AISI, ASTM, GB, DIN, EN, etc |

| Size Range | Cold rolled Grades Super Duplex Steel Plates 0.5-6.4 mm Hot rolled Grades Super Duplex Steel Plates 3.0–10.0 mm |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Thickness | 0.3 mm to 120 mm |

| Finish | No.1, 2B, 2D, 2R, HR. |

| Hardness | Half Hard, Soft, Hard, Quarter Hard, Spring Hard |

| Value Added Service | Cladding, Heat Treatment, Annealed, Pickling, Polish, Rolling, Cutting, Bending, Forging, Minor Fabrication Etc. |

| Dealers & Distributor of | SAIL, ESSAR, JINDAL, TATA, BHUSHAN, INDIAN, POSCO, JISCO, TISCO, LISCO, BAOSTEEL IMPORTED material |

| Profiling | Plasma Plate Cutting Laser Plate Cutting Oxy-propane Flame Cutting |

ASTM A240 Super Duplex Sheet Equivalent Material

| STANDARD | UNS | WERKSTOFF NR. |

| Super Duplex S32750 | S32750 | 1.4410 |

| Super Duplex S32760 | S32760 | 1.4410 |

2507 Stainless Steel Sheet Density

| Density | lb/in3 | 0.28 |

|---|---|---|

| Modulus of Elasticity | psi x 106 | 29 |

| Coefficient of Thermal Expansion 68-212°F/°F |

x10-6/°F | 7.2 |

| Thermal Conductivity | Btu/h ft °F | 8.7 |

| Heat Capacity | Btu/lb/°F | 0.12 |

| Electrical Resistivity | W-in x 10-6 | 31.5 |

Melting Point of Duplex 2507 Sheet

| Grade | Melting point |

|---|---|

| 2507 | 2460° F (1350° C) |

Weight chart of Duplex 2507 Plate

| Thickness | Plate Weight per Unit Area | Density |

|---|---|---|

| 3/16 inches | 0.06000 lbs/in²42.184176 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1/4 inches | 0.08 lbs/in²56.245568 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3/8 inches | 0.121 lbs/in²85.0714216 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1/2 inches | 0.161 lbs/in²113.1942056 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 5/8 inches | 0.196 lbs/in²137.8016416 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3/4 inches | 0.235 lbs/in²165.221356 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 7/8 inches | 0.274 lbs/in²192.6410704 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 inches | 0.313 lbs/in²220.0607848 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 1/4 inches | 0.391 lbs/in²274.9002136 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 1/2 inches | 0.47 lbs/in²330.442712 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 3/4 inches | 0.549 lbs/in²385.9852104 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 inches | 0.627 lbs/in²440.8246392 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 1/4 inches | 0.705 lbs/in²495.664068 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 1/2 inches | 0.784 lbs/in²551.2065664 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 3/4 inches | 0.862 lbs/in²606.0459952 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3 inches | 0.941 lbs/in²661.5884936 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

ASTM A240 TYPE 2507 Sheet Dimension

Duplex 2507 Plate Metric Dimensions

| Surface finish | Thickness (mm) | Width (mm) |

|---|---|---|

| 2B – Cold rolled, heat treated, pickled, skin passed | 0.25–8.0 | max. 2032 |

| 2D – Cold rolled, heat treated, pickled | 0.4–6.35 | max. 1524 |

| 2E – Cold rolled, heat treated, mechanically descaled | 0.4–8.0 | max. 2032 |

| 2R – Cold rolled, bright annealed | 0.25–3.5 | max. 1524 |

| 2H – Work hardened | 0.4–6.35 | max. 1524 |

| Polished, brushed | 0.5–4.0 | max. 1524 |

Imperial Dimensions of ASTM A240 TYPE 2507 Sheet

| Surface finish | Gauge (in) | Width (in) |

|---|---|---|

| 2B – Cold rolled, heat treated, pickled, skin passed | 10–24 | max. 72* |

| 2D – Cold rolled, heat treated, pickled | 12–24 | max. 60 |

| BA Mexinox only | 18–28 | max. 48 |

| Polished (not brushed) | 11–24 | max. 60 |

| Temper rolled Mexinox only | 13–29 | max. 48 |

Super Duplex 2507 Plate Chemical Composition

|

Cr

|

Others

|

C

|

N

|

Mo

|

Ni

|

|---|---|---|---|---|---|

|

25

|

S=0.001

|

0.020

|

.27

|

4.0

|

7

|

Saf 2507 Plate Physical Properties

| Elasticity | psi x 106 | 29 |

|---|---|---|

| Heat | Btu/lb/°F | 0.12 |

| Density | lb/in3 | 0.28 |

| Resistivity | W-in x 10-6 | 31.5 |

| Thermal Conductivity | Btu/h ft °F | 8.7 |

| Coefficient of Thermal Expansion |

x10-6/°F | 7.2 |

Mechanical Strength Table

| 0.2% Yield Strength | Elongation | Tensile Strength | Hardness |

|---|---|---|---|

| 65 Minimum | 25 Minimum | 90 Minimum | 293 Maximum |

ASTM A240 Gr S32750 Sheet Tensile & Yield Properties

| Tensile | Yield | Elongation | Hardness |

|---|---|---|---|

| MPa min | MPa min | % min | Brinell max |

| 795 | 550 | 15.25% | 310 |

| Grade | UNS | EN | W-Nr | DIN | AFNOR | SS |

|---|---|---|---|---|---|---|

| 2507 | S32750 | Super Duplex DIN 1.4410 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 |

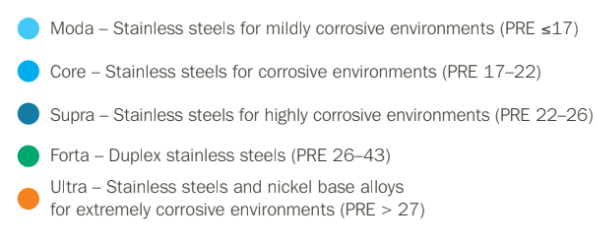

General characteristics

|

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

|

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2507 | 1.4410 | 2507 | S32750 | 43 | 20 | 550 | D | 0.02 | 25.0 | 7.0 | 4.0 | 0.27 |

| 2205 stainless steel grades | Industry Specifications | UNS |

| Duplex 2507 2507 (EN 1.4410/UNS S32750) A super duplex product with higher corrosion resistance and mechanical strength than Forta DX 2205. Often used in extremely corrosive environments. |

• Desalination plants • Industrial piping • Scrubbers • Oil and gas industry, typically tubular products, flanges,fittings and valves • Deep-sea pipelines |

• Cold rolled coil and sheet • Hot rolled coil and sheet • Quarto plate • Bar • Wire rod • Semi-finished (bloom, billet, ingot & slab) |

| Duplex 32760 100 (EN 1.4501/UNS S32760) A super duplex product with higher corrosion resistance and mechanical strength than Forta DX 2205. Often used in extremely corrosive environments. |

• Desalination plants • Industrial piping • Scrubbers • Oil and gas industry, typically tubular products, flanges, fittings and valves • Deep-sea pipelines |

• Cold rolled coil and sheet • Hot rolled coil and sheet • Quarto plate • Bar • Wire rod • Semi-finished (bloom, billet, ingot & slab) |

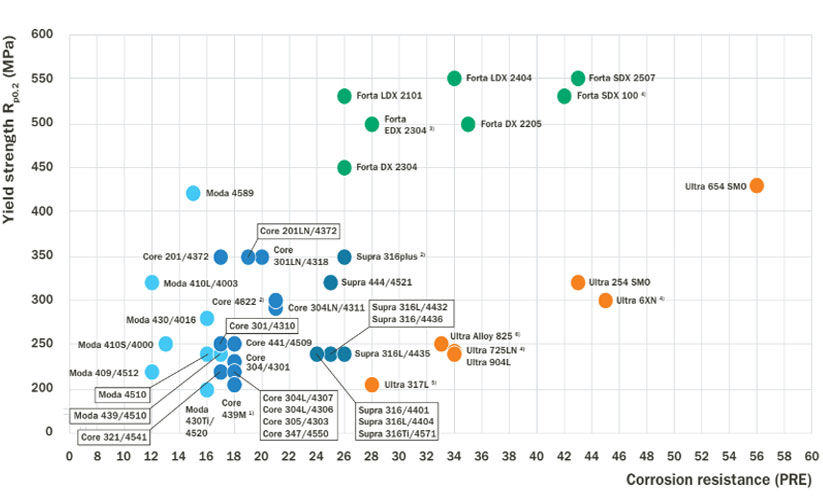

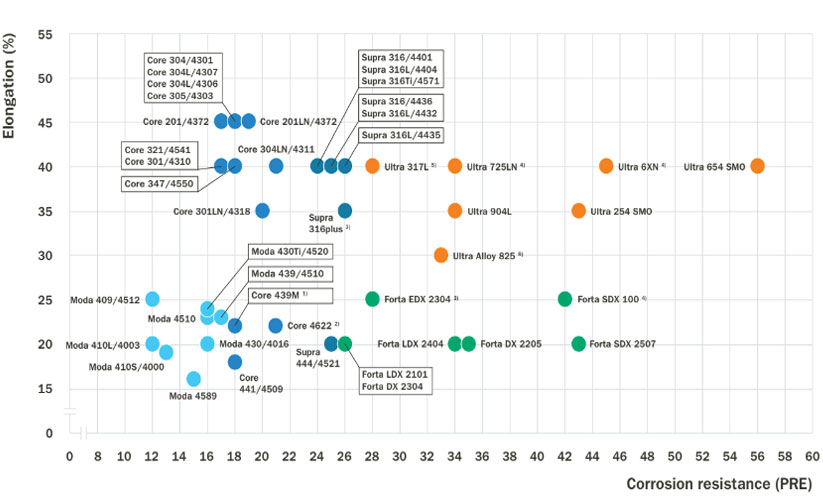

Performance

Elongation vs. corrosion resistance.

Elongation vs. Corrosion resistance

Strength vs. Corrosion resistance

Elongation vs. Corrosion resistance

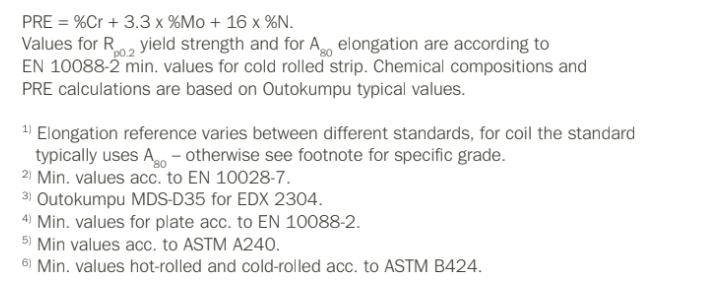

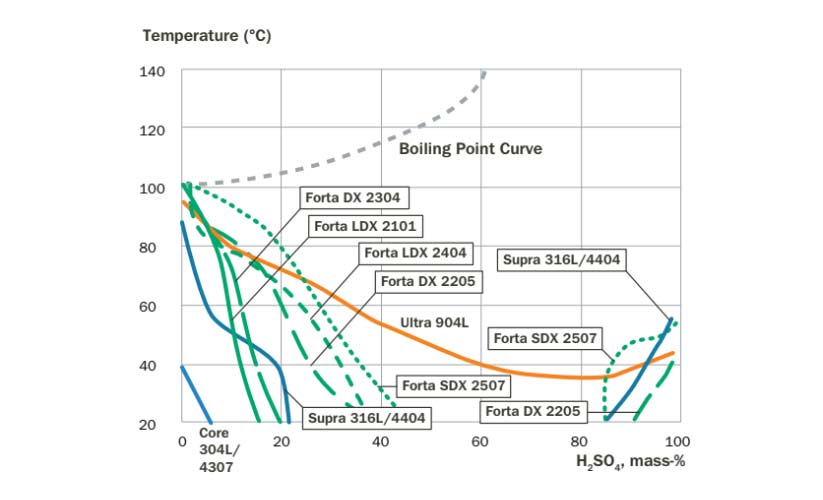

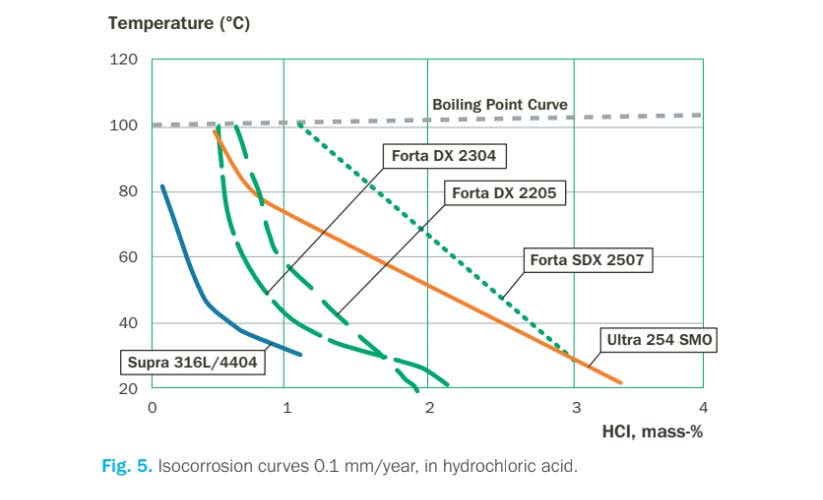

Duplex stainless steels, known for their high chromium content, provide excellent corrosion resistance, particularly in uniform corrosion environments with rates below 0.1 mm/year. Forta DX 2205 shows superior resistance to chloride-contaminated sulfuric acid compared to traditional stainless steels like Supra 316L/4404, approaching the performance of Ultra 904L. In dilute hydrochloric acid, Forta SDX 2507 and similar high-alloyed duplex steels are suitable, though localized corrosion risks exist around crevices even within safe usage limits.

Corrosion resistance

- Uniform Corrosion: Due to high chromium content, these steels resist uniform corrosion well, typically less than 0.1 mm/year.

- Sulfuric Acid: DX 2205 shows superior resistance in sulfuric acid contaminated by chloride ions compared to Supra 316L/4404.

- Hydrochloric Acid: SDX 2507 and DX 2205 can be used in dilute hydrochloric acid, with potential risks of localized corrosion in crevices.

- Nitric Acid: LDX 2101 and DX 2304, with their high chromium content and low molybdenum, are suitable for environments where resistance to strongly oxidizing nitric acid is needed.

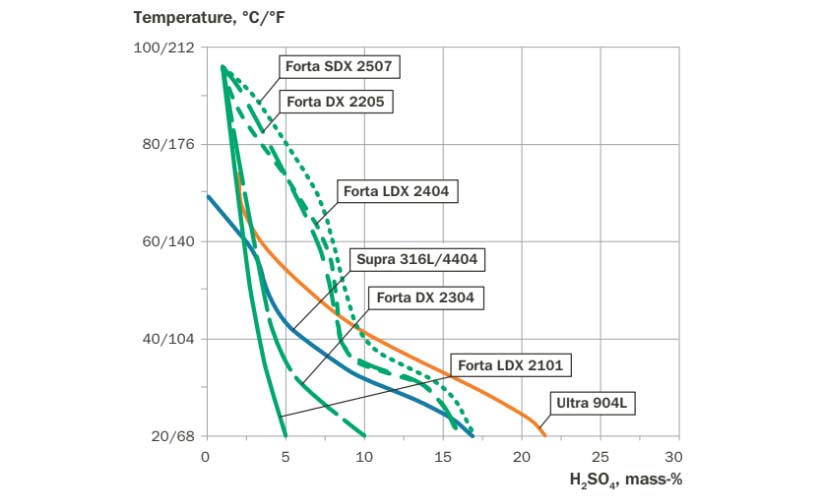

PRE values for Forta Duplex grades and some austenitic grades

|

Steel designations |

PRE |

|||

| name | EN | ASTM Type |

UNS | |

| 2205 | 1.4462 | 2205 | S32205 | 35 |

| 2507 | 1.4410 | 2507 | S32750 | 43 |

Results from stress corrosion cracking immersion tests in chloride solutions

| name | ASTM G123 | ASTM G36 | ||

| 25% NaCl, pH 1.5, 106°C (b.p.), 1,000 h | 40% CaCl2, 100°C, 500 h | 45% MgCl2, 155°C (b.p.), 24 h | ||

| U-bend samples | 4-PB samples (90% of Rp0.2) | U-bend samples | ||

| 2205 | No SCC | No SCC | SCC | |

| 2507 | No SCC | No SCC | SCC | |

Mechanical properties according to EN 10088 and EN 10028

| EN | ASTM | Product form | Yield strength | Tensile | Elongation | Elongation | |

| name | UNS | Rp0.2[MPa] | strength | A[%] | A80[%] | ||

| Rm[MPa] | |||||||

| 2507 | 1.4410 | S32750 | Cold rolled coil (C) | 550 | 750–1000 | 20 | 20 |

| Hot rolled coil (H) | 530 | 750–1000 | 20 | 20 | |||

| Quarto plate (P) | 530 | 730–930 | 20 | 20 | |||

| Bar | 530 | 730–930 | 25 | – | |||

| 1.4510 | S32760 | Cold rolled coil (C) | 550 | 750–1000 | 20 | 20 | |

| Hot rolled coil (H) | 530 | 750–1000 | 25 | 25 | |||

| Quarto plate (P) | 530 | 730–930 | 25 | 25 |

Mechanical properties according to ASTM A240

| EN | ASTM | Product form | Yield | Yield | Tensile | Tensile | Elongation | |

| name | UNS | strength | strength | strength | strength | A50[%] | ||

| Rp0.2[MPa] | Rp0.2 [ksi] | Rm [MPa] | Rm [ksi] | |||||

| 2507 | 1.4410 | S32750 | Plate, sheet and strip | 550 | 80 | 795 | 116 | 15 |

| 100 | 1.4501 | S32760 | Plate, sheet and strip | 550 | 80 | 750 | 108 | 25 |

Mechanical properties at elevated temperatures, minimum yield strength according to EN 10028-7

| name | Strength | 100°C | 150°C | 200°C | 250°C | |

| 2507 | Tensile strength | Rm [MPa] | 680 | 660 | 640 | 630 |

Physical properties

Metric values according to EN 10088-1

| name | EN | ASTM Type | UNS | Density [kg/dm3] | Modulus of elasticity at 20°C [GPa] | Coefficient of thermal expansion 20–100°C [10-6/K] | Thermal conductivity at 20°C [W/(m x K)] | Thermal capacity at 20°C [J/(kg x K)] | Electrical resistivity at 20°C [Ω x mm2/m] |

| 2507 | 1.4410 | 2507 | S32750 | 7.8 | 200 | 13.0 | 15 | 500 | 0.8 |

| 100 | 1.4410 | - | S32760 | 7.8 | 200 | 13.0 | 15 | 500 | 0.8 |

Imperial values converted from Table 10

| name | Density [lbm/in3] | Modulus of elasticity [psi] | Coefficient of thermal expansion 68–212°F [μin / (in x °F)] | Thermal conductivity [Btu/(hr x ft x °F)] | Thermal capacity [Btu/(lbm x °F)] | Electrical resistivity [μΩ x in] |

| 2507 | 0.282 | 29 x 106 | 7.2 | 8.7 | 0.119 | 31.50 |

Fabrication

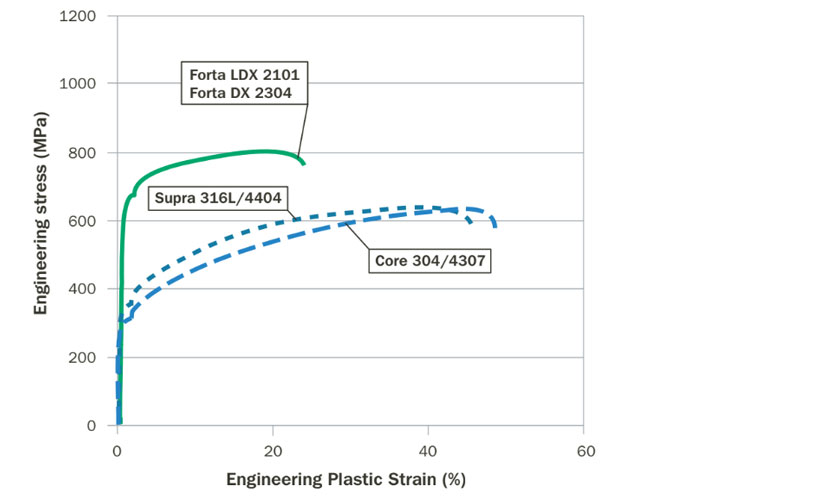

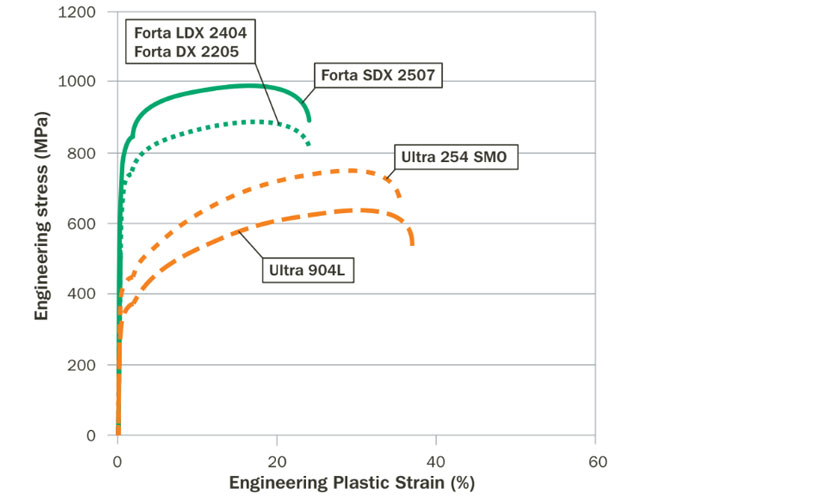

Duplex stainless steel is suitable for all forming processes used for stainless steel. The high yield strength compared to austenitic and ferritic stainless steel can however give differences in forming behavior. Depending on the chosen forming technique there could be consequences, such as increased springback. This point is particularly relevant to the forming of any high strength steel. Moreover, an excellent interplay between high yield strength, work hardening rate and elongation promote the duplex grades for light weight and cost-efficient applications with complex shapes. The impact of the high strength varies for different forming techniques. Common for all is that the estimated forming forces will be higher than for the corresponding austenitic and ferritic stainless steel grades. This effect will usually be lower than expected from just the increase in strength since the choice of duplex stainless steel is often associated with gauge reduction. It is important to consider that duplex stainless steel may also be more demanding on the tools and on the lubricant. This should also be noted when looking to down gauge.

Welding consumables

| name | EN | ASTM Type | UNS | Consumable ISO designation |

| 2507 | 1.4410 | 2507 | S32750 | 25 9 4 NL |

General characteristics

|

Steel designations |

Performance |

Typical chemical composition, % by mass |

||||||||||

|

name |

EN |

ASTM |

UNS |

PRE |

A1) |

Rp0.2 |

Grade |

C |

Cr |

Ni |

Mo |

N |

| 2507 | 1.4410 | 2507 | S32750 | 43 | 20 | 550 | D | 0.02 | 25.0 | 7.0 | 4.0 | 0.27 |

Product

Quick contact

Get Solution

Organically grow the holistic world view of disruptive innovation via workplace diversity

Contact Us